14

REAR TERMINAL DESCRIPTION CONTINUED

MODULAR COMMUNICATION JACK

The modular phone jack is an alternate connection to the RS-

485 communications port. Pin 2 is positive and is the same

as terminal 21. Pin 3 is negative and is the same as terminal

22. Pins 1 and 4 are connected to DC Common and should

be used for any shield connections.

Note: This jack is intended only for connection to Ambassa-

dor and other RS-485 communication networks. It

should not be connected to any telephone sys-

tem - damage or hazard may result.

TERMINAL BLOCKS

Connections to the Ambassador are made through deplug-

able, screw terminal blocks to allow for ease of wiring and

removal of the counter. The terminals can accommodate

stranded, solid or fused wire (preferred) from 14 to 22 gauge.

To remove the terminal block, remove AC power and pry

gently underneath each end of the terminal block with small

screwdriver. Press straight on to re-install.

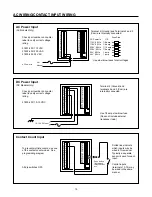

GENERAL WIRING PRACTICES

1. Disconnect all power before wiring terminals. A safety

hazard exists if this precaution is not observed.

Treat all control and count inputs as hazardous

since they may carry line voltage.

2. Use shielded cables for count signals, control input and

communications signals. Connect shield to common (ter-

minal 2, 3 or 4) of counter to terminate properly.

3. Keep all signal lines as short as possible.

4. Do NOT bundle or route signal lines with power or

machine control wiring. Use separate conduit for power

and signal wires.

5. Provide "clean" power to the counter. In severe cases,

power may have to be filtered or a separate power source

used. Do not use the same power source that is supplying

the loads.

6. Use 18 ga. minimum (0.97mm

2

, 600V) and 14 ga. maxi-

mum (2.1mm

2

, 600V) wire for AC power wiring.

7. See page 15 for correct fuse to be used in the power input

wiring.

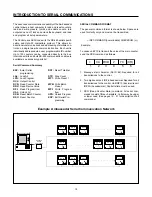

DIP SWITCH FUNCTIONS

Switch 1:

Input A sink/source

Off: input A requires a current sinking input signal.

On: input A requires a current sourcing input signal.

Switch 2:

Input B sink/source

Off: input B requires a current sinking input signal.

On: input B requires a current sourcing input signal.

Switch 3:

Input A threshold level

Off: high threshold level — use with DC sensors.

On: low threshold level — use with mag pickups. Turn

switch 1 on.

Switch 4:

Input B threshold level

Off: high threshold level — use with dc sensors.

On: low threshold level — use with mag pickups. Turn

switch 2 on.

Dip switches may be set through an opening on the bottom

of the unit. It is located towards the rear of the control.

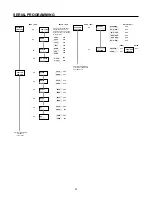

PANEL MOUNTING

The panel mounting kit includes:

(1) mounting gasket, (2) mounting clips and (4) screws.

Refer to the dimension diagram on page 28 for a drawing of

the correct installation of these parts.

The mounting gasket is coated on one side with a contact

adhesive and a paper backing. Care should be taken during

the gasket installation that the gasket be correctly positioned

on the panel at the first attempt. Attempting to re-position the

gasket once the adhesive has come in contact with the panel

is likely to deform or tear the gasket. This may result in an

improper seal. For best results, follow these directions:

1.

Stand the Ambassador counter on a desk or table with

its display down, screw terminals up.

2.

Remove and discard the center square of the gasket at

the scribe marks in the gasket and paper backing. Do not

remove the backing from the remaining outer rim.

3.

Slide the gasket down the unit until it is in position at the

rear of the unit's front bezel. The paper backing side

should be up.

4.

Insert the tip of a knife between the paper and the gasket

and, while holding the gasket down to the unit with the

knife, peel off the paper backing.

5.

Slide the unit through the panel cutout until the gasket

firmly adheres to the panel.

6.

Install the mounting clips and screws as shown in the

diagram 28. Do not overtighten the mounting screws.

The screws should be tight enough to firmly hold the unit

in place, but not so tight as to squeeze the gasket out

from behind the front bezel.

7.

A switch shall be included in the building installation:

• It shall be in close proximity to the equipment and

within easy reach of the operator.

• It shall be marked as the disconnecting device for the

equipment.

• Switches and circuit breakers in Europe must comply

with IEC 947.