E-PAC5,8,1.5,HCP2-1008

Printed in USA

©2008

TVW

Page 6

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

CONTROLS

START/STOP CONTROL (electric motor option only)

When the pressure in the air receiver reaches a designated low level, approximately 110 P.S.I.G. (drawing 9.9 Amps), the pres-

sure switch starts the motor. When the pressure in the air receiver reaches a designated high level, approximately 135 P.S.I.G., the

pressure switch stops the motor. Single stage compressors cut in at approximately 105 P.S.I.G. and cut out at approximately 125

P.S.I.G

.

NOTE: An electric motor should not be subjected to more than fi fteen (15) starts per hour. Damage to the

equipment will result.

CONSTANT SPEED CONTROL

The electric motor or gasoline engine is constantly running and the pump on the compressor is constantly pumping. When the

pressure in the air receiver reaches the designated high level, approximately 127 P.S.I.G., a pilot unloader valve will channel the

air being compressed into the atmosphere instead of into the air receiver. During this step, the motor or the engine, continues to

run (engine will idle). When the designated low pressure in the air receiver is reached, approximately 105 P.S.I.G. (drawing 9.9

Amps), the pilot unloader valve will redirect the air being compressed to the air receiver (the engine speed will return to the high

RPM level).

NOTE: All gasoline units must be built this way and any electrical units can be ordered with constant speed

control

.

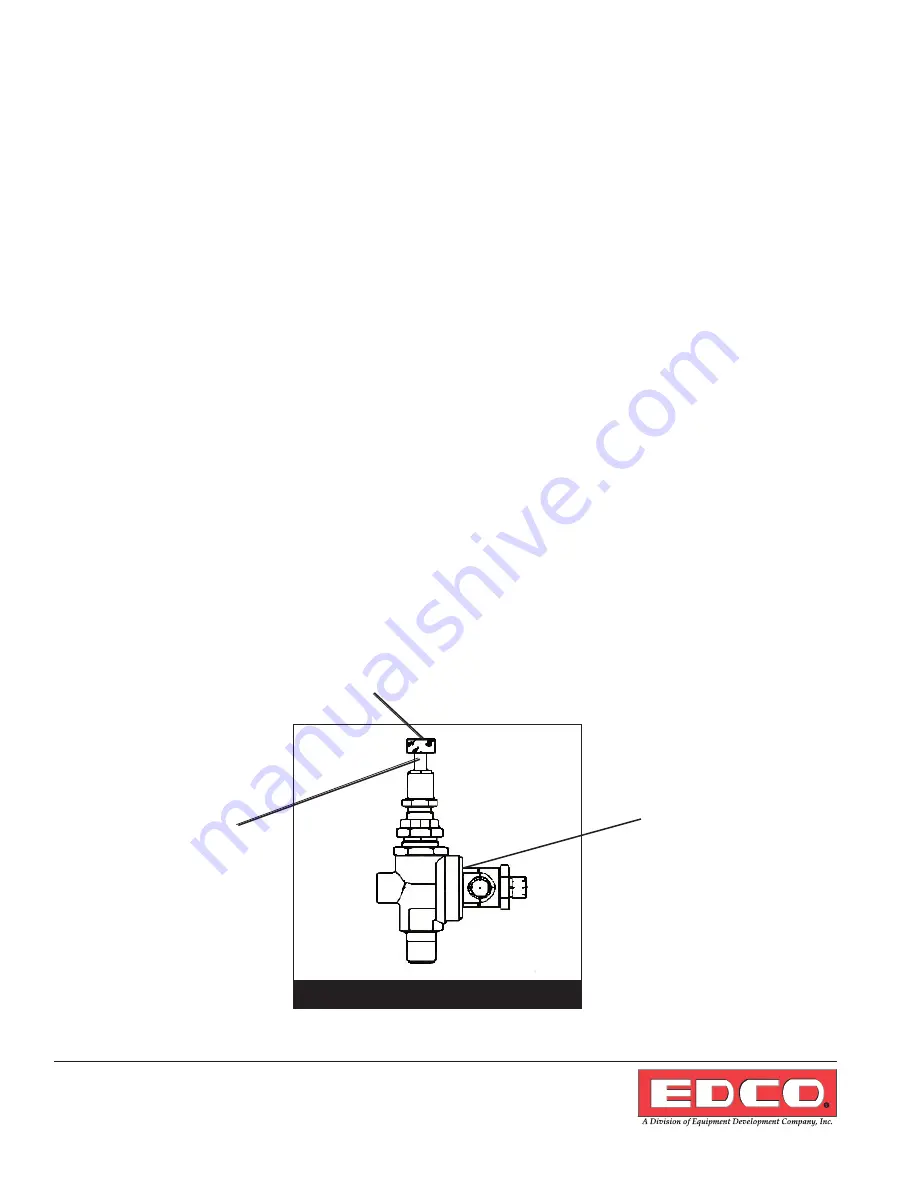

DUAL CONTROL

Compressors can be equipped with both start-stop and constant speed controls. With this feature the operator can change the

control of the unit as their needs change from start-stop to constant speed. (See Figure 2).

COLD-STARTING PROCEDURE

Cold weather conditions present starting problems for air compressors. As operating temperatures decrease, the oil weight used in

the air pump must be thinned according to the OIL TYPE TABLE on page 7.

It is also necessary to remove the effects of the back pressure (load) on a cold motor. A drain cock is installed on the 90º “fi nned”

aftercooler as a means to eliminate the load. Open the aftercooler drain cock and allow the motor and the pump to run “unloaded”

for one to two minutes. Repeat the procedure if the motor continues to struggle.

Available on electric with

dual control option only.

Figure 2

FOR START/STOP:

Rotate thumbscrew

completely clockwise.

Pilot

Unloader

Valve

FOR CONSTANT SPEED:

Rotate thumbscrew completely

counter-clockwise.

Electric

models

only