Instruction Manual ERA REGENERATOR

21

ENGLISH

instruction

manual

ERA REGENERATOR

previous cylce has not been completed correctly.

The salt alarm can be switched off by keeping pressed the

–

key and selecting the

OK

+

OK

+

sequence.

Salt presence in the brine tank (fig.1, D) shall always been

plentiful so as to ensure correct regeneration of softeners.

WARNING:

Please use refined food grade salt that also fits softeners. The

brine tank lid shall always be kept closed so as to avoid dust

or insects contamination; moreover, this prevents that small

objects that might accidentally fall in the tank damage the

equipment or the quality and healthiness of the treated water.

Please use a specific tool to add salt and avoid placing salt

bags on the edge of the brine tank.

The brine tank shall be cleaned every 6 months or, in any

case, each time the tank or the

float are visibly foul (fig. 1, U).

Cleaning shall be carried out by using a wet rug and lukewarm

water.

Do not use detergents or other chemical or abrasive pro-

ducts.

9) RINSE

The ERA regenerator can be configured so as to have a simple

rinse cycle for softeners.

This function might be useful when you want to rinse an ER

cylinder that has not been used for an extended period and

that has to be installed.

1. In order to carry out the rinse cycle, follow the instructions

illustrated in chapter 8 “REGENERATION” up to step 7.

2. Check that the display shows the right model and number

of cylinders to be rinsed (if it is not the right information,

see par. 6.2)

3. Keep pressed the

–

key for 5 seconds until you read the

following message:

4. Press

OK

to confirm.

Once you get to this step, a rinse cycle will start. The rinse

time duration is proposed herein:

RINSE TIME DURATION

Model ER5:

. . . . . . . . . . .

1 min

Model ER8-ER10:

. . . . . . .

2 min

Model ER12:

. . . . . . . . . .

2,5 min

Model ER14:

. . . . . . . . . .

3 min

Model ER16:

. . . . . . . . . .

3,5 min

Model ER18-ER20:

. . . . . .

4 min

If the

OK

button is not pressed, there will be no rinse cycle

and after some seconds the display will go back to the

main screen.

5. Once the rinse cycle is over, please check that there are no

alarm messages on the display.

6. Turn the knobs on the “ERV” valves to “REPLACE”, pull

apart the two gray blocks to unfasten the valves (fig. 4, B),

disconnect the softener by removing the ERV valve(s) from

the cylinder(s).

The softeneres are ready to be used again.

10) MAINTENANCE

The ERA regeneration equipment does not require any

specific maintenance procedure. It monitors salt level

in the brine tank and tells, via the ERA gearcase, when

maintenance interventions are needed

.

After 300 regeneration cycles, the display will show “EJECTOR

MAINTENANCE”;

after 600 regeneration cycles, the display will show “PISTON

MAINTENANCE”.

The two maintenance procedures are illustrated in paragraph

10.2 and 10.3 respectively.

Moroeover, verifying the number of completed regenerations

is possible by pressing the

+

key, as described in chapter

11.

10.1 REGENERATOR DISCONNECTION

Maintenance can be carried out after having disconnected the

ERA gearcase. Instructions are proposed herein.

1. Close the infeed water tap (fig. 1, G)

2. Keep the

–

key pressed for 5 seconds so as to read the

“RINSE” message

3. Press

OK

to confirm

4. Wait for a few seconds and then disconnect the electrical

connector (fig.1, E)

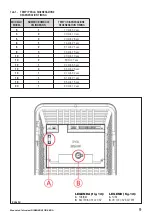

5. Unscrew the fixing screws located under “ERA” (fig. 2, D)

10.2 INSTRUCTIONS FOR EJECTOR CLEANING

1. Disconnect the equipment (see par. 10.1).

2. Turn upside down the gearcase so as to able to see the

internal components (fig. 5).

3. Disconnect the ERV valve pipes (fig. 5, M). Unscrew the

plastic nut used for the outlet part (fig. 5, N).

4. Disconnect the small motor faston connectors (fig. 5, K)

and, by using a wrench, unscrew the coupling (fig. 5, I).

5. Gently pull out the ejector (fig. 5, H).

6. Clean the ejector in running water and check that the ejec-

tor hole is not clogged.

7. Put the ejector back in its housing by pushing it down to

the mechanical stop.

8. Reassemble the equipment by following this same in-

structions backward; make sure you correctly install the

motor faston connectors (fig. 5, K).

10.3 INSTRUCTIONS ON HOW TO CLEAN THE BLOCK

VALVE PISTON

The procedure for cleaning the piston in the block valve is

herein proposed:

1. Disconnect the equipment (see par. 10.1).

2. Unscrew the two screws located at the bottom of the ge-

arcase (fig. 2, D).

3. Turn upside down the gearbox so as to be able to see all

the internal components (fig. 5).

4. Disconnect the 3 block valve pipes (fig. 5, P).

5. Pull out the connector with the electrodes located on top

of the block valve (fig. 5, A).

6. Unscrew the valve coupling (fig. 5, G).

7. Pull out the piston (fig.5, E) without damaging the spring

(fig. 5, F).

8. Clean the piston and the electrods under running water,

then replace the piston gaskets (fig.5, E).

9. Put back in their housing the piston, the spring and the

electrodes, then fasten the coupling to the valve body.

10. Reassemble the equipment by following this same in-

structions backward; make sure you correctly install the

electrode connector and the three block valve pipes, whi-

ch have to be pushed down to the mechanic stop (see

par. 3.3.2).

10.4 FILTER CARTRIDGE REPLACEMENT

Filter cartridge replacement is advisable in order to keep the

RESIN RINSE