Operator's Manual

Rolling String Trimmer 600050V, 600050B

Check for parts online at

www.getearthquake.com

or call 800-345-6007 M-F 8-5

5

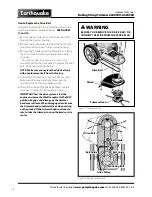

A: Warning!

B: Read Owner's Manual Before Operating Machine

C: Do Not Operate While Others Are Around

D: Remove Objects that Could Be Thrown By This Machine.

E: Never Operate Machine Up and Down Slopes, ALWAYS

Operate Trimmer Across Slopes

F: Be Aware of Moving and Rotating Parts

G: Wear Ear and Eye Protection At All Times

H: Do Not Service or Adjust Moving Parts Unless Engine is

Stopped and Spark Plug Wire is Disconnected.

I: Look Behind and Around you Before and While Moving

Backwards.

J: Toxic Fumes—Do Not Operate in Unventilated Areas

K: Hot Surfaces

L: Fire Hazards.

hazard Symbols and meanings

11. It is advisable to wear protective headgear to

prevent the possibility of being struck by small flying

particles, or being struck by low hanging branches,

twigs, or other objects which may be unnoticed by

the operator.

1. Do not operate the trimmer without proper guard or

other safety protective devices in place.

13. Use this equipment for its intended purpose only.

14. See manufacturer’s instructions for proper operation

and installation of accessories. Only use accessories

approved by the manufacturer.

15. Operate only in daylight or good artificial light.

16. Do not operate product when fatigued or under

the influence of alcohol, drugs or other medication

which can cause drowsiness or affect your ability to

operate this machine safely.

17. Never operate trimmer in wet grass. Always be sure

of your footing; keep a firm hold on the handle and

walk; never run.

18. Before each use, inspect the throttle control lever

and cable. Make sure that the cable is free and that

the lever is not damaged. Also check the cable

linkage running to the carburetor for kinks, loose

fittings, and obstructions. Verify that the control bail

is working properly.

19. Stop the rotating trimmer head when crossing gravel

drives, walks, or roads. Wait for the cutting lines to

stop rotating.

0. Watch for traffic when operating near, or when

crossing roads.

1. Stop the engine (motor) whenever you leave the

equipment, before cleaning, repairing or inspecting

the unit, be sure the trimmer head and all moving

parts have stopped. Let the engine cool, disconnect

the spark plug wire and move it away from the spark

plug.

. If the equipment should start to vibrate abnormally,

stop the engine (motor), disconnect the spark plug

wire and prevent it from touching the spark plug.

Check immediately for cause. Vibration is generally a

warning of trouble.

3. After striking a foreign object, stop the engine (mo-

tor). Remove the wire from the spark plug. Inspect

the trimmer for damage. If damaged, repair before

starting and operating the trimmer.

4. Never leave the trimmer unattended when the

engine is running. Remove the wire from the spark

plug.

5. Regularly inspect the trimmer. Make sure parts are

not bent, damaged or loose.

6. Allow muffler and engine areas to cool before

touching. Never pick up or carry the trimmer while

the engine is running.

7. Prolonged exposure to noise and vibration from

gasoline engine powered equipment should be

avoided. Take intermittent breaks and/or wear ear

protection from engine noise as well as heavy work

gloves to reduce vibration in the hands.

SAfEtY WARning SYmboLS

ContRoL And oPERAting SYmboLS

Pictured below are control and operating symbols on the

unit or in this manual. Before you operate your unit, learn

and understand the purpose for each symbol.

Pictured below are safety and hazard symbols on the unit

or in this manual. Before you operate your unit, learn and

understand the purpose for each symbol.

A

h

g

f

d

C

b

E

L

k

J

i