INSTALLATION

Duct Mount:

The transmitter should be mounted away from fans, corners, heating and cooling

coils, and other equipment that will effect the measurement of the air velocity. It

is recommended that the AVLV is mounted 10 duct diameters downstream of any

disturbances and 5 duct diameters upstream of any disturbances, if possible.

1. Mark and drill a 0.750-0.938˝ (20-24 mm) diameter hole into the duct.

2. Insert and center the duct mount flange in the previously drilled hole and mark

location of the three mounting screw holes.

3. Remove the mounting flange and drill or punch the mounting holes in the marked

locations.

4. Fasten the flange to the duct using three #8 x 1/2 pan head sheet metal screws. Do

not over tighten screws.

5. Insert the AVLV probe into the ducts mount flange and set the desired insertion

depth.

6. Note the flow direction and unit alignment as shown on sensor tip and product label,

tighten probe retention set screw on the duct mount flange screw to affix the probe in

place.

Electrical Connection:

The Series AVLV is powered and simultaneously transmits a two-wire 4-20 mA current

output and a three-wire 0-5 VDC or 0-10 VDC voltage output via a removable four

conductor terminal block. The transmitter power supply common is used to reference

the current and voltage outputs so either current, voltage, or current and voltage may

be wired according to the application. The range of the voltage output can be selected

using the on board DIP switches as described in the Analog DIP Switch Settings

section of this manual.

Power Supply

Choose a power supply with a voltage and current rating sufficient to meet the power

specifications under all operating conditions. If the power supply is unregulated, make

sure the output voltage remains within the required voltage range under all power line

conditions. Ripple on the supply should not exceed 100 mV.

