INSTALLATION INSTRUCTIONS

Position the desalination system in a cool and dry location. Mount the system using all four mounting

holes.

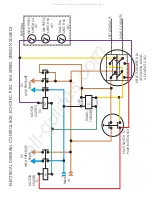

The electrical installation should only be done by a professional electrician. Check the correct

voltage before installing the system.

The cable labeled with the system’s voltage and frequency is to be connected to the power supply. The

cable marked “FEED PUMP” is to be connected to the feed pump or should be insulated / removed

where pressurized seawater is available.

SEAWATER FEED PUMP (Optional Equipment)

Mount the feed pump in a dry location below the waterline of the vessel. Connect the intake of the feed

pump with the vessel’s sea strainer. Connect the outlet of the feed pump with the intake of the

desalination system located at the pre-filter assembly. Secure all hoses with the supplied hose clamps.

PRODUCT WATER TUBING

Connect the product water outlet marked “SAMPLE” with a test station of your choice. Connect the

product water outlet marked “TANK” to your storage tank.

REJECT WATER TUBING/HOSE

Connect the outlet of the pressure control valve on the back of the flow control panel with the 1/2”

reinforced PVC hose to a thru hull fitting preferably above the waterline or drain of your choice.

FRESH WATER FLUSH KIT

Install the fresh water flush filter housing at a location near to the desalination system. Connect the flush

port of the three-way service valve at the pre-filter assembly of the desalination system with the outlet of

the flush filter housing marked “OUT”. Supply pressurized fresh water to the shut off valve of the fresh

water flush filter housing.

All manuals and user guides at all-guides.com