UNDERSTANDING UPS OPERATION

EATON

Powerware

®

9395 UPS (650–825 kVA) Installation and Operation Manual

S

164201725 Rev 2

www.powerware.com

6−27

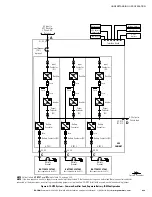

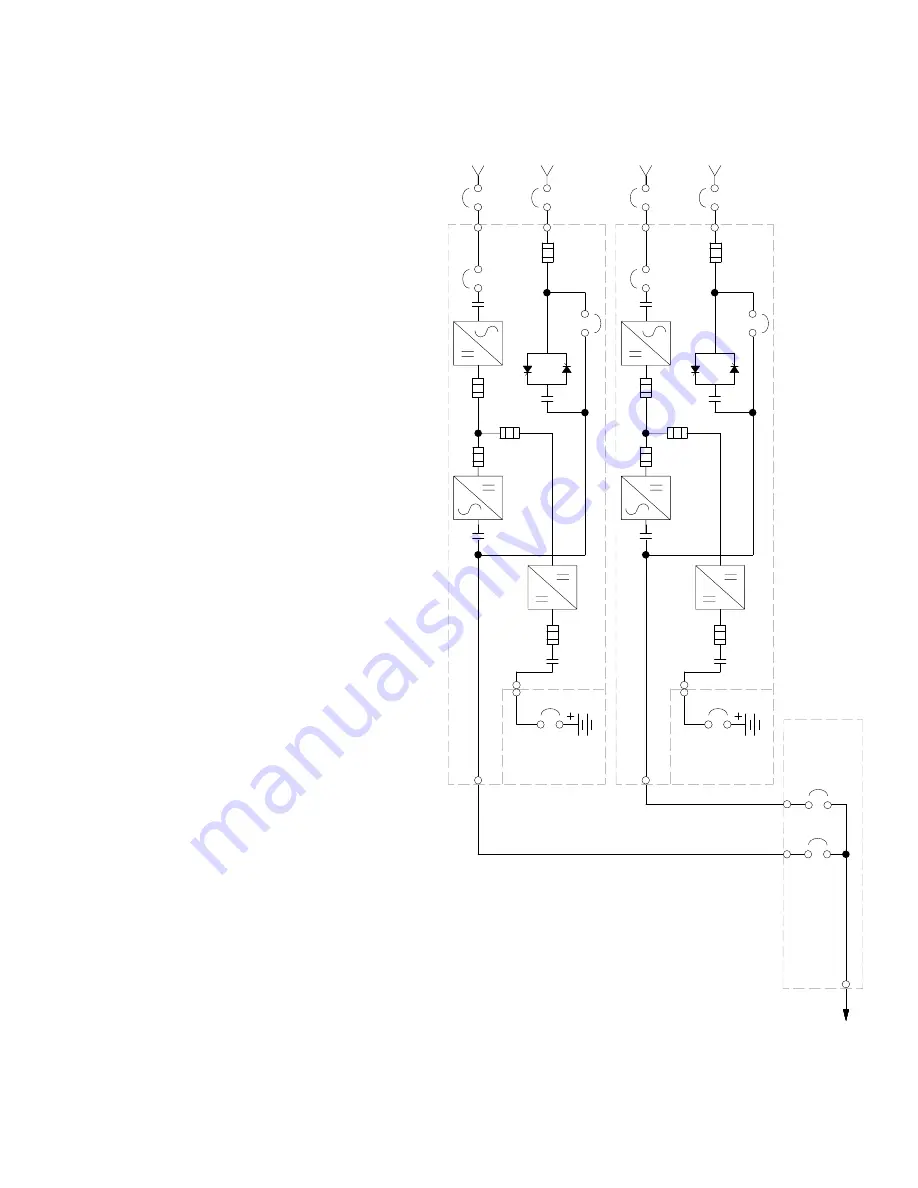

Battery Breaker

Battery

Converter

Inverter

K3

Fuse

Rectifier

K1

K2

Fuse

Fuse

Fuse

E6

E7

E8

E12

K5

Static

Switch

Fuse

CB4

E1

E2

E3

CB1

(optional)

UPS 1

A

B

TIE

CABINET

(Optional)

E

AC Output to

Critical Load

E4. E5

BATTERY SYSTEM

MOB 1

MOB 2

(Not supplied

with the UPS)

C

E9,

E10,

E11,

E12

D

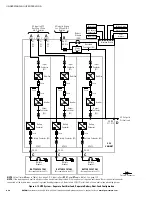

Battery Breaker

Battery

Converter

Inverter

K3

Fuse

Rectifier

K1

K2

Fuse

Fuse

Fuse

E6

E7

E8

E12

K5

Static

Switch

Fuse

CB4

E1

E2

E3

CB1

(optional)

UPS 2

A

B

E4. E5

BATTERY SYSTEM

(Not supplied

with the UPS)

C

E9,

E10,

E11,

E12

D

*

*

*

*

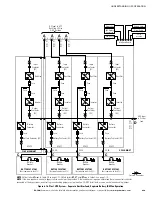

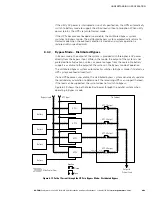

NOTE

This oneline does not show each UPM in the UPSs, but represents each UPS in the distributed bypass system. The internal

structure of each UPS is shown Figure 6-5 through Figure 6-8 starting on page 6−8.

NOTE

If the load requires a neutral, a bypass source neutral must be provided. If the load does not require a neutral and there is no neutral

conductor connected at the bypass input, a neutral to ground bonding jumper must be installed. DO NOT install both a source neutral and a bonding jumper.

A

– AC Input to UPS Rectifier

B

– AC Input to Bypass

C

– DC Input from Battery

D

– UPS AC Output to Tie Cabinet

E

– Output to Critical Load

*

– Overcurrent Protection provided by customer

*

Figure 6-21. Typical Distributed Bypass System (1+1 and 2+0 Configurations)