2.

Be sure that the coil and the terminal board are

correct for the input signal characteristics. Refer to

table on page 4 of the instruction sheet No ES

50004-000 E for identification code number of these

items.

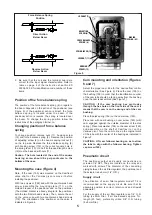

Position of the force balance spring

The position of the force balance spring (8) in regard to

the beam depends on the action of the positioner (see

Figure 5). If the positioner action is direct, the force

balance spring is located under the beam. If the

positioner action is reverse, the spring is located over

the beam. To change the spring position follow the

instructions of the paragraph further on.

Changing position of force balance

spring

To change position, remove nuts (11), hooking screw

(12) and force balance spring (8). Reverse the position

of adjusting screw (6) on the beam keeping locknut (7)

on the top side. Replace the force balance spring (8)

with hooking screw (112) in the correct square hole in

the spring lever (10). On half its threaded length, screw

(12) must be blocked with nuts (11).

Caution : The hole located at the end of the square

hooking screw should be perpendicular to the

bottom of the case.

Mounting the case (Figure 4)

Note : If the cam (155) was mounted on the Camflex II

valve shaft or the Varimax pivot, remove it before

installing the positioner.

With two screws H (152) and with the countersunk head

screw, assemble the mounting plate (171) on the

molded bracket of the positioner and on the positioner

(The molded bracket is already integral to the positioner

with the two fillister-head screws). Then, secure the set

on the valve yoke with two countersunk head screws

(172). The orientation of the positioner on the valve is

indicated in Figure 4.

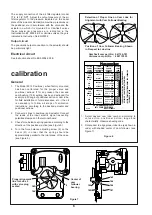

Cam mounting and orientation (Figures

6 and 7)

Select the proper cam lobe for the desired flow control

characteristics. (See Figure 6). Place the cam (155) on

the bushing (159) in order that the identification number

of the cam lobe should be facing away from the bushing

once the cam is assembled (See Figure 7).

CAUTION : If the cam bushing hex protrudes

through the hex hole on the front side of the cam it

means that the cam is on the wrong end of the cam

bushing.

Place the disk spring (156) on the cam screw (160).

Place cam with cam bushing on cam screw (160) (with

cam engaged against the outside diameter of the disk

spring). Place lock washer (158) on the cam screw (160)

and assemble on the shaft of Camflex II or on the

Varimax pivot. Turn the cam to line-up the original mark

of the lobe with the center of the bearing as indicated in

Figure 7.

CAUTION : Lift cam follower bearing so as to allow

the lobe to align with the follower bearing. Tighten

cap screw (160).

Pneumatic circuit

The positioner output and supply connections are

screwed 1/4” NPT. They are located on the relay and

marked with arrows. The diameter of the connecting

piping between the air filter-regulator, the positioner and

the actuator is 4 x 6 mm (1/4” O.D.).

Supply circuit

The utilization of an air filter-regulator model 77-4 is

recommended on the supply circuit. Be sure that its

assembly position is correct. (drain-cock and dripwell

downward).

For the supply of the air filter-regulator use 1/4” O.D.

tubing (4 x 6 mm Dia.). If air line exceeds approx. 7 m.

length (23 feet), preferably utilize 3/8” O.D. tubing

(6 x 8 mm Dia.).

5

LOCKNUT (7)

ADJUSTING

SCREW (6)

FORCE BALANCE

SPRING (8)

SPRING LEVER (10)

LOCKNUT (11)

HOOKING

SCREW (12)

BIASING

SPRING (52)

Figure 5

Force Balance Spring

Position

Direct Action

Below Beam

Reverse Action

Below Beam