•

Connecting rod bearing clearance

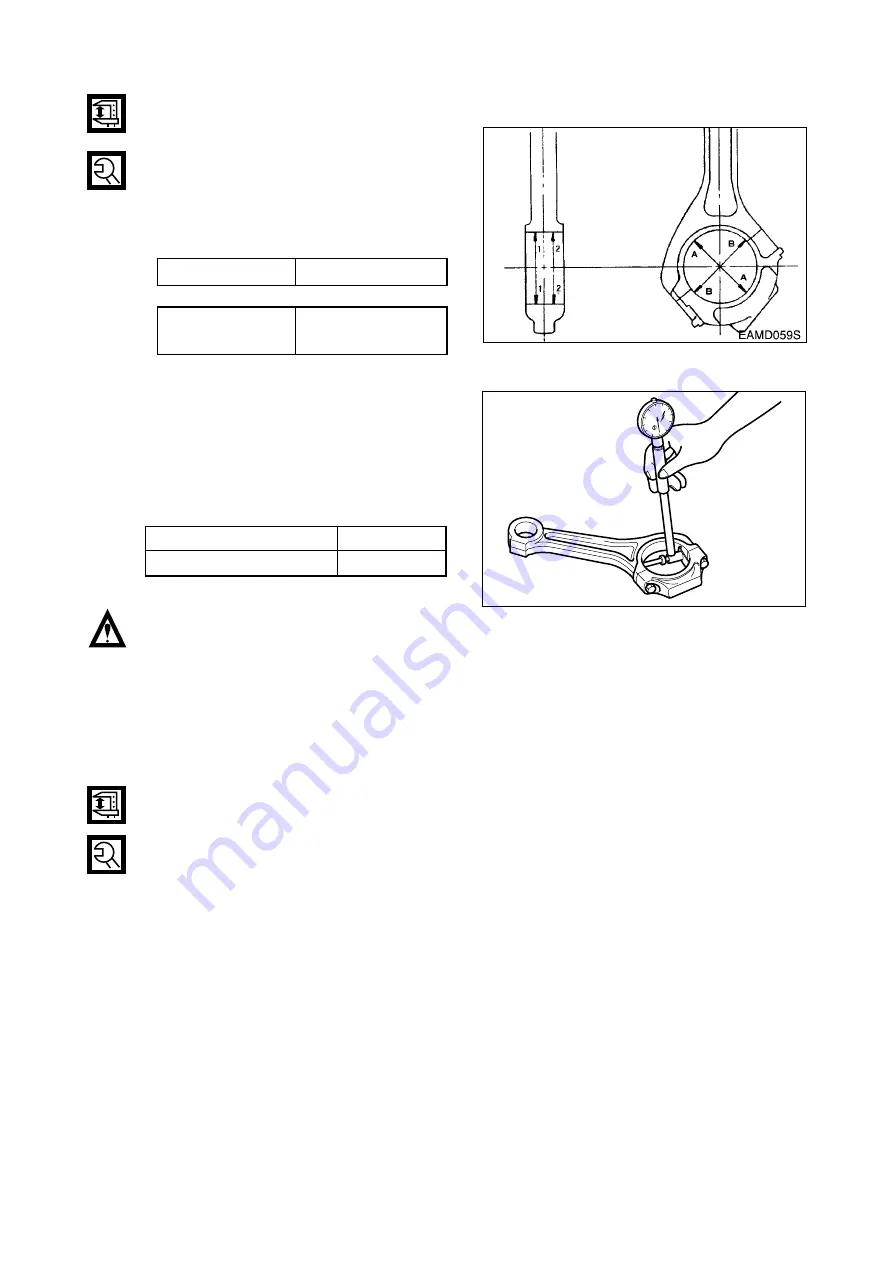

Install the connecting rod bearing in the

connecting rod bearing cap, tighten the

connecting rod cap bolts to the specified

t o r q u e ,

t h e n

m e a s u r e

t h e

i n s i d e diameter.

Compare the two values obtained

through measurement of connecting rod

bearing inside diameter with the outside

diameters of crankshaft pins to determine

the oil clearance.

•

If the clearance deviates from the

specified range, have the crankshaft

journals and pins ground and install

undersize bearings.

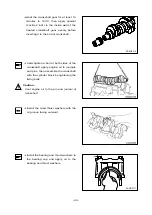

(2b) Oil clearance between crankshaft and bearing

(Method 2 : plastic gauge)

•

Assemble the crankshaft on the cylinder block and put plastic gauge on the journal and pin

of crankshaft and then after assembling bearing cap, tighten the bolts at the specific torque.

Again after disassembling the bearing cap by removing the bolts, take out the flatted plas-

tic gauge and measure the width of plastic gauge by means of plastic gauge measuring

scale. This is the oil clearance.

•

The oil clearance too can be measured in the same manner.

- 91 -

Torque

18 kg

.

m

Crank pin

70.791 ~

diameter

70.990 mm

EAMD060I

Standard

Limit

0.034 ~ 0.098 mm

0.25 mm

Summary of Contents for D1146

Page 1: ......

Page 57: ...7 2 Trouble Shooting 53 ...

Page 58: ... 54 ...

Page 59: ... 55 ...

Page 60: ... 56 ...

Page 61: ... 57 ...

Page 62: ... 58 ...

Page 63: ... 59 ...