8

7.6

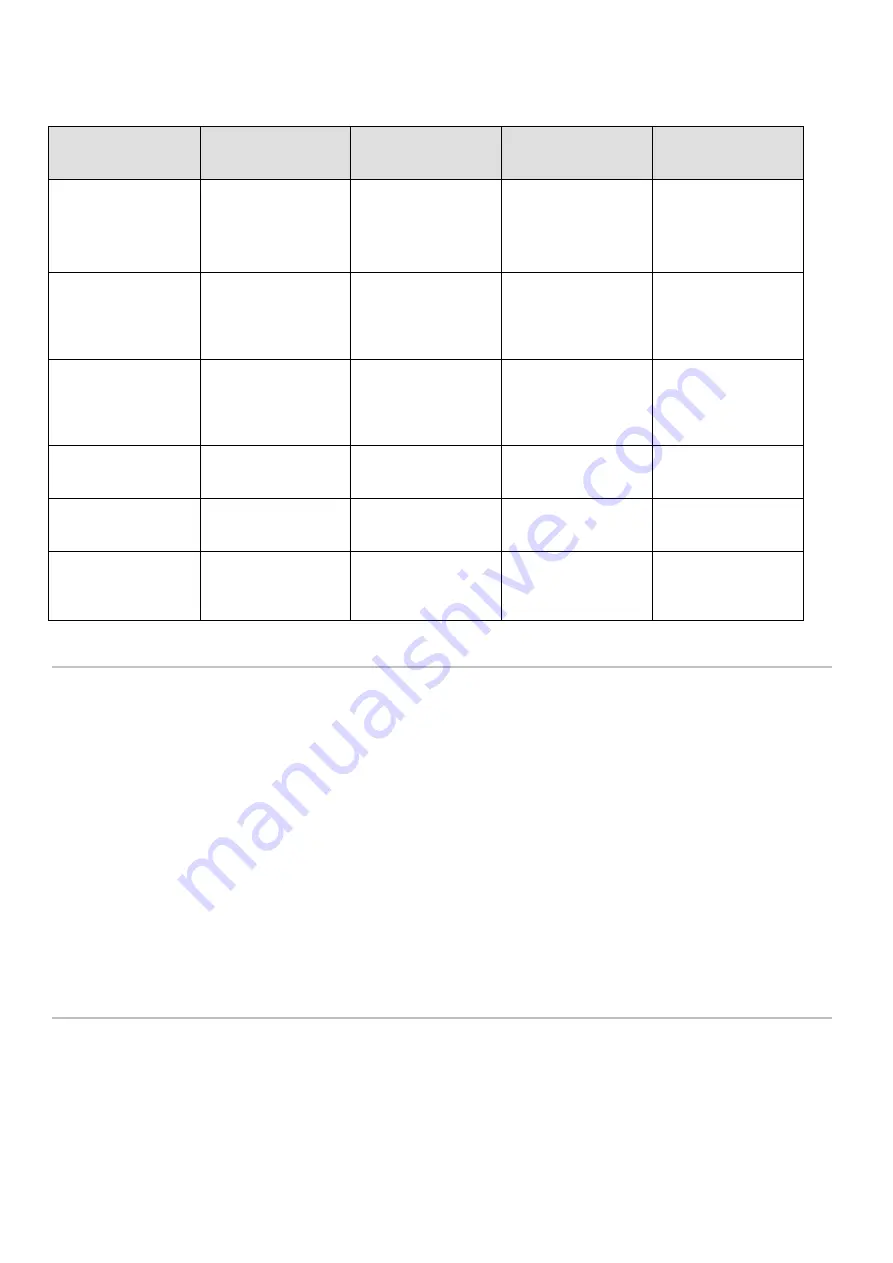

APPROXIMATE CONSUMPTION FOR LRT OILS (3226661) USAGE

Grams per lubrication nozzle in 8 hours operating time

ALUMINIUM

LEADED BRASS

LEADED STEEL

SOFT STEEL

ALLOY STEEL

STAINLESS STEEL

REFRACTORY

AND TITANIUM

ALLOYS

Saw cutting

Turning

Shearing

Cutting off

35-40

30

30

30-60

Boring

Drilling

Milling

Slotting

30-40

30

60

70

Threading

Tapping

Planing

Shaving

60

70

80

90

Threading blind

tapping

60

70

80

90-100

Moulding and

standard drawing

60

70

80-90

90-100

Broaching

Toothing

Bending

70

80

90

100/110

8. MAINTENANCE

The pump has been designed and constructed so as to reduce maintenance to a minimum.

To simplify maintenance it is recommended that the equipment be mounted in an easily reached location

(see paragraph 6.2)

.

Periodically check the tubing connections for leaks. Always maintain the equipment in a clean condition in

order that any leaks will be immediately evident.

When necessary replace the oil filling filter P/N 3130139.

Periodically empty the pressure regulator condensate trap by rotating the small red valve located at its

base.

The machine does not require any special tools for carrying out checks and/or maintenance tasks. It is

recommended that suitable tools and personal protection clothing (gloves) are used in accordance with

current regulation(Safety at Work legislation), and that they are in good condition (according to current

regulation) in order to avoid injury to persons and damage to the machine.

Ensure that electrical, pneumatic and hydraulic supplies are disconnected before undertaking any

maintenance tasks.

9. DISPOSAL

During the maintenance of the machine, or in the event of its being scrapped, do not discard polluting

components in the environment. Refer to local regulations for their correct disposal. At the time of final

disposal of the machine it is necessary to destroy the identification plate and all other documentation.