Page

11

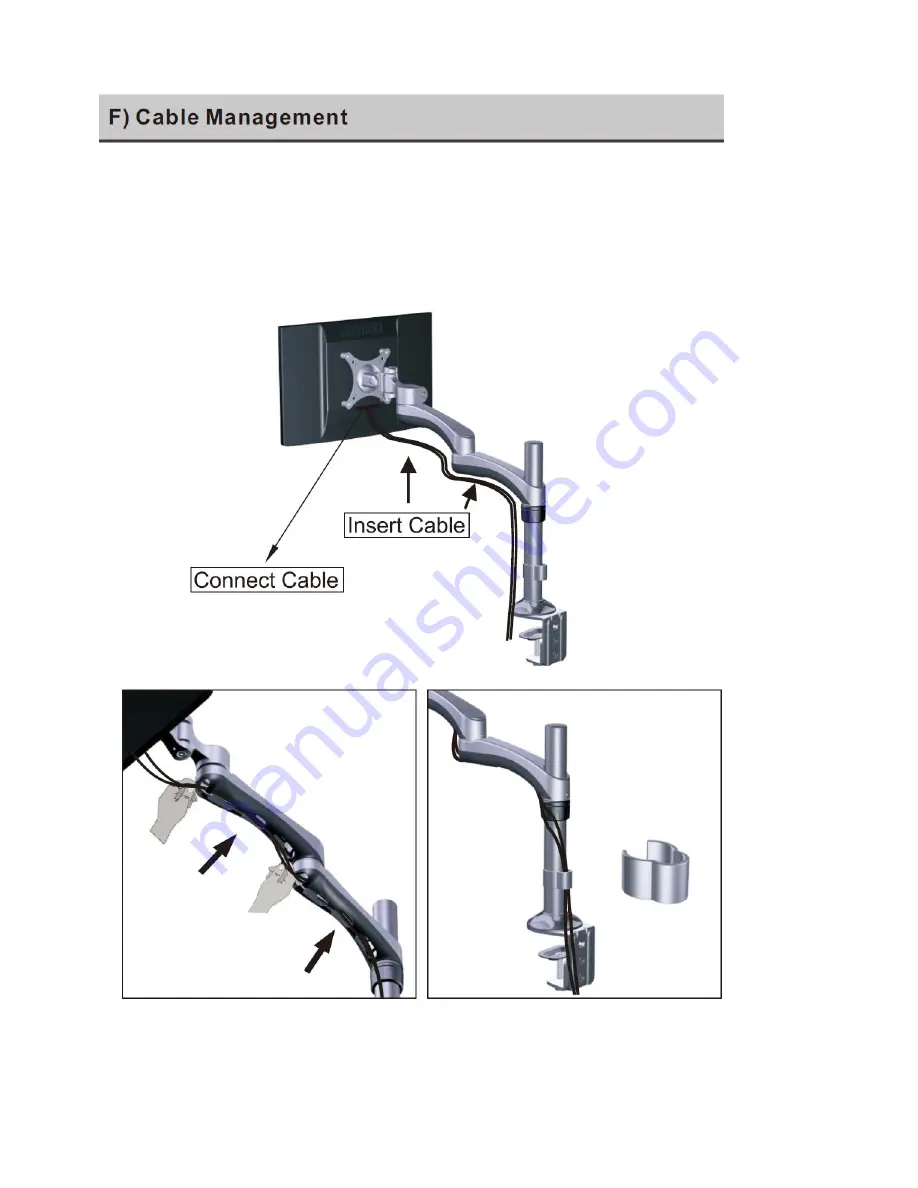

1) Ensure the assembled DE540S mount is fully extended. Be sure to leave enough slack in the

cables to allow for movement of the arms so that they are not stretched or pulled out when the

display is moved.

2) Feed the cables through the cable entry slot on the underside of the arm.

3) Attach the Cable Clip

to secure cables to the pole.