4

Instruction Booklet

IB015001EN

Effective June 2015

Power Xpert Solar DC

breaker recombiner

EATON

www.eaton.com

Figure 4. Side view

Chains/cables must be securely attached to hooks, eyes, and

shackles, and the spanner/spreader . Prior to lifting, check the

security of the rigging assembly . Use the crane to bring the

assembly taut without raising the Recombiner from the floor .

Check the security of the rigging again . Make any necessary

adjustments before moving the equipment .

Slowly lift equipment to the minimum height from the floor required

to safely relocate it . Move the equipment to approximately 2 inches

above its resting place . Safely make a visual inspection of the

rigging . If necessary, return the Recombiner to its original resting

place to make any modifications necessary to the rigging .

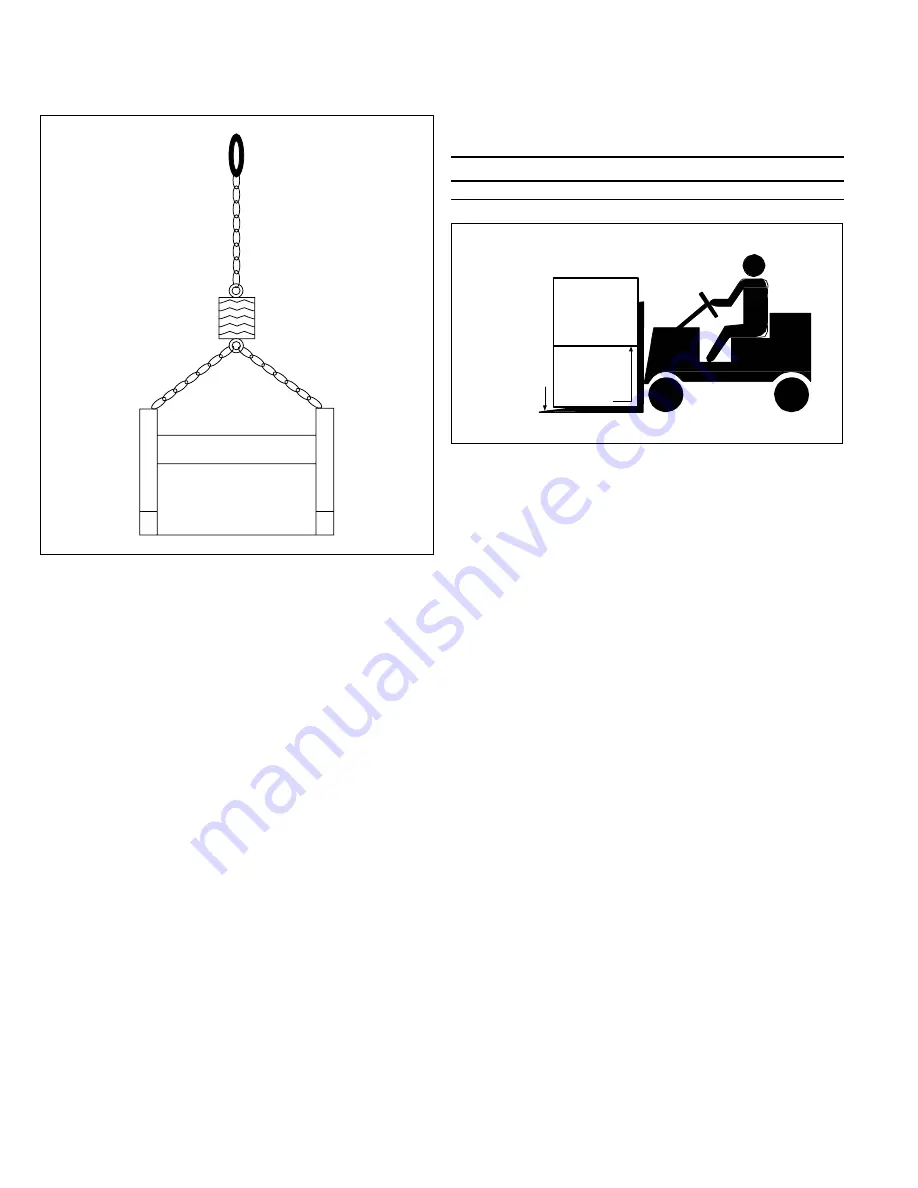

Forklifts

A forklift may be used for handling Recombiners . Only personnel

trained for that equipment should operate forklifts .

Be sure that the ground surface is solid and follow all safety

recommendations for operating the forklift . Be aware of wet or

slick floors and surfaces, which can affect stopping and turning .

Check labeling on the Recombiner packaging material for

additional information .

Verify that the forklift load and lifting ratings are within safe limits for

the weight of the Recombiner being lifted .

Do not lift Recombiner from the front . Damage to components, such

as breakers and metering, can result .

WARNING

RECOMBINER IS TOP-HEAVY. USE CARE IN HANDLING.

Figure 5. Forklift

otee:

N

Always use caution when moving Recombiners, which are

top-heavy equipment .

The forks or blades of the forklift must run through the entire

Recombiner shipping length and be extended to the outermost

sides of the wooden shipping skids (see

Figure 5

) .

Secure the Recombiner with a safety strap, belt, or leash approved

for this purpose . Take care in positioning the strap to ensure stability

of the equipment and confirm that it is not in an area that will

damage components .

Slowly lift equipment to the minimum height from the floor required

to safely relocate it .

Rollers

Rollers should only be used on solid and flat surfaces, such as a

finished floor . Only use rollers that are suitable for this purpose .

Storage

Recombiners, which cannot be immediately installed and energized,

should be stored in an indoor dry, clean, and heated environment .

Do not store in areas where conditions such as dampness, changes

in temperature, cement dust, or a corrosive atmosphere are present .

Should the storage area be prone to moisture condensation, take

precaution by making sure that the Recombiner is covered and

install temporary heating equipment . Approximately 250 watts per

vertical section are required for average conditions .

Recombiners should be placed on solid, level surfaces for storage .

Recombiner sections must remain in an upright position at all times .

Laying Recombiner sections on their back or side can result in

permanent damage to components and the Recombiner structure .

Outdoor Recombiners are not weather resistant until completely

and properly installed and energized . Additionally, using temporary

heating as described above should keep an un-energized outdoor

Recombiner dry internally .

Recombiner

Secure

Recombiner

to forklif t

with safety

strap here

Forks

under entire

Recombiner