5

Section III

–

Principles of Operation

A. General

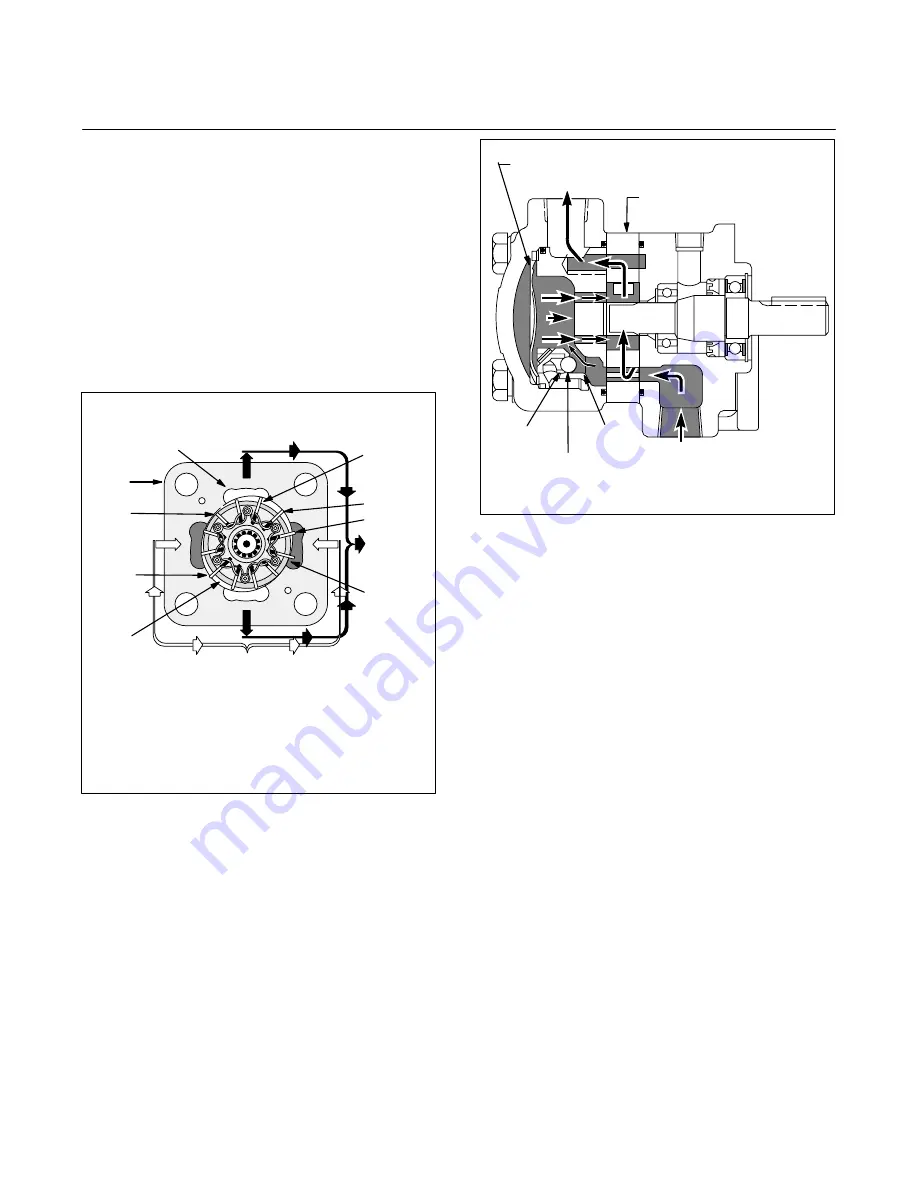

Rotation of the motor shaft is caused by fluid flow

through the motor exerting a force against the vanes.

This force is in effect tangential to the rotor and causes

the rotor to turn, carrying the motor shaft with it.

If fluid is directed into the motor from the body port (see

Figure 2), shaft rotation, as viewed from the head end, is

counterclockwise. When the cover port is used for the inlet,

rotation clockwise as viewed from the cover end. Changing

the direction of fluid flow thus changes the direction of motor

rotation. This is usually accomplished by the use of a

suitable directional control valve. With either port open to

pressure, the other port becomes the return port.

As viewed from cover end:

Rotation is counterclockwise when body port is inlet.

Rotation is clockwise when cover port is inlet.

ÂÂÂ

ÂÂÂ

ÂÂÂ

ÂÂÂÂÂ

ÂÂÂÂÂ

ÂÂÂÂÂ

ÂÂÂÂÂ

ÂÂÂÂÂ

Kidney Slot

Cover End View

Ring

Vane

Rotor

From Body Port

To Cover

Port

1

2

3

4

9

A

A1

B

B1

Figure 2.

B. Cartridge Action

High pressure oil entering the body port (see Figure 3) is

divided by internal coring and is directed into chambers

between the vanes through kidney slots A and A1 (see

Figure 2). The chambers between vane 2 and vane 3 are

supplied with high pressure oil from port A. The chambers

between vane 3 and vane 4 are at a lower pressure because

they are open to discharge port B. Counterclockwise rotation

of the rotor and vane assembly results from the difference in

pressure across vane 3. This action is duplicated on vane 9.

As any two successive vanes pass the A and A1 slots,

fluid between them is trapped and carried to the B and

B1 slots. Here, the distance between the rotor and ring

is decreasing, and the fluid flows into low pressure

kidney slots and is directed through internal coring to

tank.

ÄÄÄ

ÄÄÄ

ÄÄÄ

ÄÄÄ

Wave Washer

Cover

Drive Cartridge

Seat

Seat

Body

Shuttle

Valve

Figure 3.

It can be readily seen from Figure 2 that if the direction

of flow is reversed, B and B1 will become pressure

chambers and the direction of shaft rotation will be

reversed.

C. Hydraulic Balance

Regardless of whether A and A1 or B and B1 are high

pressure chambers, equal pressure will always be present in

any two chambers 180 degrees apart. Thus, hydraulic loads

against the shaft cancel each other out and the unit is in

hydraulic balance.

D. Rocker Arms

Rocker arms (Figure 4) are required to hold the vanes

outward against the ring until system pressure builds up.

They also aid in keeping the vanes against the ring when the

pressure is at a high level (see

E. Pressure Plate

below).

These arms move about a pivot pin attached to the rotor. The

ends of each arm support tow vanes 90 degrees apart.

Action is such that as one vane (A) is being forced into its

rotor slot by the ring, the other (B) is forced out by the rocker

arm. Although the arm exerts a certain amount of spring

tension against the vanes, flexing is virtually eliminated by

the rocking action as the arm swivels on its pin.

E. Pressure Plate

The pressure plate serves two purposes. It seals the cover

end of the cartridge against internal leakage and it contains

porting to feed system pressure to the base of the vanes to

hold them out against the ring.