10

c. Make sure “O” ring (22) and back-up ring (21) are

assembled correctly. Position as shown in Figure 8. Apply a

small amount of system fluid to screws (24) and thread

screws into cartridge kit. Install cartridge kit 920) into body

(38).

7. Install “O” ring (36) over cartridge kit (20) and into

“O” ring groove of body (38).

8. Line up the two cartridge kit pins (26) with the holes in

housing (19) and then install the housing. Position the

housing according to punch marks made during step C.2 of

Disassembly procedure. Attach housing to the body with four

screws (18). Torque the screws to specifications noted in

Table 4.

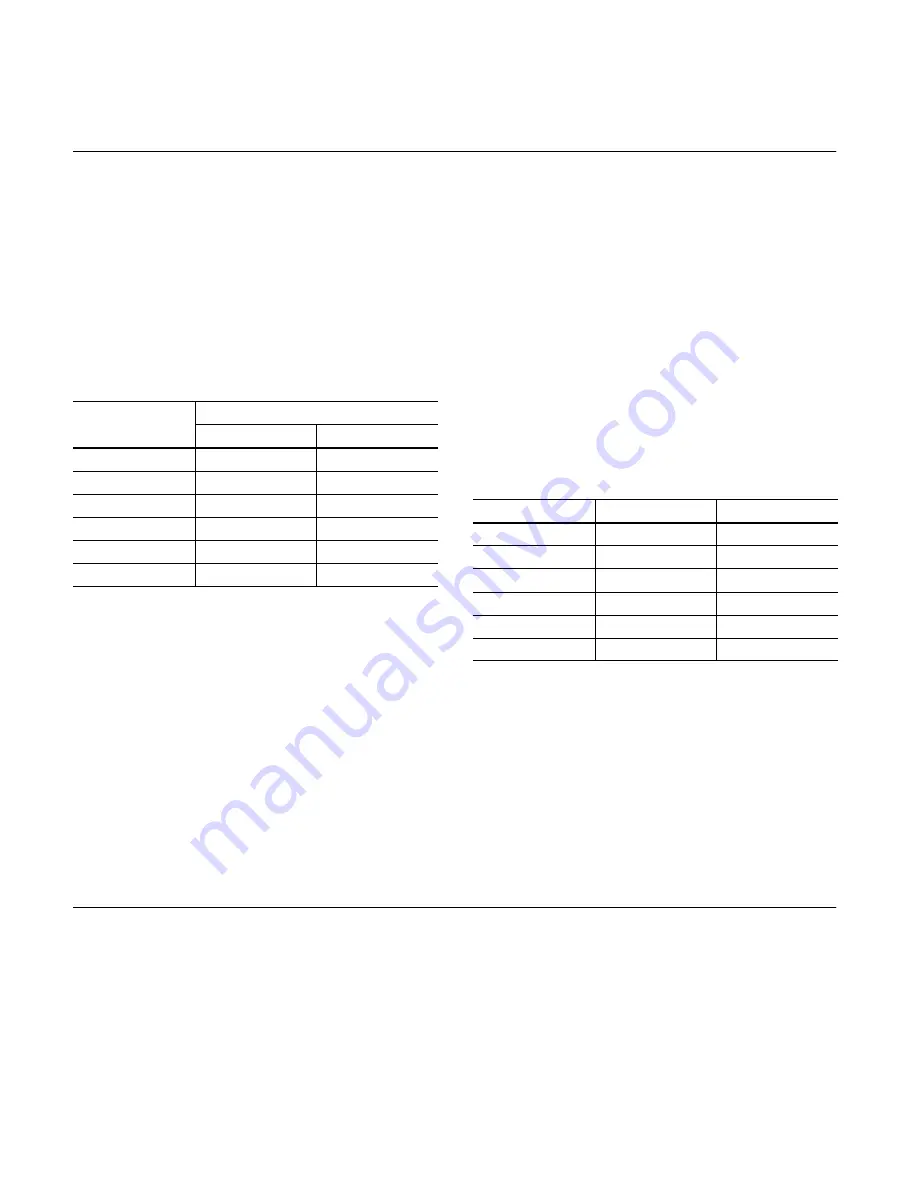

Torque Specification

Model

N.m

lb.ft.

2520V

48–55

65–75

3520V

102–118

140–160

3525V

102–118

140–160

4520V

188–203

255–275

4525V

188–203

255–275

4535V

–

–

Table 4. Torque specifications for screw (18)

9. If cartridge kit (6) is replaced with a new kit, line up

pins (13) with holes in housing (19) and install kit into

housing. If cartridge kit requires assembly, assemble in

reverse order of disassembly. During assembly, note the

following precautions.

a. Make sure the rotation arrows on the rotor (15)

and ring (14) are in direction of pump rotation.

b. Be certain the sharp edges of vanes (16) lead in

direction of pump rotation.

c. Make sure “O” ring (9) and back-up ring (8) are

assembled in the correct position (Figure 8).

NOTE

Cartridge kit (6) is assembled into housing (19) in

the reverse manner of cartridge kit (20). Make sure

the rotation arrow of the ring points in direction of

rotation.

d. Apply a small amount of hydraulic fluid to screws

(11) and thread screws into cartridge kit.

10. Install sealing ring (10) into cover (5).

11. Install “O” ring (7) over cartridge kit (6) against the

housing face.

12. Position cover (5) over cartridge kit (6) according to

the prick marks made during step C.2 of disassembly

procedures. Install cover (5) and secure with screws (4).

Torque screws (4) to specifications noted in Table 5.

Model

N.m

lb.ft.

2520V

54–68

40–50

3520V

54–68

40–50

3525V

88–102

65–75

4520V

54–68

40–50

4525V

88–102

65–75

4535V

188–203

255–275

Table 5. Torque specifications for screw (4)

13. Install key (3) into groove on shaft (34).

14. Place pump into mounting bracket (2) and secure

with two screws (1).

Section VII – Start-Up and Test

A. Start-Up

Install the unit into the system. Make sure that the drive shaft

is aligned properly, all connections are tight and the hydraulic

oil source is open to pump inlet. If an overhead reservoir is

used, purge air from inlet line.

The pump should prime almost immediately with a minimum

drive speed of 600 RPM. Intermittently operate (jog) the

pump until it primes. It may be necessary to loosen the outlet

fitting temporarily to purge trapped air. Failure of the pump to

prime in a short period of time indicates incorrect assembly

or restricted flow from the reservoir.

B. Test

Use your hydraulic system to test the unit. Refer to the

installation drawings listed in Table 1 for recommended

speeds and pressures. If more precise testing is desired,

consult your Vickers sales engineering office.