Step 8 - Tighten cartridge to fuse cartridge holder.

1. Tighten fuse contact flare end against fuse cartridge

holder using 50 to 70 in-lbs. torque.

2. Replace end plug on the other end of fuse cartridge

and tighten to 50 to 70 in-lbs. torque.

3. Remove end plug and ensure that petals of tulip tip

have spread uniformly.

4. Replace end plugs, applying 50 to 70 in-lbs. torque to

both connections.

Step 9 - Install fuse holder.

Use a hotstick to perform the following steps.

1. Pull pressure relief valve, holding it open until hissing

stops, and then for another five seconds.

2. Attach end of fuseholder assembly to hotstick and

insert holder assembly firmly into Bay-O-Net housing.

3. Twist locking handle so that latch engages Bay-O-Net

housing’s shoulder, and steel washer seats tightly on

end of tube of Bay-O-Net holder assembly.

Internal cartridge fuse

Internal cartridge fuses are “weak link” expulsion-type fuses

used to protect transformers and distribution systems.

Internal cartridge fuse assemblies are mounted inside

the transformer tank and are compatible for use in many

insulating liquids. See fuse manufacturer’s product literature

for maximum interrupting ratings.

Internal cartridge fuse replacement

1. Verify that tank is grounded. De-energize transformer

from a remote upstream source. Ground all bushings

and terminals.

2. Remove tank cover as outlined in

Tank Cover Removal

and Installation

section of this manual.

3. Locate cartridge fuse assembly (see Figure 15) on back

tank wall.

4. Carefully remove all nuts that attach wire leads to fuse,

making sure not to drop nuts into the transformer tank.

Note position of all nuts, flat washers, spring washers,

etc., so that they can be reinstalled in the same

locations.

5. Replace fuses as required. Reconnect leads and re-

install washers and nuts in original locations.

6. Re-install cover as outlined in

Tank Cover Removal

and

Installation section of this manual.

Figure 14. Insert replacement fuse link.

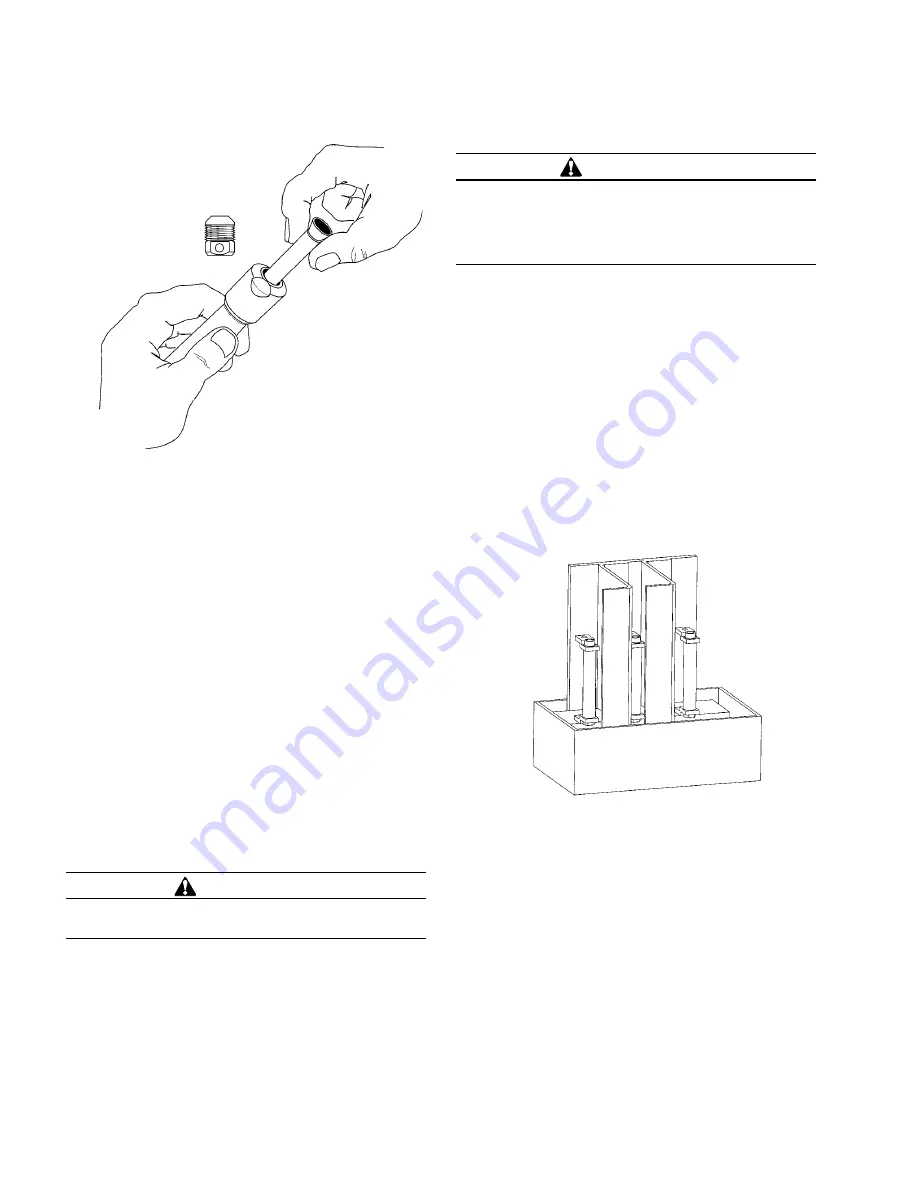

Figure 15. Cartridge fuse assembly.

CAUTION

Visually inspect entire fuseholder assembly to ensure it

is installed properly.

WARNING

Hazardous voltage. Can cause severe injury, death, or

damage to equipment. Turn off power to transformer

before servicing internal cartridge fuses. Ground

transformer following industry accepted safe grounding

practices.

10

Three-phase pad-mounted compartmental type installation and maintenance instructions

MN202001EN August 2015