16

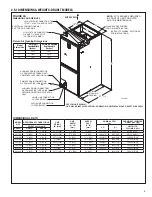

3.2.5 INSTALLATION IN CORROSIVE ENVIRONMENTS

The metal parts of this unit may be subject to rust or deterioration if exposed to a cor-

rosive environment which can shorten its life. In addition to exposure to the exterior of

the cabinet, chemical contaminants inside the building that can be drawn into the unit

from the return air grille and attack structural metal parts, electrical components and the

indoor coil, causing premature failure of the unit. If the unit is to be installed in an area

where contaminants are likely to be a problem, special attention should be given to iso-

late the unit and return grille from contaminants.

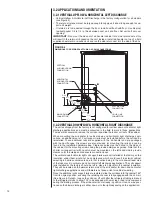

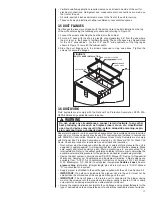

3.2.6 SUPPORTING AIR-HANDLER IN HORIZONTAL APPLICATIONS

The air-handler must be adequately supported underneath if it is installed in the hori-

zontal position to prevent it from sagging in the middle which can cause issues remov-

ing and re-installing the access panels. Position the unit on adequate supports or on

support angles or channels (See Figure 9) before connecting ductwork to the unit. If

an auxiliary overflow pan is required (See Section 3.3), the overflow pan will need to be

adequately supported with the air-handler being supported underneath within the auxilia-

ry overflow pan by angles and/or channels.

3.3 AUXILIARY OVERFLOW PAN

I

n compliance with recognized codes, an auxiliary overflow pan must installed under all

equipment containing evaporator coils that are located in any area of a structure where

damage to the building or building contents may occur as a result of an overflow of the

coil drain pan or a stoppage in the primary condensate drain piping. See Section 6.3 of

this manual for information regarding the recommended auxiliary horizontal overflow pan

(model RXBM) for this air-handler.

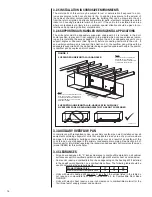

3.4 CLEARANCES

• All units are designed for “0” inches clearance to combustible material on all cabinet

surfaces except for downflow application with higher kW electric heat as noted below.

• Some units require a combustible floor base depending on the heating kW if installed

in the downflow configuration on a combustible surface. The following table should be

used to determine these requirements.

• Units with electric heating kW equal to or less than the values listed in the table do

not require a combustible floor base. See Section 6.5 for Combustible Floor Base

RXHB-XX.

• Units with electric heat require a one inch clearance to combustible material for the

first three feet of supply plenum and ductwork.

Model Cabinet Size

17

21

24

Maximum Model Designation kW

15

18

20

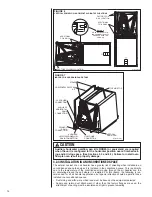

SUPPORTING HORIZONTAL AIR-HANDLERS IN AUXILIARY

OVERFLOW PANS OR AIR-HANDLERS THAT ARE NOT SUSPENDED.

NOTE:

DO NOT BLOCK AIR-HANDLER ACCESS

WITH SUPPORT RODS, ALLOW SPACE

FOR PROPER SERVICE MAINTENANCE

OR REPLACEMENT OF THE COIL AND

BLOWER ASSEMBLY.

NOTE:

HORIZONTAL LEFT ORIENTATION

DEPICTED IN ILLUSTRATION.

HORIZONTAL RIGHT ORIENTATION

IS SIMILAR IN INSTALLATION.

SUSPENDED HORIZONTAL AIR-HANDLER.

AIR FL

OW

ST-A1298-01

FIGURE 9