Modbus

®

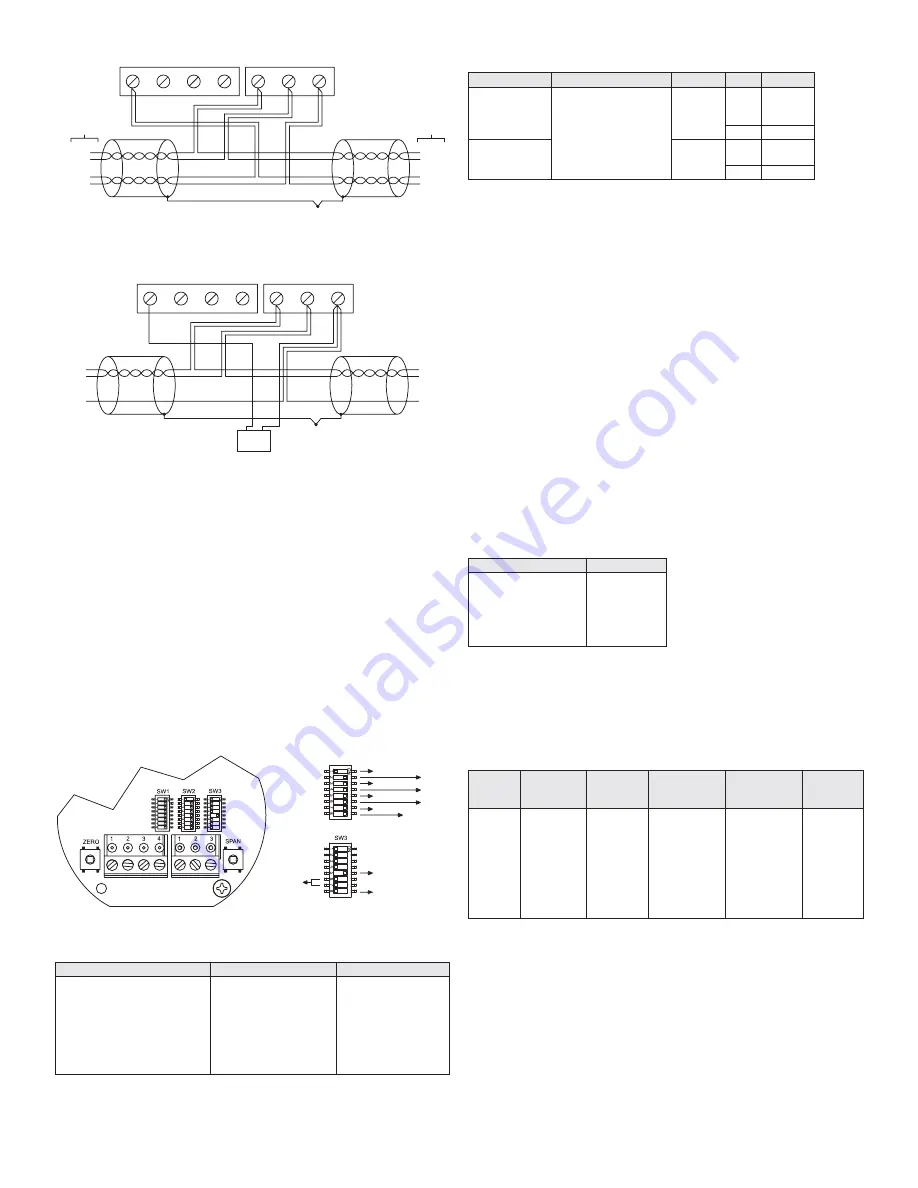

Communication Protocol DIP Switch Settings

Use the middle DIP Switch SW2 to configure the Modbus

®

Communication Protocol

address of the device. The LCD will show the address when the transmitter is powered

on. Valid addresses range from 1 to 247. By default, the device is shipped with the

address 127 (as shown in Figure 10). A valid and unused address should be set before

connecting to an existing network. However, the address can be changed while the

device is operational. If the address is changed, the device will stop responding to the

currently configured address immediately. The device waits 15 seconds after the last

switch change before applying the new address. The device will not function properly

if an invalid address is set. The red LED will periodically blink once indicating an invalid

address. The LCD will display

A Err

when the transmitter is powered on if the address

is invalid. See Appendix V for setting the Modbus

®

Communication Protocol address

of the device. Use the right DIP Switch SW3 to configure other hardware and software

options.

