7

Substitutes may result in early failure. Part numbers are

shown in the parts drawings listed in Table 1.

Repair Kits – Commonly replaced parts are usually provided

in the form of a kit (Figure 4). It is recommended that all such

parts be replaced with the kit when a unit is overhauled.

CAUTION

Individual cartridge parts ARE NOT

interchangeable with similar parts of previous

design models. Complete cartridge kits ARE

interchangeable with previous designs.

F. Product Life

The longevity of these products is dependent upon envi-

ronment, duty cycle, operating parameters and system

cleanliness. Since these parameters vary from applica-

tion to application, the ultimate user must determine and

establish the periodic maintenance required to maximize

life and detect potential component failure.

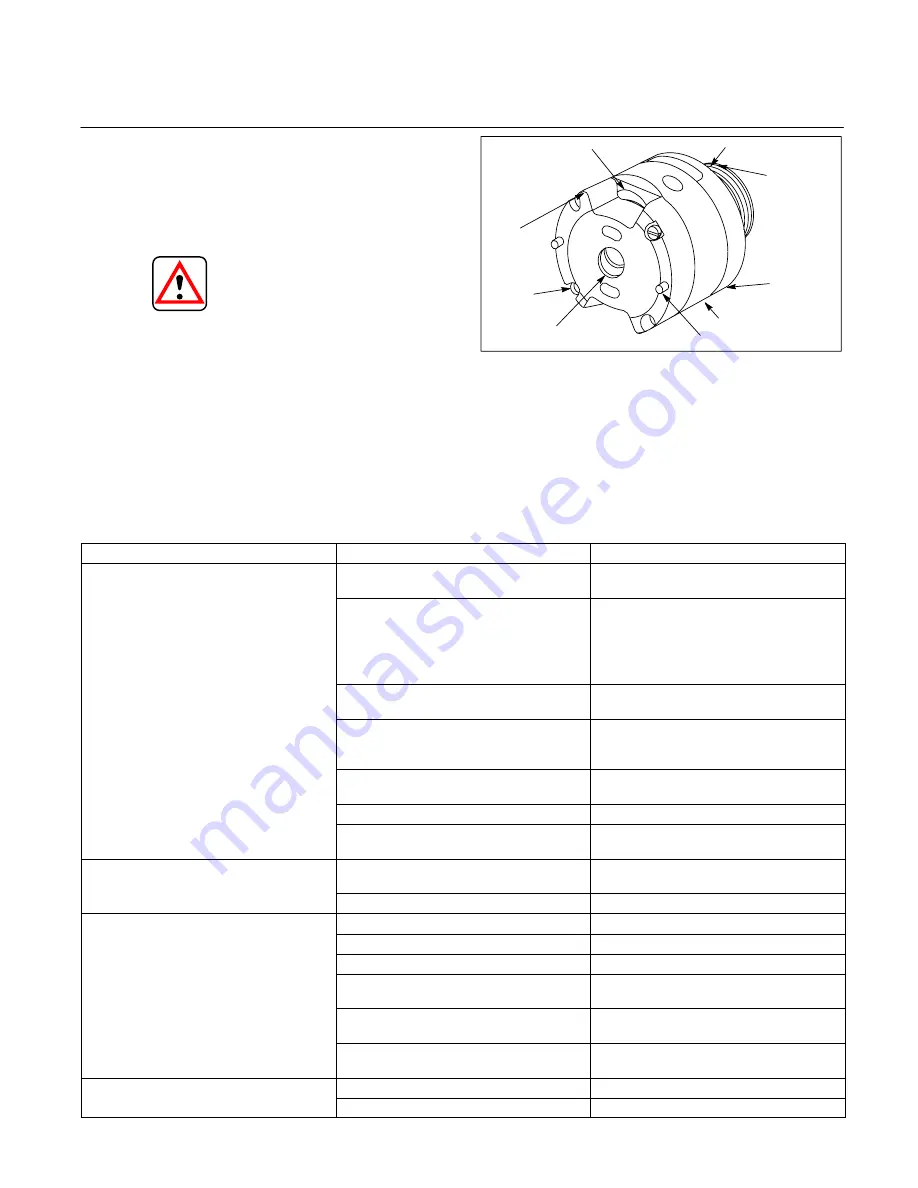

Rotor, vane and

intra-vane

assembled

inside ring

Inlet

Support

Plate

Screw

Bushing

Location Pin

Ring

Outlet

Support

Plate

Sealing Ring

Back-up

Ring

and O-ring

Figure 4. Pre-assembled cartridge kit

G. Troubleshooting

Table 3 lists the common difficulties experienced with vane

pumps and hydraulic systems. It indicates probable causes

and remedies for each of the troubles listed.

TROUBLE

PROBABLE CAUSE

REMEDY

Excessive noise in pump.

Low oil level in reservoir.

Fill reservoir to proper level with

recommended fluid.

Air in system.

Open reservoir cap and operate system

until purged.

Bleed hydraulic lines at highest point

down stream of pump while system is

under pressure.

Vacuum condition.

Check inlet (suction) line and fittings for

air leaks.

Oil too thick.

Be certain correct type of oil is used in

system. Warm up pump in cold weather

until noise disappears.

Damaged or missing pump seals at

mating surfaces.

Locate and replace damaged or missing

seals.

Cartridge kit not assembled properly.

Reassemble cartridge kit.

Pump inlet/outlet lines reversed.

Replumb lines to proper port

connections.

Pump overheating.

Internal leakage.

If excessive internal leakage exists,

return to shop for complete overhaul.

Heat exchanger not functioning.

Locate trouble and repair or replace.

System not developing pressure.

Relief valve open.

Repair or replace.

y

g

Loss of fluid internally (slippage).

Return to shop for evaluation and repair.

Cartridge kit not assembled properly.

Reassemble kit.

Cartridge kit assembled for opposite

rotation.

Reassemble kit to proper rotation.

Pump inlet/outlet lines reversed.

Replumb lines to proper port

connections.

Disconnected or broken drive

mechanism.

Locate and repair.

Loss of fluid.

Ruptured hydraulic lines.

Locate and repair.

Leaking or missing seals.

Locate and repair.

Table 3. Troubleshooting Chart