G643(E) Service Manual

Chapter 5. Engine Management System (EMS)

176

(

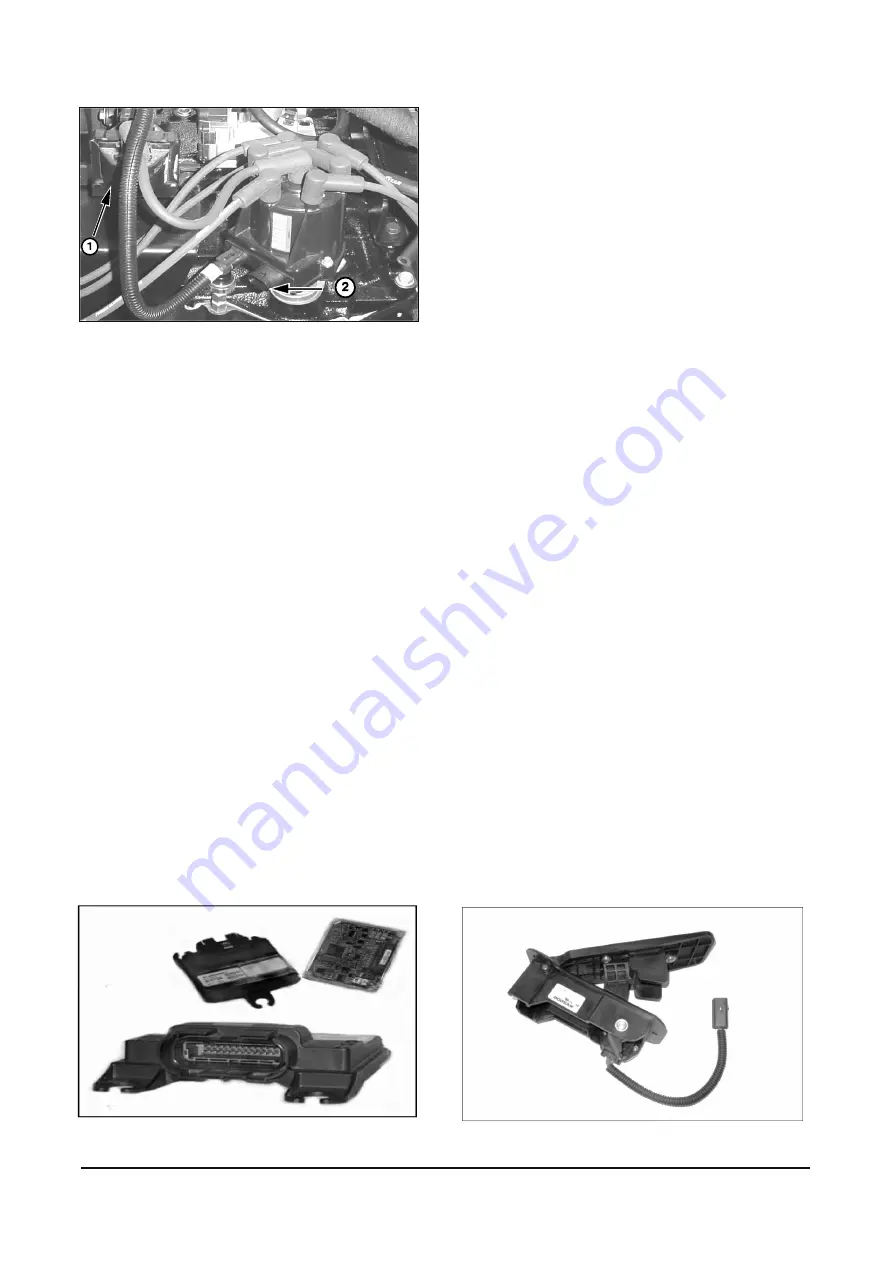

1)

Ignition Coil (

2)

Ignition Module

Figure 15. GM Ignition Module

The rising edge of the VR signal is converted to a

rising 5-volt signal by the ignition module. As the VR

signal passes back through zero volts, a falling edge

is created producing a square wave or digital signal,

similar to the signal produced by a Hall effect sensor.

This falling edge signal provides a stable engine

position reference at all engine speeds for the

SECM.

SECM

Small Engine Control Module (SECM) controller has

full authority over spark and air. the SECM has 24

pins of I/O and is fully waterproof and shock

hardened (

Figure 16

).

To optimize engine performance and drivability, the

SECM uses several sensors for closed loop

feedback information. These sensors are used by

the SECM for closed loop control in two main

categories:

•

Load/Speed

Management

•

Ignition

Management

Figure 16. Small Engine Control Module (SECM)

The SECM monitors system parameters and stores

any out of range conditions or malfunctions as faults

in SECM memory. Engine run hours are also stored

in memory. Stored fault codes can be displayed on

the Malfunction Indicator Light (MIL) as flash codes

or read by the Service Tool software through a CAN

(Controller Area Network) communication link.

Battery power (12 Vdc) is supplied through the fuse

block to the main power relay. The ignition key

switch is used to energize the main power relay. A

main power relay supplies 12 Vdc power to the

SECM, fuel lock-off, and the Smart Coil. The SECM

supplies positive voltage to the electronic throttle

actuator, oil pressure switch and the coolant

temperature sensor. Transducer or sensor power

(+5 Vdc) is regulated by the SECM and supplied to

the temperature/manifold air pressure sensor

(TMAP), throttle position sensor (TPS), and the

accelerator pedal position sensors (APP1 & APP2).

The SECM provides a constant voltage (VCC) to the

Smart Coil Driver, transducer ground for the all

sensors, and a low side driver signal controlling the

fuel lock-off and MIL.

SECM (Load/Speed Management)

Drive by wire refers to the fact that the MI-07 control

system has no throttle cable from the foot pedal

(Figure 17) to the throttle body. Instead, the SECM

is electronically connected both to the foot pedal

assembly and the throttle body. The SECM monitors

the foot pedal position and controls the throttle plate

by driving a dc motor connected to the throttle. The

dc motor actuates the throttle plate to correspond to

the foot pedal position when the operator depresses

the pedal.

The use of electronic throttle control (ETC) ensures

that the engine only receives the correct amount of

throttle opening for any given situation, greatly

improving idle quality and drivability.

Figure 17. Foot Pedal