14

OM-DH(T) DOMESTIC & (CE) INTERNATIONAL

2. Replace with new pressure gauge ensuring that an adequate sealing

compound is used.

3. Once the pressure gauge has been replaced, the kettle jacket will require

venting.

OM-SM-DH-CE

17

OM/SM-DH-CE

Recommended spacings are shown in this drawing.

DH-20 shown

g) Ensure that there is an adequate spark at

the sparking electrode and that the burners

light smoothly and without delay.

h) As the burners ignite, ensure that the

sparking sequence stops and that the

burners remain lit.

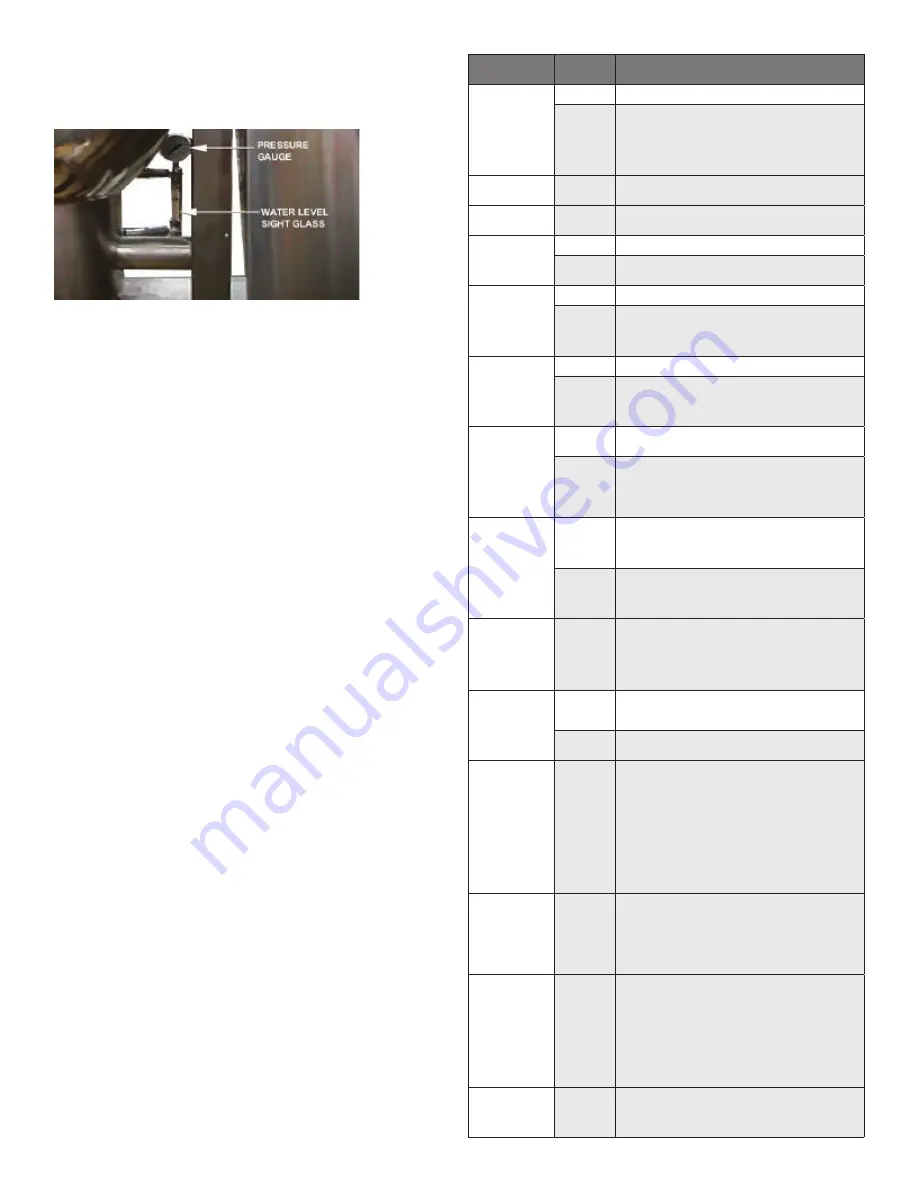

3.17

Removal of Pressure Gauge (Turn the

gas and electricity mains off)

a) Using the correctly sized spanner remove

the pressure gauge from top of the sight

glass.