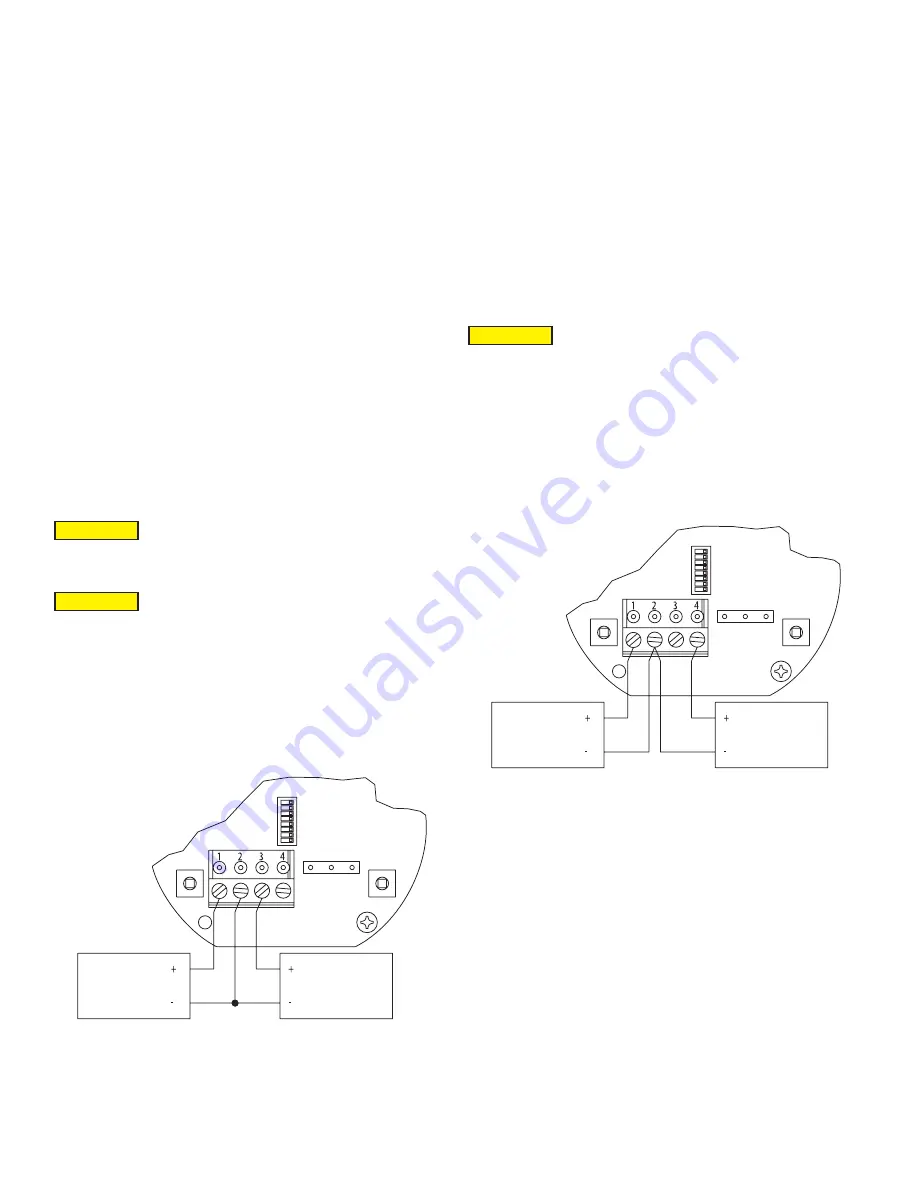

Current Output Operation

The terminal block is removable, and each of the terminals are labeled underneath

the terminal block on the circuit board. As the power supply and outputs share the

same common signal (GND), the outputs may have separate wires but must effectively

join at terminal 2 of the transmitter, as shown in Figure 1. The connections to the

transmitter are made to terminals 1, 2, and 3 (PWR, GND, and IOUT respectively) on

the terminal block as shown in Figure 4.

Figure 1: Current output wiring

Although low loop resistances are recommended, the absolute maximum current loop

load resistance, R

MAX

, is defined by the following the equation:

R

MAX

= (V

PS

– 2.0) / 0.02 where V

PS

is the power supply voltage

For a 24 VDC nominal power supply, this evaluates to R

MAX

= 1100 ohms.

Shielded two wire cable is recommended for current output loop wiring. Ground the

shield at the power supply end only.

The maximum length of connecting wire between the current transmitter and the

receiver is a function of wire size and receiver resistance. That portion of the total

current loop resistance represented by the resistance of the connecting wires

themselves should not exceed 10% of the receiver resistance. For extremely long

runs (over 1,000 ft.), it is desirable to select receivers with higher resistances in order

to keep the size and cost of the connecting leads as low as possible. In installations

where the connecting run is no more than 100 ft, connecting lead wire as small as No.

22 Ga. can be used.

Voltage Output Operation

The terminal block is removable, and each of the terminals are labeled underneath the

terminal block on the circuit board. The voltage output and the power supply must have

separate wire leads that are only joined at terminal 2 of the transmitter, as shown in

Figure 2. Additional error may occur for the voltage output if a single wire is used or if

the wires are joined at the power supply or receiver. The connections to the transmitter

are made to terminals 1, 2, and 4 (PWR, GND, and VOUT respectively) on the terminal

block as shown in Figure 4.

The minimum receiver load is 1 kΩ. The resistance due to the wire should be low

compared to the receiver load resistance. While the voltage at the terminal block

remains unchanged with a 10 mA current flow, resistive losses in the wiring do cause

errors in the voltage delivered to the receiver. For a 1% accurate gauge, the resistance

of the wires should be less than 0.1% of the value of the receiver load resistance. This

will keep the error caused by the current flow below 0.1%.

The output across VOUT and COM will be either 0-5 VDC, 0-10 VDC, or the inverse

depending on the DIP switch setting. See the Analog DIP Switch Settings section for

more information.

Figure 2: Voltage output wiring

SW1

POWER

CURRENT

RECEIVER

SPAN

ZERO

PWR

GN

D

IOUT

VOUT

D1(+

)

D0(-)

CO

M

SW1

POWER

VOLTAGE

RECEIVER

SPAN

ZERO

PWR

GN

D

IOUT

VOUT

D1(+

)

D0(-)

CO

M

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

CAUTION

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

CAUTION