To Assemble (Continued):

10.

Place

59077

Rear Bearing Plate (with

58368

Bearing pressed into place) over shaft and "long" end of line-up pin and press fit in place as

shown in

Drawing 4

.

11.

Install

98463

Snap Ring in groove.

12.

Place

01024

O-Ring into recess in side wall of cylinder.

13.

Install

50659

O-Ring into

59058

Lock Ring. Slide the lock ring assembly over the motor shaft balancer (3/32" and 3/16" orbits only). Apply 1 drop of

pneumatic tool oil and spread between the motor bearing plate and

50659

O-Ring.

14.

Place 1 drop of pneumatic tool oil on

01024

O-Ring.

15.

Secure motor housing in vise, using

57092

Collar or padded jaws. Slide motor assembly into second housing.

Note:

Be certain line-up post enters the

notch in the bottom of the housing and

01024

O-Ring stays seated in cylinder.

16.

Tighten lock ring with

56058

Lock Ring Tool to 23 N•m/200 in.-lbs. Attach weight-mated sanding pad.

Valve and Speed Regulator Assemblies:

1.

Secure housing in vice using

57092

Collar or padded jaws.

2.

Remove inlet bushing,

01468

Spring,

58365

Tip Valve and

01464

Seal from housing. Remove

98927

Pin from housing and lever.

3.

Remove

95697

Snap Ring. Press the speed regulator and valve stem out of the housing. Remove the

01025

O-Rings (2) and

98459

O-Ring.

4.

Place new

01025

O-Rings (2) on the speed regulator and a new

98459

O-Ring on the valve stem. Then place in housing with valve stem. Install new

95967

Snap Ring. Apply a small amount of pneumatic tool oil to valve o-rings.

5.

Place new

01464

Seal in housing. Using tweezers or needle nose pliers, place the tip valve into housing so that the tip valve goes under the valve

stem. Place new

01468

Spring into housing so small end is towards tip valve.

6.

Apply a small amount of #567 Loctite

®

(or equivalent) around the threads of the first inlet bushing and tighten into housing to 23 N•m/200 in. - lbs.

7.

Install Lever on housing with

98927

Pin centered on housing.

Note:

Motor should operate at between 11,000 and 12,000 RPM at 6.2 bar (90 PSIG). RPM should be checked with a tachometer. Before operating,

we recommend that 2-3 drops of Dynabrade Air Lube P/N

95842

(or equivalent) be placed directly into the air inlet with throttle lever depressed. Operate the

machine for approximately 30 seconds before application to workpiece to determine if machine is working properly and safely and to allow lubricating

oils to properly dispense through machine.

Loctite

®

is a registered trademark of the Loctite Corp.

Disc Pad Change:

1.

Insert

50679

Wrench on flats of

57069

Balancer Shaft and twist off sanding pad by hand.

2.

With wrench still in place, hand tighten new pad on tool.

3.

No need to remove shroud or overskirt.

Required Weight of Pads:

3" Models –– Use pad weighing 75g.

3-1/2" Models –– Use pad weighing 80g.

5" Models –– Use pad weighing 100g.

6" Models –– Use pad weighing 130g.

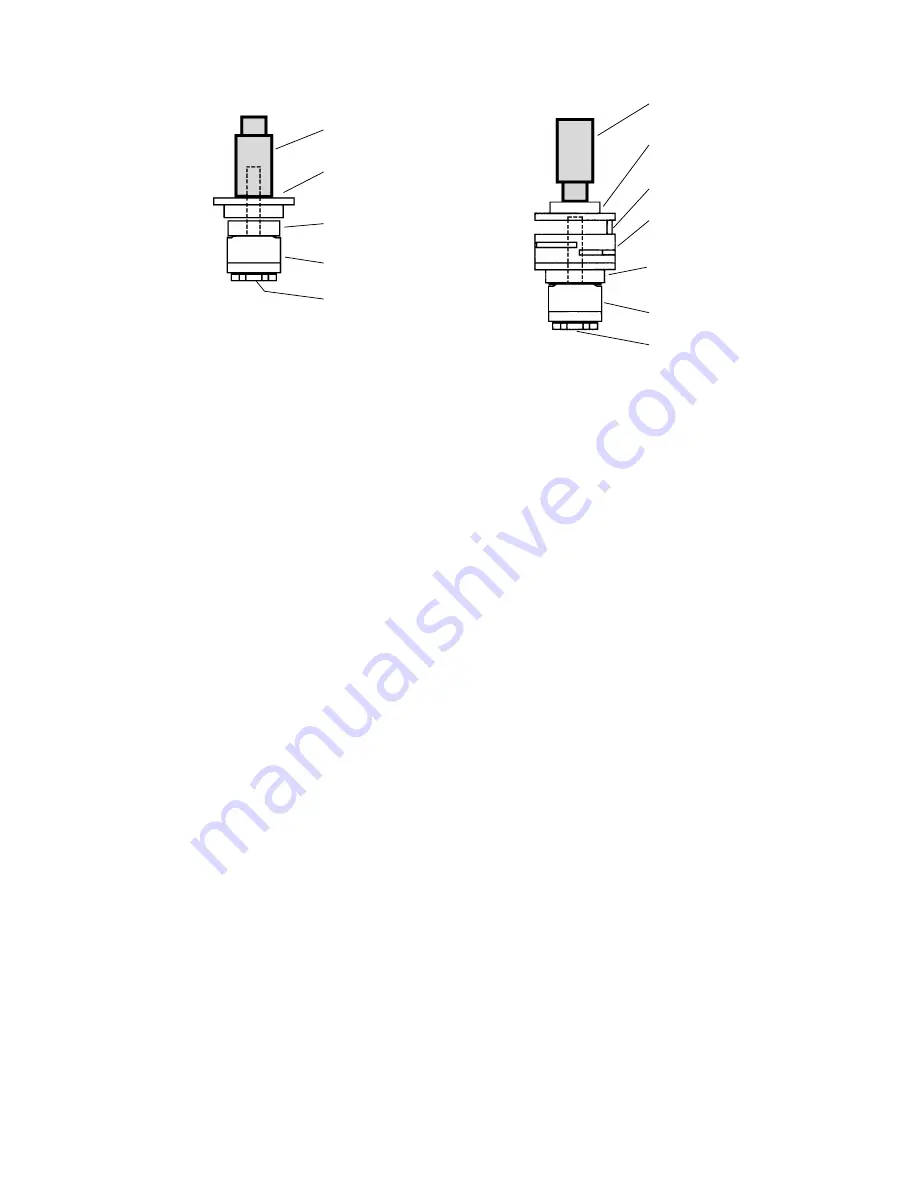

57091

Bearing Press Tool

Balancer Shaft Assembly

Motor Shaft Balancer

58368

Bearing

59076

Front Bearing Plate

Drawing 3

57091

Bearing Press Tool

Balancer Shaft Assembly

Motor Shaft Balancer

59076

Front Bearing Plate

(with

58368

Bearing)

59077

Rear Bearing Plate

(with

58368

Bearing)

59051

Cylinder Assembly

(w/Rotor and Vanes)

Line-Up Pin

Drawing 4

Motor Assembly/Disassembly Instructions - Dynorbital -Spirit

™

8

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade