9

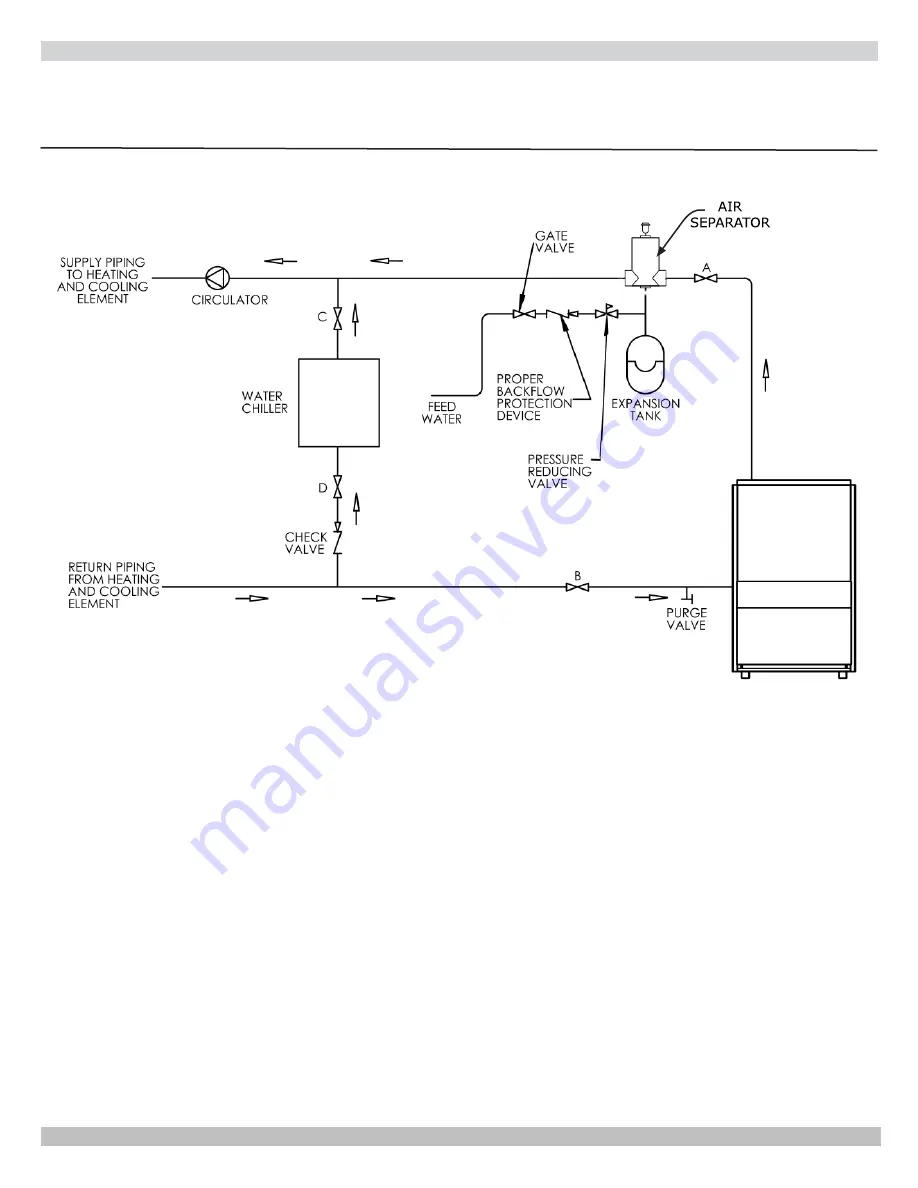

Circulators in following illustrations are mounted on system supply side, mounting on system return side is also accept-

able practice.

1.

Boiler used in connection with refrigeration system,

install so chilled medium is piped in parallel with boiler

with appropriate valves to prevent chilled medium from

entering boiler. See Figure 2.

2.

Boiler piping system of hot water boiler connected to

heating coils located in air handling units where they

may be exposed to refrigerated air circulation must be

equipped with

fl

ow control valves or other automatic

means to prevent gravity circulation of boiler water

during cooling cycle.

3.

Hot water boilers installed above radiation level or

as required by authority having jurisdiction must be

provided with low water cut-off device.

4.

Boiler connected to heating system utilizing multiple

zoned circulators, each circulator must be supplied with

fl

ow control valve to prevent gravity circulation.

5.

Hot water boilers and system must be

fi

lled with water

and maintained to minimum pressure of 12 psi.

6.

Bypass piping is optional which gives ability to

adjust supply boiler water temperature to

fi

t system

or condition of installation. This method of piping,

however, is not typically required for baseboard heating

systems. Typical installations where bypass piping is

used are as follows:

A. This method is used to protect boilers from

condensation forming due to low temperature

return water. Generally noticed in large converted

gravity systems or other large water volume

systems. Figures 4 and 5

.

B. These methods are used to protect systems using

radiant panels and material they are encased in

from high temperature supply water from boiler

and protect boiler from condensation.

NOTE#1:

When using bypass piping, adjust

valves V1 & V2 until desired system temperature

is obtained. See Figure 5, page 9.

NOTE#2:

Bypass loop must be same size piping

as supply and return piping.

4 - CONNECTING SUPPLY AND RETURN PIPING

Figure 3 - Circulators Mounted on Supply System, Boiler Used In Confi guration with Chiller System.

See Special Conditions, Page 9

Summary of Contents for Olsen OMGB II Series

Page 18: ...18 10 WIRING DIAGRAM Figure 14 Integrated High Limit Electronic Ignition Control 240008781 ...

Page 19: ...19 10 WIRING DIAGRAM Figure 15 Integrated High Limit Electronic Ignition Control 240008781 ...

Page 29: ...NOTES ...

Page 30: ...NOTES ...

Page 31: ...Date Service Performed Company Name Tech Initials Company Address Phone ...

Page 32: ...ECR International 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...