20

ECOWATER

S Y S T E

M S

Service Information

continued from page 19

Use the recharge keypad to manually advance the

valve into each cycle and check correct switch op-

eration, and observe the valve position indicator.

NOTE:

The position switch is closed when the

plunger is depressed, open when extended.

While in this diagnostic screen, the following infor-

mation is available and may be beneficial. This infor-

mation is retained by the computer from the first time

electrical power is applied to the faceplate.

...

Remote:

either Installed or Not Installed.

...

Days:

displays the number of days this faceplate

has had electrical power applied.

...

Rchg:

to show the number of regenerations initi-

ated by this faceplate since power was first applied.

NOTE: This number resets to 0 if the model code is

changed.

...

Last Rchg:

displays the number of days since last

recharge.

...

Cap:

displays numerically the capacity the soften-

er is operating at with 1 lowest and 5 highest.

Press the SELECT/EXIT (

↵

) to exit to the Ad-

vanced/Service menu, move cursor up to EXIT and

press SELECT/EXIT (

↵

) to go to Normal Screen

Views.

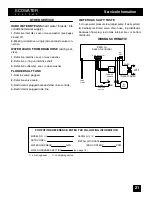

TROUBLESHOOTING,

MANUAL ADVANCE REGENERATION CHECK

This check verifies proper operation of the gearmo-

tor, brine tank fill, brine draw, regeneration flow

rates, and other controller functions.

Always make

the initial checks, and the manual initiated diagnos-

tics first.

1.

Press the RECHARGE keypad. Move cursor

down to Start Rchg Now and press SELECT/EXIT

(

↵

) to start a recharge. As the EcoWater Systems

conditioner enters the fill cycle of regeneration, re-

move the brinewell cover and, using a flashlight, ob-

serve fill water entering the tank.

a.

If water does not enter the tank, look for an ob-

structed nozzle and venturi, fill flow plug or brine tub-

ing FIGURE 7, page 17.

2.

After verifying fill, press Recharge keypad to

move the valve into brining*. A slow flow of water to

the drain will begin. Verify brine draw from the brine

tank by shining the flashlight into the brinewell and

observing a noticeable drop in the liquid level.

*If the 2ND BACKWASH option is set, the valve will

enter backwash and fast rinse before brining...see

page NO TAG.

NOTE: Be sure water is in contact with the salt, and

not separated by a salt bridge...see page 17.

a.

If the unit does not draw brine, check for...

...

dirty or defective nozzle and venturi, page 17

...

nozzle and venturi not seated on the gasket, or

gasket defective

...

restriction in valve drain, causing a back-pressure

(bends, kinks, elevated too high, etc.), installation

step 7, page 7

...

obstruction in brine valve or brine tubing, page

NO TAG and FIGURE 5, page 7

...

inner valve failure (obstructed outlet disc, wave

washer defective, etc.)

3.

Again press Recharge keypad to move the valve

into backwash. Look for a fast flow of water from the

drain hose.

a.

If flow is slow, check for a plugged top distributor,

backwash flow plug or drain hose.

4.

Press Recharge keypad to move the valve to fast

rinse position. Again look for a fast drain flow. Allow

the unit to rinse for several minutes to flush out any

brine that may remain from the brining cycle test.

5.

To return the valve to service position, press Re-

CHARGE ONCE AGAIN.

continued