9

C. Adding Fluid To The System

When hydraulic fluid is added to replenish the system, it

should always be poured through a fine wire screen (200

mesh or finer).

It is important that the fluid be clean and free of any

substance which could cause improper operation or wear of

the motor or other hydraulic units. Therefore, the use of cloth

to strain the fluid should be avoided to prevent lint from

getting into the system.

D. Lubrication

Internal lubrication is provided by system oil flow.

E. Replacement Parts

Reliable operation throughout the specified operating range

is assured only if genuine Vickers parts are used. Part

numbers are shown in the parts drawings listed in Table 1.

F. Product Life

The longevity of these products is dependent upon

environment, duty cycle, operating parameters and system

cleanliness. Since these parameters vary from application to

application, the ultimate user must determine and establish

the periodic maintenance required to maximize life and

detect potential component failure.

G. Troubleshooting

Table 4 lists the common difficulties experienced with vane

motors and hydraulic systems. It also indicates the probable

causes and remedies for each of the troubles listed.

It should always be remembered that many apparent motor

failures are actually due to the failure of other parts of the

system. The cause of improper operation is best diagnosed

with adequate testing equipment and a thorough understand-

ing of the complete hydraulic system.

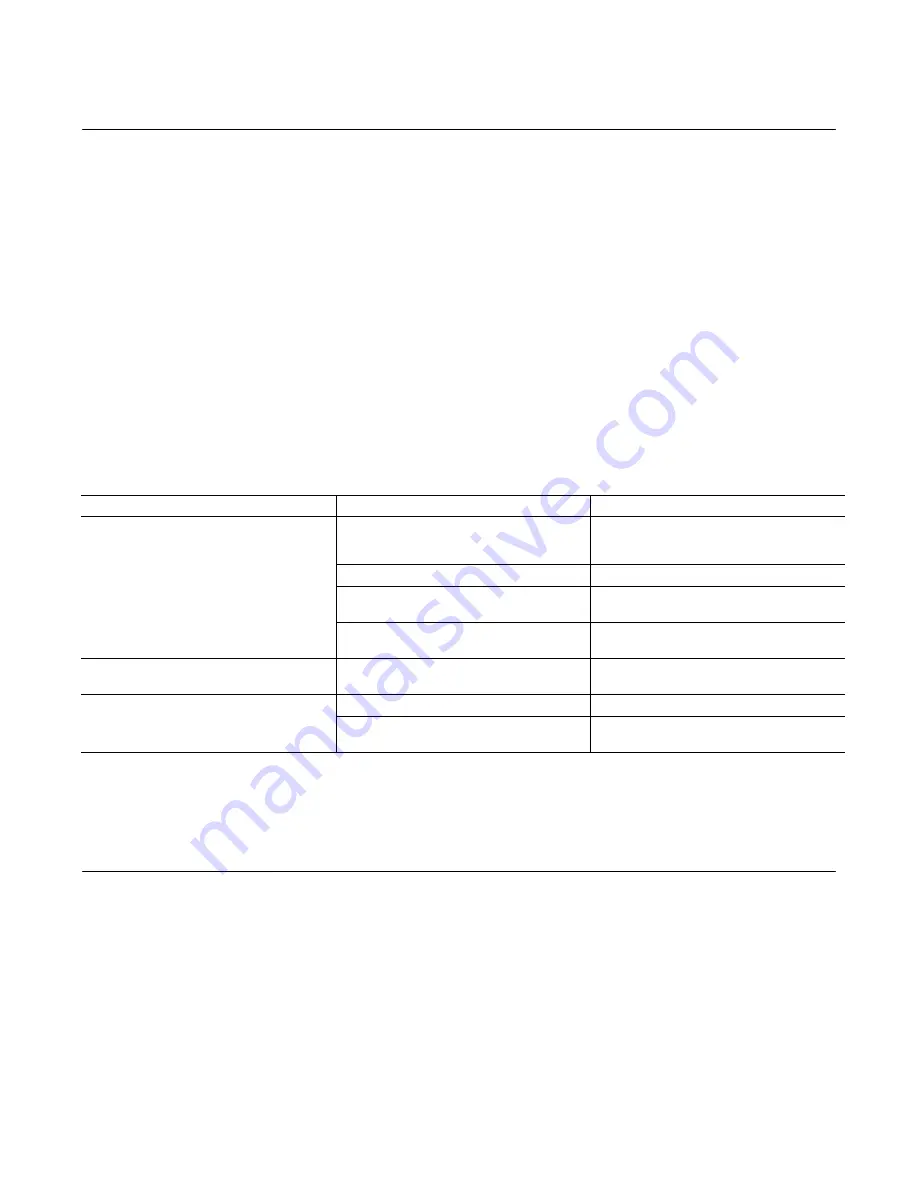

TROUBLE

PROBABLE CAUSE

REMEDY

Motor not developing sufficient speed or

torque.

Insufficient fluid pressure.

Check delivery of motor. Make certain

sufficient hydraulic fluid is available to the

motor. Check motor drive speed.

System overload relief valve set too low.

Check pressure and reset relief valve.

Motor requiring excessive torque.

Remove motor and check torque

requirements of drive shaft.

Parts of motor cartridge scored due to

excessive pressure or foreign matter in oil.

Remove motor for overhaul.

Motor shaft continuing to rotate when control

is in

‘

OFF

’

position.

Control valve is not functioning properly.

Check control valve for correct spool and

leakage.

Motor turning in wrong direction.

Improper port connections at valve plate.

Reverse port connections.

Components in system not functioning as

intended.

Check complete system for proper operation.

Table 5. Troubleshooting Chart.

Section VI

–

Overhaul

A. General

Plug all removed units and cap all lines to prevent the entry

of dirt into the system during shutdown. During disassembly,

pay particular attention to identification of the parts for correct

assembly.

Figure 7 is an exploded view which shows the proper

relationship of the parts for disassembly and assembly.

Figure 1 can be referred to for the correct assembled

relationship.

B. Disassembly

Be certain the unit is not subjected to pressure. Disconnect

and cap all lines before removing the motor from its

mounting. Remove the flanges, screws and o-rings from

M2-500 series motors.

1.

Cover End.

Place the motor on blocks cover end up.

Remove the four cover screws and washers and lift off the

cover.

Remove the o-ring from the groove in the cover. Remove the

pressure plate and wave washer from the cover and remove

the o-ring from the pressure plate.

Do not

disassemble the

shuttle valves unless it is necessary to replace them

because of leakage.

Lift off the ring and locating pins. Remove the vanes and

rotor sub-assembly.