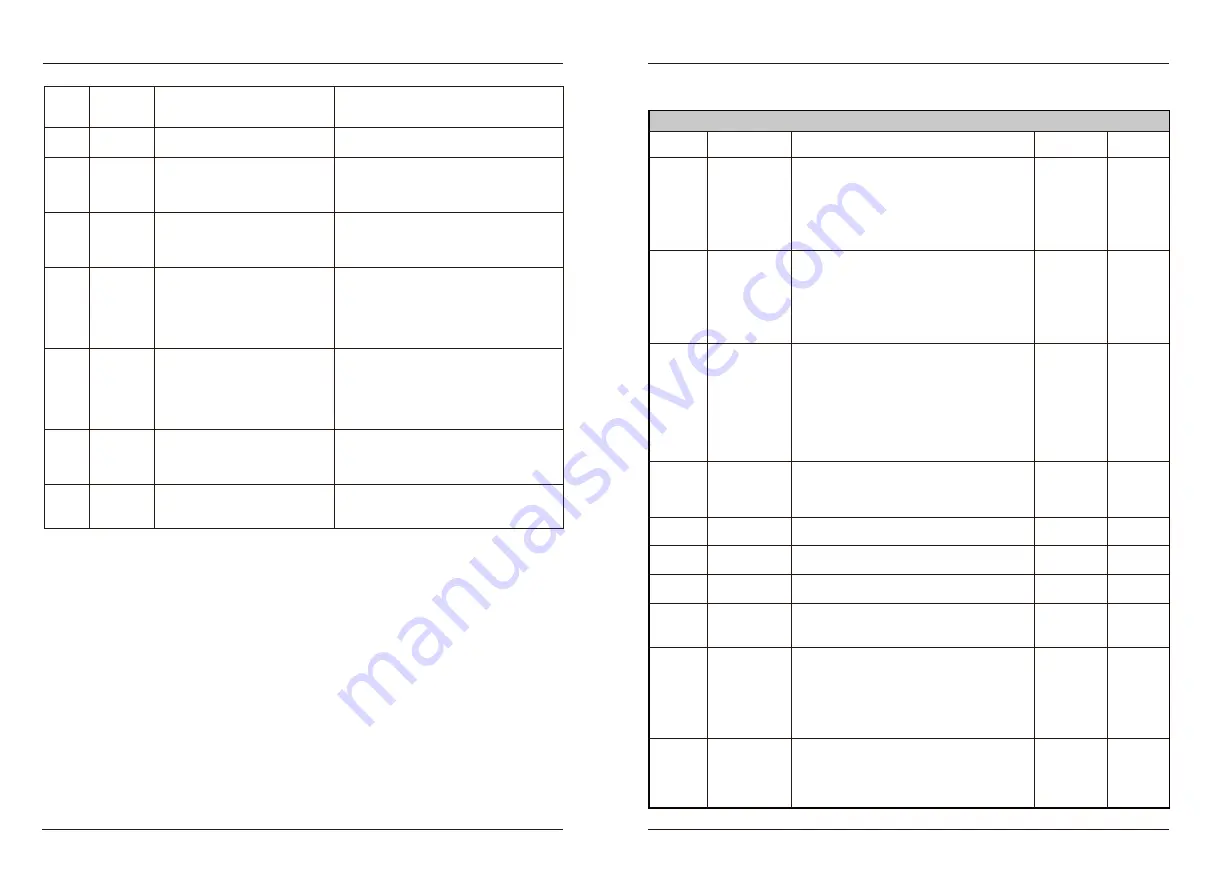

Err27

power-on

time

reached

Err28

1: Accumulative power-ontime

reaches the setting.

1: The AC drive running current

is lower than P9-38

.

1: Clear the record through the parameter

initialization function.

1: Check that the load is disconnected or

the setting of P9-38 and P9-39 is correct.

