Communications

Communicating to a PLC or Controller

You can communicate to a PLC or controller via:

•

A serial connection (COM2, RS232)

•

An optional interface card

•

An Ethernet connection (refer to the

Data

Transfer/Software Download

topic on the

following page for more information about

setting up an Ethernet connection)

Connecting to the Serial Port (COM1)

For convenience COM1 has been pre-configured

with an Elo touchscreen driver to easily connect

Cutler-Hammer touchscreen-displays to your

PanelMate ePro.

The driver is configured to use a mouse and the

touchscreen at the same time.

CAUTION

Your PanelMate ePro unit is not equipped with

isolated serial ports. Ensure that there is no

ground potential difference between your

communication equipment and your

PanelMate ePro unit. If there is a ground

potential difference, your communication

equipment will need to be isolated.

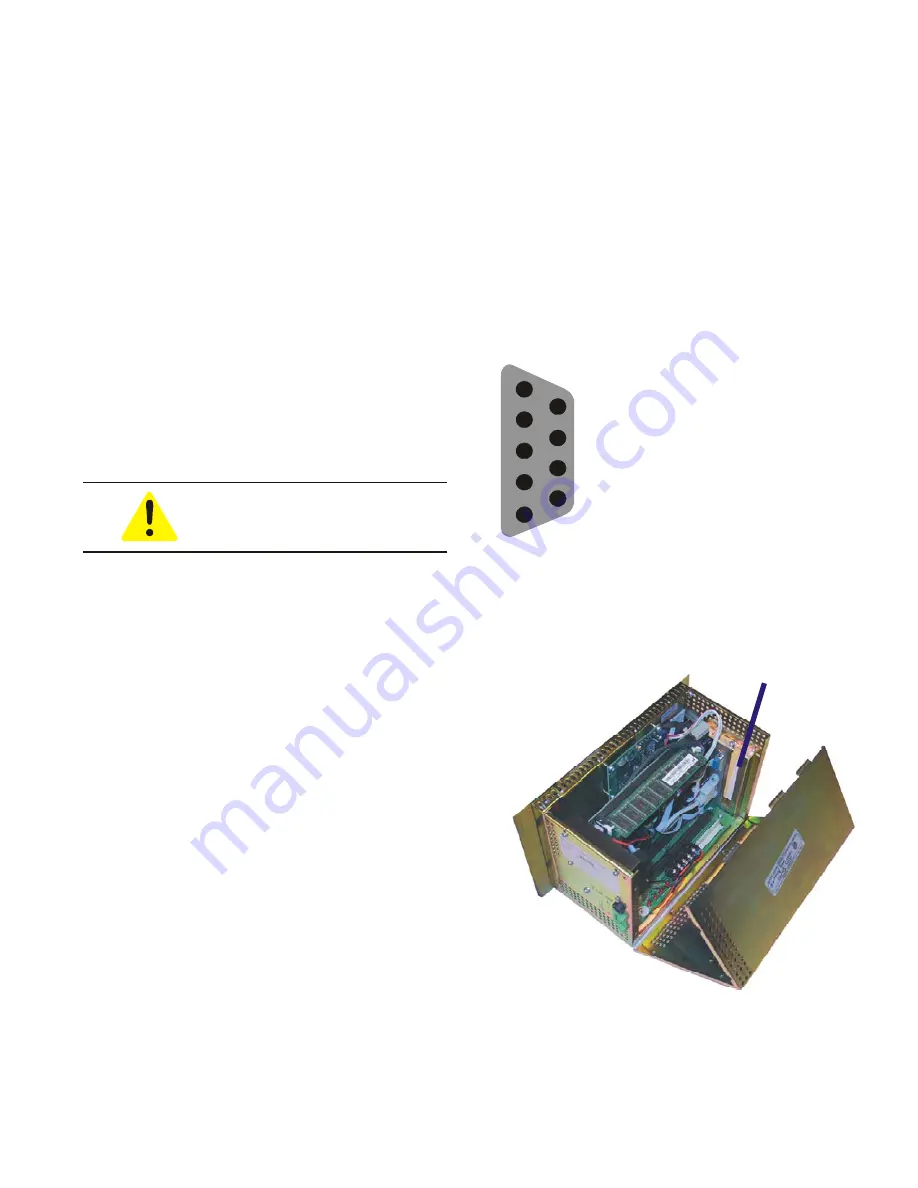

Installing an Optional Interface Card

To install optional interface cards in your

PanelMate ePro unit, complete the following

steps:

1) Disconnect power from your PanelMate ePro

unit.

2) Use a Phillips screwdriver to unscrew the six

screws located on the back of your

PanelMate ePro unit and remove the back

cover.

3) Use a Phillips screwdriver to remove the

screw that secures the slot cover and remove

the slot cover.

4) Place the interface card in the slot and secure

the interface card with the screw from the slot

cover.

5) Reassemble your PanelMate ePro unit and

tighten the six screws located on the back of

the unit.

Connecting to the Serial Port (COM2)

The external serial port may be used for

communications with a PLC or controller.

If you need local printing of alarms and

messages, selection of a serial printer must be

done with the Configuration Software. Refer to

the Configuration Software Online Help and in the

PanelMate Configuration Editor User's Manual for

more information.

COM1 & COM2 Pinouts

Pin Description

2

RS232 Receive Data (Input)

3

RS232 Transmit Data (Output)

5

Signal Ground

7

RS232 Request to Send

(Output)

8

RS232 Clear to Send (Input)

1

2

3

6

7

8

9

4

5

Optional Interface

Card Slot