b) Replace with new pressure gauge ensuring

that an adequate sealing compound is used.

c) Once the pressure gauge has been

replaced, the kettle jacket will require

venting. (Para 3.2)

3.18

Removal of Sight Glass (Turn the gas

and electricity mains off)

a) Remove sight glass protection bars.

b) Undo top and bottom compression fittings.

c) Allow the water in the sight glass to drain.

d) Remove the sight glass.

e) Replace in reverse order.

15 mm

13 mm

REMOVAL OF SIGHT GLASS (TURN THE GAS & ELECTRICITY MAINS OFF)

1. Remove sight glass protection bars.

2. Undo top and bottom compression fittings.

3. Allow the water in the sight glass to drain.

4. Remove the sight glass.

5. Replace in reverse order.

6. Once the sight glass has been replaced, the lost jacket water requires

replacement.

REMOVAL OF STEAM SAFETY VALVE (TURN THE GAS & ELECTRICITY MAINS OFF)

1. Remove the elbow from the safety valve.

2. Remove the steam safety valve from kettle jacket pipework.

3. Replace in reverse order.

4. Ensure an adequate sealing compound is used to seal the safety valve.

5. Once the steam safety valve has been replaced the jacket will need to be

vented. See detailed Instructions pertaining to Steam Safety Valve installation

and operation.

REMOVAL OF FILLING VALVE (TURN THE GAS & ELECTRICITY MAINS OFF)

1. Remove filling valve from kettle jacket pipework.

2. Replace in reverse order.

3. Ensure adequate sealing compound is used to seal the valve.

4. Once the fill valve has been replaced the jacket will need to be vented.

REPLACEMENT PARTS

To order parts, contact your Authorized Service Agent. Supply the model

designation, serial number, part description, part number, quantity, and when

applicable, voltage and phase.

CONTACT US

If you have questions pertaining to the content in this manual, contact Unified

Brands at 888-994-7636.

TROUBLESHOOTING

This unit is designed to operate smoothly and efficiently if properly maintained.

However, the following is a list of checks to make in the event of a problem.

Wiring diagrams are found at the end of this manual. When in doubt, turn unit

off and call for service at 888-994-7636. If an item on the check list is marked

with (X), it means that the work should be done by an Authorized Service Agent.

SYMPTOM

WHO

WHAT TO CHECK

X indicates items which must be performed by authorized technician.

Display not lit

(Advanced only)

User

a. That power supply is on.

Auth Service

Rep Only

b. Fuses, accessible by removing caps on the side of the control box.

c. For loose or broken wires. X

d. Temperature controller functioning, by listening for a click

when the switch opens or closes and verifying LEDs on back

of board. X

e. Contactor functioning. X

PROB in display

(Advanced only)

Auth Service

Rep Only

a. For loose or broken wires or damaged/failed RTD probe. X

b. PCB board malfunction/failure

HI in display

(Advanced only)

Auth Service

Rep Only

a. For loose or broken wires or damaged/failed RTD probe. X

b. PCB board malfunction/failure

Kettle is hard to tilt

User

a. Gears for foreign materials, and lubrication.

Auth Service

Rep Only

b. Gears for alignment. X

c. Worm gears or broken gears. X

Kettle continues

heating

after it reaches the

desired temperature

User

a. Temperature Controller dial setting.

Auth Service

Rep Only

b. Temperature Controller calibration and offset.X

c. Temperature Controller operation. The Temperature Controller

should click when the dial is rotated to settings above and

below the temperature of the kettle.X

Kettle stops heating

before it reaches the

desired temperature

User

a. Temperature Controller dial setting.

