14

English

Switching off:

Release button

4

.

[ESP05-200 T]

Switching on:

Press and release on / off switch

9

. In order to start

spraying material, press and hold button

4

on the

spray gun.

Switching off:

Release button

4

, then press and release on / off

switch

9

.

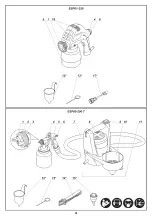

Design features

of the power tool

Sprayed material volume regulation (see fig. 5)

•

Using regulator

6

, you can adjust the volume of

the spayed material in order to get the desired work

result.

• To decrease volume of the sprayed material, rotate

regulator

6

as shown in figure 5 (while spraying

material). Note that the excessive decrease of the

sprayed material volume leads to poorer results of

treatment (insufficient impregnation, too thin a paint

layer, etc.).

• To increase volume of the sprayed material, rotate

regulator

6

as shown in figure 5 (while spraying

material). Note that an excessive increase of the

sprayed material volume results in drips on the

treated surface and overconsumption of the sprayed

material.

Sprayed stream shape regulation (see fig. 6)

[ESP05-200 T]

You can adjust the shape of the sprayed stream by

rotating air cap

2

depending on the direction of the

spray gun's movement (see fig. 6.2-6.4).

•

Loosen coupling nut

3

(see fig. 6.1).

•

Turn air cap

2

to the desired position (see fig. 6.2-6.4).

•

Tighten coupling nut

3

.

Spray gun holder (see fig. 7)

[ESP05-200 T]

The holder

10

is designed to secure the spray gun

during the movement of the power tool or during the

breaks in the work process.

Install the holder

10

as shown on figure 7.1 (the

fixtures on the lugs must click shut). You can install

the holder

10

from different sides of the base unit

11

.

To remove the holder

10

, slightly pull the lugs and

remove the holder as shown on figure 7.2.

Carrying belt (see fig. 7)

[ESP05-200 T]

To facilitate the transportation, as well as to provide

greater portability during the work, use the carrying

belt

14

. Connect the belt

14

to the base unit

11

(see

fig. 7.3). If necessary, adjust the length of the belt

14

so

that make carrying the power tool easier.

Recommendations

on the power tool operation

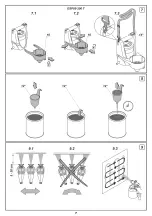

Measurement of sprayed material viscosity (see

fig. 8)

The viscosity of the sprayed material should not

exceed the maximum allowable value (see technical

data table). Thicker materials should be diluted.

Please note! Always use an appropriate solvent,

otherwise the lumps will form that will result in

clogging the power tool.

Measure the viscosity using measuring funnel

12

. The

temperature of the compound should be 20-22°С.

•

Stir the compound thoroughly, immerse measuring

funnel

12

into it, and wait until it fills (see fig. 8).

•

Lift measuring funnel

12

up and let the liquid flow

out. Measure the time of liquid flow out (DIN-s) of

measuring funnel

12

using a stop-watch (from the

start of the flowing-out to jet separation). Approximate

recommended viscosity values for different materials

are given below:

• impregnating agents, varnishes, synthetic resins -

undiluted, 30 DIN-s max.;

• synthetic paints, transparent varnishes - 15-35

DIN-s;

•

acrylic paint - 20-35 DIN-s;

• preservatives, pesticides, oils for wood -

undiluted, 35 DIN-s max.;

•

disinfectant and cleaning agents, polishes - 35

DIN-s;

•

car paint - 18-22 DIN-s.

•

After you are done with the measurements,

thoroughly clean measuring funnel

12

(using an

appropriate solvent).

Surface preparation

•

The treated surface must be cleaned, dried, and

degreased.

• Glossy surfaces should be roughed (with

sandpaper), dust removed, and the surface should be

degreased.

•

The surrounding surfaces that need protection

from precipitation of the "mist" of the sprayed material

should be covered with thick materials (paper, film,

etc.) and lined with adhesive tape, when necessary.

Work sequence (see fig. 9)

•

Prepare the sprayed material and surface as

described above.

• Detach reservoir

5

, fill it with the sprayed material,

and connect it to the spray gun.

•

For model

ESP05-200 T

, adjust the stream shape.

• Switch on the power tool, adjust the volume of the

sprayed material as described above. The "mist" of

spray deflection should be homogeneous and fine.

•

Do a trial treatment on an unnecessary piece

of the same material in order to make sure that the

adjustments are correct.

•

Spray material from a distance of 5-30 cm from the

surface (see fig. 9.1).

•

For model

ESP01-250

- use flexible extension

hose

17

when painting horizontal or sloping

surfaces.

•

For model

ESP05-200 T

- slightly tilt the spray

gun when painting horizontal or sloping surfaces.

Summary of Contents for 742654

Page 1: ......

Page 4: ...4 ...

Page 5: ...5 ...

Page 6: ...6 ...

Page 7: ...7 ...

Page 8: ...8 ...

Page 9: ...9 ...

Page 44: ...44 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 47: ...47 ...

Page 48: ...48 ...

Page 49: ...49 ...

Page 50: ...50 ...

Page 51: ...51 ...

Page 52: ...52 ...

Page 53: ...53 ...

Page 69: ...69 ...

Page 70: ...70 ...

Page 71: ......

Page 72: ...72 ...

Page 73: ...73 ...

Page 74: ...74 ...

Page 75: ...75 ...

Page 76: ......