5

VACUUMING YOUR POOL

When vacuuming your pool, depris is caught in the filter

at a very rapid rate. Consequently, the filter must work

harder, causing a rapid increase in filter pressure as will

be indicated on the pressure gauge. Frequent back-

washing could be necessary during this process de-

pending on the amount of dirt being vacuumed off the

pool floor. Keep a check on the pool water level and

refill as required.

MAINTENANCE

Preventative maintenance will provide continued smooth

performance and extend the life of your filter for many

years. Neglect will cause parts to wear or bind, leaks to

occur and result in costly repairs. Keep moving parts

lubricated and a clean environment around your filter

and related components.

LUBRICATION

There are various types of lubricants available.

However, most are intended for moving metal parts.

Unfortunately, these lubricants will harm or degrade the

plastics. DO NOT use petroleum base lubricants. Many

people consider “PETROLEUM JELLY” safe for babies

and can be applied to anything. But, it will DESTROY

most plastics. Silicone lubricants, available at your pool

dealer, are safe for use on plastics.

LUBE VALVE SHAFT AND O-RING

Periodically lubricate the valve shaft and internal

o-rings in your filter valve to maintain smooth

operations.

1.

Stuff a rag in the return fitting and into the bottom

inside outlet of your skimmer to reduce water back-

flow exiting the valve body when the piston assem-

bly is removed.

2.

Unscrew valve cover and pull piston assembly up

and out of valve body.

3.

Lightly lubricate the piston o-rings and valve shaft

with silicone lubricant.

4.

Reinstall piston assembly and remove rags from

skimmer and return fitting.

5.

Actuate piston assembly up and down to distribute

the lubricant, then resume normal operations.

REPAIRS

Servicing should be performed by a qualified dealer. If

disassembly is attempted, mark each of the parts

assembled position as it relates to its mating parts. This

assures proper alignment when reassembled.

Malfunction will occur if not properly assembled. See

your dealer for original replacement parts.

CAUTION

BEFORE removing filter or pump from pool for servic-

ing, prevent the backflow of water from your skimmer

and return inlet from flowing out of disconnected hoses.

1.

Remove skimmer cover and basket and plug inside

bottom hole with rag.

2.

Referring to the instructions for your return inlet,

remove the inlet cover and eye ball. Insert the

winterizing disc and reinstall the cover.

3.

Disconnect hoses on filter or pump as necessary

when removing for service or repairs.

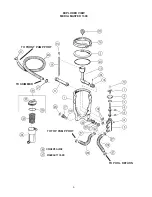

DRAIN TANK

See Caution Above

1.

Remove V-Clamp from filter and remove cover and

o-ring.

2.

Remove tank drain cap to drain.

3.

Place plastic bag over distributor in tank and secure

with a rubber band. Scoop out sand with a medium

size can and place in plastic bag.

4.

After servicing, reassemble and install in reverse.

Make sure tank o-ring and sealing areas are free of

any sand and that the o-ring is properly seated in

the cover groove before replacing cover.

WINTERIZING FILTER

In areas subject to freezing damage, it is mandatory that

the filter, pump and any related components be re-

moved from the pool and stored indoors. (Refer to

individual components owner's guide such as pump,

skimmer, chlorinator, etc., for specific winterizing

instructions.)

1.

Backwash the filter.

2.

Siphon pool water level down below skimmer

opening by using your vacuum hose and allow

water to flow to an area that can accept a couple of

thousand gallons or more.

3.

Remove V-Clamp from filter and remove cover and

o-ring.

4.

Remove tank drain cap and allow tank to drain fully.

5.

Disconnect all hoses.

6.

Place plastic bag over distributor in tank and secure

with a rubber band. Scoop sand out with a medium

size can and place in plastic bag. If sand is not

badly contaminated, save for next season.

7.

Store all components in a warm dry area indoors.

DAMAGE CAUSED BY FREEZING TEMPERATURES

IS NOT COVERED BY PRODUCT WARRANTY.