Operator's Manual

Rolling String Trimmer 600050V, 600050B

Check for parts online at

www.getearthquake.com

or call 800-345-6007 M-F 8-5

19

trouble

Cause

Correction

Engine overheats

Engine cooling system clogged

Clean debris screen and engine

cooling fins

Carburetor out of adjustment

For carburetor adjustment, take the

unit to an authorized service center

Oil level is low

Add oil

Engine will not stop running

Defective throttle control lever or wire Inspect and replace damaged parts

Throttle not adjusted properly

Move throttle to the full OFF position

Poor trimming performance

Trimmer line length is too short

Correct line length is 1.5 inches.

When the line is less than 1/ of this

length, replace the line.

Engine not set at FAST speed

Move engine throttle lever to FAST

position

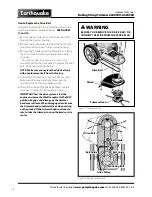

Trimmer vibrates

Set screw for the trimmer head is

loose

Tighten set screw with T-handle

wrench

Trimmer line lengths are substan-

tially different

Adjust trimmer line to approximately

equal lengths

Loose nuts or bolts

Check all bolts and nuts, including

engine bolts

Broken trimmer head

Replace broken part

Trimmer head does not retain line

Trimmer line not properly attached

Follow instructions on decal or in the

Service section of the owner's manual

Broken line retainer

Replace trimmer head assembly

Trimmer line not correct size

Use a 0.155 diameter trimmer line

notE: Please see the engine manual for a full troubleshooting guide for any engine issues.