8.

Coil stop adjusted to allow approximately (0.8 mm)

(1/32”) flapper travel in front of nozzle.

9.

All mechanism components fastened firmly as

required.

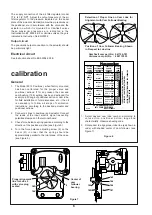

10. Proper nozzle size selected. Number of nozzle

stamped on body of nozzle. The table below

indicates nozzle number for each utilization case.

Pneumatic circuit

In the event of faulty operation of the positioner, where

the cause is not readily apparent, check air system as

follows :

1.

Exert sufficient force on the flapper to cover the

nozzle. Valve stem should travel its full stroke.

2.

If response is other than indicated in the above

steps, push cleanout plunger of metering orifice,

Inspect for plugged nozzle. Check to see if metering

orifice body is properly seated in the relay. If difficulty still

persists, disassemble and clean relay.

Electrical circuit

After checking pneumatic circuit, the electrical circuit

should be checked with an ohmmeter as follows:

1.

Disconnect signal leads from terminal board S/A.

2.

Connect ohmmeter leads to positioner terminal

board leads and check positioner circuit resistance

with nominal resistance indicated on identification

plate. Table of Figure 4 of the Instruction sheet No

ES 50004-000 E shows the nominal resistance of

main circuits.

3.

Disconnect coil lead from positive terminal and

connect to one of the ohmmeter leads. Connect

other ohmmeter lead to negative terminal. Force coil

resistance value should approximate value indicated

in table of Figure 4 of Instruction sheet No

ES 50004-000 E.

4.

If force coil resistance is approximately correct but

positioner circuit resistance is not, repair or replace

terminal board. If force coil resistance is not correct

replace force coil.

5.

Remove ohmmeter lead from negative terminal and

connect it to coil stop screw. Check for short in force

coil.

Replace the coil if ohmmeter indicates a value other

than very high resistance (practically infinite).

Supply

Pressure

150 to

300 mm

(6” to 12”)

80 and

100 mm

(3” and 4”)

25 to

50 mm

(1” to 2”)

psi

m bar

Nozzle Number

Valve size

20

15

25

15

30

15

13

35

13

40

12

45

12

50

12

55

12

60

12

65

11

70

11

75

*

Only on 100 mm (4”) valve size

1400

1700

2100

2500

2800

3100

3500

3800

4200

4500

4800

5200

11

12

12

11

11

11*

11*

On Valves Camflex II

Supply

Pressure

No 3

No 5

No 7

No 9

psi

m bar

Nozzle Number

Actuator size

20

25

30

14

15

15

15

15

15

11

11

15

35

40

45

50

11

11

11

11

11

11

11

11

11

55

60

65

70

75

1400

1700

2100

2500

2800

3100

3500

3800

4200

4500

4800

5200

12

14

11

11

12

14

14

14

14

14

14

14

11

11

12

12

12

12

12

12

12

12

12

12

On Varimax Valves

August 1997