Err33

Err34

Err29

Err30

Err31

Err32

Load

becoming 0

Motor

overheat

Initial

position

fault

PID

feedback

lost during

running

Pulse-by-

pulse

current

limit fault

Too large

speed

deviation

Motor

over-speed

1: The cabling of the temperature

sensor becomes loose.

2: The motor temperature is too

high.

1: The motor parameters are not

set based on the actual situation.

1: The PID feedback is lower than

the setting of PA-27.

1: The load is too heavy or

lockedrotor occurs on the motor.

2: The AC drive model is of too

small power class.

1: The encoder parameters are set

incorrectly.

2: The motor auto-tuning is not

performed.

3: P9-42 and P9-43 are set

incorrectly.

1: The encoder parameters are set

incorrectly.

2: The motor auto-tuning is not

performed.

3: P9-40 and P9-41 are set

incorrectly

1: Check the temperature sensor cabling

and eliminate the cabling fault.

2: Lower the carrier frequency or adopt

other heat radiation measures.

1: Check the motor para-meters are set

correctly and whether the setting of rated

current is too small.

1: Check the PID feedback signal or set

PA-27 to a proper value.

1: Reduce the load and check the motor and

mechanical condition.

2: Select the AC drive of higher power

class.

1: Set the encoder parameters properly.

2: Perform the motor autotuning.

3: Set F9-69 and F9-70 correctly based on

the actual situation.

1: Set the encoder parameters properly.

2: Perform the motor autotuning.

3: Set P9-40 and P9-41 correctly based on

the actual situation.

7

.

Function Code Table

F u n c t i o n C o d e T a b l e

EC670

F a u l t s a n d s o l u t i o n s

EC670

-

9

-

-

10

-

A0

Basic parameter group

Address

Function

Code

Setting Range

A0

-

00

A0

-

01

A0

-

02

A0

-

04

A0

-

03

A0

-

07

Command source

selection

Preset main

frequency

Motor control

mode

Main frequency

source X

selection

Maximum

frequency

Rotation

direction

1000H

1001H

1002H

1004H

1003H

1007H

0

~

2

0: Voltage/Frequency (V/F)control

(direction LED on)

1: Sensorless flux vector control(SFVC)

(direction LED blinking)

2: Closed-loop vector control(CLVC)

(direction LED fast blinking)

0

~

4

0: Operation panel control (LOC LED on)

1: Terminal control (REM LED on)

2: RS485 Communication control (REM LED

blinking)

3.PV Auto-control (LOC REM on)

4: Terminal switchover (REM LOC LED blinking)

0

~

12

0: Digital setting P0-08

1: AI1 2: AI2 3: AI3

4: Pulse setting(HDI)

5: Communication setting

6: UP/DW setting 7: PID

8: Simple PLC 9: Reserved

10: Reserved 11: Option card

12: Terminal switchover

0.01

~

Maximum output frequency

0.00

~

50.00Hz

The maximum frequency limit allowed by the

frequency converter is also the acceleration

and deceleration time reference.

0000

~

0011

BIT0:0:Same direction 1:Reverse direction

BIT1:0:Reverse enable 1:Reverse disable

Default

0

4

0

50.00Hz

50.00Hz

Acceleration

time1

A0

-

05

1005H

0.1

~

30.0s

3s

0

Parameter Name

1008H

A0

-

08

Carrier

frequency

1

.

0

~

15.0KHz

If the carrier frequency is set higher than

the factory value, it will cause the tempe-

rature rise of the converter radiator to

increase. At this time, the user needs to use

the converter derating, otherwise the conver-

ter will have the danger of overheating alarm.

By type

Deceleration

time1

A0

-

06

1006H

0.1

~

30.0s

2s

1009H

A0

-

09

Restore

default

settings

0

~

65535

0

~

1:No function 2:Reset err mesage

3

~

6:Resv 7:Reset—User data

10:Back up current user parameters

210:Restore user backup parameters

0

~

210