PWR GND IOUT VOUT

TO NEXT

DEVICE

D1(+)

D0(-)

PWR

COM

D1(+)

D0(-)

PWR

COM

TO PREVIOUS

DEVICE

D1(+) D0(-) COM

Figure 7: Common power supply

D1(+)

D0(-)

COM

D1(+)

D0(-)

COM

POWER

SUPPLY

+ -

PWR GND IOUT VOUT D1(+) D0(-) COM

Figure 8: Local power supply

SW2

KEY:

AUTO SERIAL

CONFIGURATION

TERMINATING

RESISTOR

BIAS

RESISTOR

128 - MSB

64

32

16

8

4

2

1 - LSB

Figure 9

Switch

On

Off

1-2 – Display Units Selection

3-4 – Reserved

5 - Intelligent Serial

Configuration

6 – D1(+) Network resistor

7 – D0(-) Network resistor

8 – Terminating resistor

Enabled

511Ω Pull-up to 5V

511Ω Pull-down to GND

120Ω between D0(-) and

D1(+)

Disabled

Pull-up not connected

Pull-down not

connected

Open

Table 5: DIP switch SW3 functions

APPENDIX IV: Programming Via Modbus

®

Communication Protocol

Intelligent Serial Configuration

Intelligent serial configuration enables the device to determine the baud rate, data

size, party, stop bits and even the Modbus

®

Communication Protocol mode directly

from the serial traffic. This allows the Series AVLV to be quickly and easily deployed

after a valid Modbus

®

Communication Protocol address is chosen.

To activate intelligent serial configuration, set a valid Modbus

®

Communication Protocol

address using the left DIP switch SW2, connect the serial bus and power wires, and

then apply power. The device will power up and begin examining the serial bus for

communication. The Red LED will repeatedly flash twice, indicating that intelligent

serial configuration is in progress.

If the device is setup offline or away from the main network, it is necessary to

generate Modbus

®

Communication Protocol traffic in order to configure the serial

communication. Attempting to read input registers is a good method to generate

Modbus

®

Communication Protocol traffic. Note that while serial configuration is in

progress, the device may not respond to requests. The device may require multiple

read requests to complete the serial configuration process.

The intelligent serial configuration process will complete once a message addressed

to the device is received and processed successfully. The serial configuration

parameters are then saved to non-volatile storage and loaded by default each time the

device starts. If the serial configuration of the bus changes, a power cycle of the device

is required to restart the Intelligent Serial Configuration process.

The String data type is read as a stream of ASCII characters, with the first character

sent in the MSB of the first register, and the second character sent in the LSB of the

first register and so on. If the string is shorter than the allotted size, the remaining bytes

will be zero padded.

1 - The serial configuration, no parity with one stop bit is not officially supported by the

Modbus

®

Communication Protocol standard. However, if this configuration is desired,

set switch 5 on DIP switch SW3 to off. The device will configure itself in Modbus

®

RTU

Communication Protocol mode with a data size of 8, no parity, and 1 stop bit. The baud

rate will still be determined automatically.

Modbus

®

Mode Supported Baud Rates Data Size Parity Stop Bits

RTU

9600

19200

38400

57600

76800

115200

8

Even

Odd

None

1

1

None 2

ASCII

7

Even

Odd

1

None 2

Table 6: Supported Modbus

®

communication protocol configurations

Function Name

Function Code

Read Coils

Read Holding Registers

Read Input Registers

Write Single Coil

Write Single Register

Write Multiple Registers

01

03

04

05

06

16

Table 7: Supported Modbus

®

communication protocol functions

Register Description Data Type Value

Range

Multi-

Address

Supported

0001 –

0002

0003 –

0004

Register

Velocity

Flow Area

(ft2)

Velocity

Flow Area

(m2)

Description

Float

Float

Data Type

0.01…999.99

0.00093…92.9

Value

0.01…999.99

0.00093…92.9

Range

Yes

Yes

Multi-

Address

Supported

Table 8: Holding registers