Auth Service

Rep Only

b. Temperature Controller calibration and offset.X

c. Temperature Controller operation. The Temperature Controller

should click when the dial is rotated to settings above and

below the temperature of the kettle.X

Safety Valve pops

open

User

a. For air in the jacket. See “Jacket Vacuum” in the Maintenance

b. Temperature Controller dial setting.

Auth Service

Rep Only

c. For defective Temperature Controller. The relay should click

when the dial is rotated to settings above and below the

temperature of the kettle. If defective, replace.X

d. For defective safety valve. If the valve pops at pressures below

49 PSI, replace.X

Burners will not light

User

a. That the main gas supply valve is open. (handle is in line with

gas pipe).

b. Gas supply to the building.

c. That the kettle body is not tilted.

Auth Service

Rep Only

d. Temperature Controller operation. The relay should click

when the dial is rotated to settings above and below the

temperature of the kettle.X

e. That tilt limit switch is closed when body is not tilted.X

System does not

produce a

spark

Auth Service

Rep Only

a. AC voltage between terminals on secondary side of

transformer. If it is not 24 Volt, replace the transformer. X

b. That the high tension cable is firmly attached and in good

condition. If cracked or brittle, replace.X

c. Pilot electric ceramic for crack or break.X

d. Pilot spark gap. Regap.X

Safety valve leaks

a small amount of

steam when kettle

is operating

User

a. For contamination that prevents seating of the valve. With full

pressure in the jacket, pull the leer all the way briefly to blow

the valve clean, then let the lever snap back to seat the valve

Auth Service

Rep Only

b. Safety valve for defects. Replace any defective valve with an

identical valve. X

Spark is present

but the pilot will

not light

Auth Service

Rep Only

a. That the pilot valve is securely connected to terminals. X

b. For 24 VAC at terminals PV and PV/MV. If 24V is not present,

replace the ignition control module. X

b. That gas pressure is at least 3.5” W.C. (8.7818 ub).

c. For gas at the pilot. If it is not flowing:

(1) Check the pilot gas line for kinks and obstructions. X

(2) Clean orifice, if necessary. X

(3) Check magnetic operator for pilot valve on gas valve.

Repair or replace as necessary. X

d. That the pilot spark gap is located in the pilot gas stream. If

not, adjust or replace the pilot burner. X

e. For drafts. Shield the pilot burner, if necessary. X

Pilot lights, but

main burner will

not come on and

spark does not

stay on

Auth Service

Rep Only

a. For 24 V between terminals MV and PV/MV while pilot is burning.

If 24V is not present, replace the ignition control module. X

b. That gas pressure is at least 3.5” W.C.(8.7818 ub). X

c. Electrical connections of the main valve to terminals, to

assure that they are securely attached. Check magnetic

operator for main valve on gas valve. Repair or replace

as necessary. X

Pilot lights, but

main burner will

not come on, the

spark stays on

Auth Service

Rep Only

a. Check for bad burner ground. If necessary, repair with

high temperature wire. X

b. Pilot burner ceramic insulator for cracks. X

c. That cable is not grounded out. If it is, correct the

ground-out condition or replace cable. X

d. For proper gas pressure. X

e. Clean pilot assembly, or replace if necessary. X

f. Tighten all mechanical and electrical connections. X

g. If the pilot flame is weak, increase pilot orifice size. X

h. Replace ignition control module. X

Main burner

comes on but will

not stay on

Auth Service

Rep Only

a. Check burner ground for bad wire or connection. Replace

if necessary with high temperature wire. X

b. Check for low gas supply pressure. If necessary, replace

ignition control module. X

Summary of Contents for unified brands groen DH-20

Page 16: ...16 OM DH T DOMESTIC CE INTERNATIONAL Parts List GAS VALVE PIPING BOTTOM COMPONENTS ...

Page 27: ...27 OM DH T DOMESTIC CE INTERNATIONAL Wiring Diagram Domestic For Classic Control Models ...

Page 28: ...28 OM DH T DOMESTIC CE INTERNATIONAL Wiring Diagram Domestic For Advanced Control Models ...

Page 29: ...29 OM DH T DOMESTIC CE INTERNATIONAL Wiring Diagram CE ...