5

EBARA

PUMPS AMERICAS CORPORATION

www.pumpsebara.com

(t) 803.327.5005 (f) 803.327.5097

rev. 01/21

EBARA Submersible Sewage Pumps

Operating, Installation, and Maintenance

DL3FU / DL3MFU / DL3KFU / DL3KMFU / DDL3FU / DV3FU/ DML3FU

INSTRUCTION MANUAL

P.4

PM32U

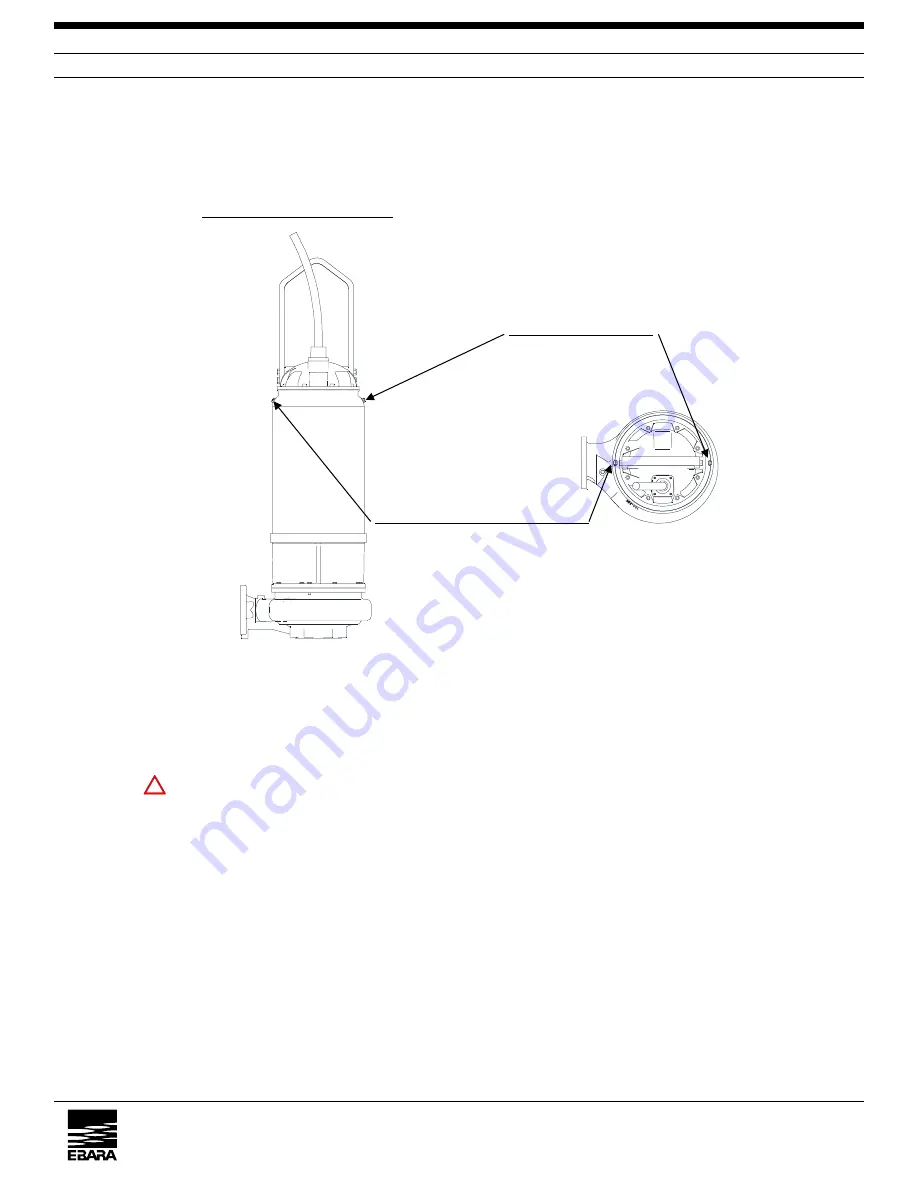

3.1.1 Internal Liquid Supply (Figs. 1, 2 and 3)

2~5HP(1.5-3.7kW) models come standard without internal cooling system and are shipped with proper

oil capacity per Table 2. 7.5~60HP(5.5~45kW) are standard with internally cooled system (no oil fill

required) and are shipped with proper coolant capacity per Table 1.

Fig. 1 Fig. 2

The motor shaft is sealed with a mechanical seal. The coolant chamber provided between the

two sealing stages can be filled with coolant by standing the pump vertical

on a level surface

and remove plugs

“

Coolant supply hole

”

and

“

Air vent & full level check hole

”

.

CAUTION:

THE SEAL CHAMBER MAY BE UNDER PRESSURE. HOLD A RAG OVER

THE PLUG TO PREVENT SPLATTER.

Pour the specified coolant into the coolant chamber through

“

Coolant supply hole

”

until the

coolant flows out of

“

Air vent & full level check hole

”

. (See Table 1)

After the coolant chamber is filled to the specified level, plug the two holes.

!

Air vent & full level check hole

50%: Propylene Glycol

50%: Water

Coolant supply hole

COOLANT (Internal liquid)