TL 1128 (TOP HOLES)

Issued August 2016

Revision No: 006

Printed in U.S.A.

Copyright 2016, Bayne Premium Lift Systems

Actuator Assembly Instructions

22

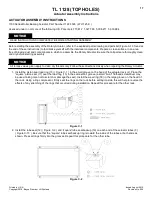

16.Thoroughly clean the bearing caps (8) ( Figure C-11 ) with a mild solvent and lubricate all seal grooves with STP oil

treatment. Place the bearing caps (8) on the table (mounting surface down) and install the wiper ring (19) in the

outside groove using a rubber mallet or small press.

(Avoid using tools that may damage seals or scratch

bearing cap or bearing surfaces.)

Turn the bearing cap (8) over. Collapse the pinion seal (20) and carefully work it

into the groove. Use fingers to carefully press the seal completely into the groove as shown in Figure C-11.

Be

careful not to score or scratch the sealing surface during the installation.

Install the bearing cap seal (15) and

thrust washer (32) into their respective grooves on the bearing cap mounting surface as shown in Figure C-11.

17.Coat the bearing cap seal area and pinion seal area shown in Figure C-11 lightly with STP Oil Treatment.

Figure C-11

18.Wrap masking tape or electrical tape around the pinion to cover the edges at the keyway. Slide the bearing cap

assembly over the pinion shaft with the bearing cap seal facing toward the actuator body and the flat surface of the

flange shown in Figure C-16 facing toward the actuator mounting flanges. Press against the bearing cap until the

shoulder seats against the actuator body, making sure that the seals remain in place. Install the bearing cap bolts

(21) ( Figure C-13 ) and lock washers (25). Hand tighten only at this time. Repeat this procedure for other bearing

cap. Document Number: 1900-0187 Issue Date: 01/22/14 Revision No: 004 Page: 26 of 53

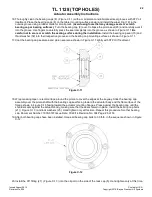

19.After both bearing caps have been installed, torque all bearing cap bolts to 30 ft-lb. in the sequence shown in Figure

C-12.

Figure C-12

20.Install the 90° fitting (27) ( Figure C-13 ) into the oil port on the side of the rack cap (5). Hand tighten only at this time.