•

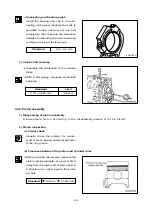

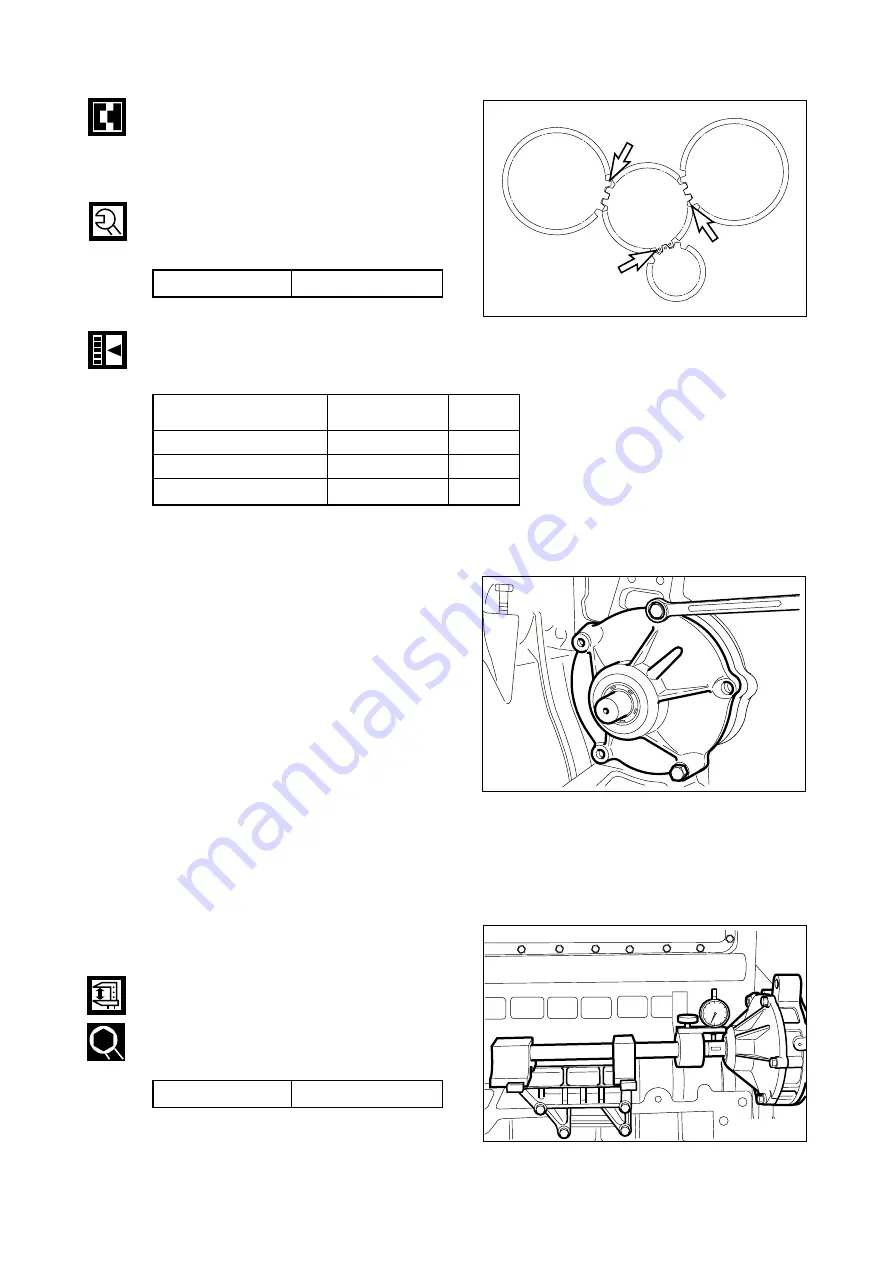

Install the idle gear by coinciding the

marks impressed on the crank gear, cam

gear, fuel injection pump drive gear, and

idle gear.

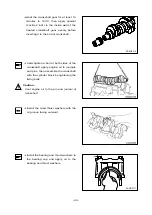

•

Install a thrust washer on the idle gear

and tighten to specified torque.

•

Check and adjust the amount of backlash

between gears using a feeler gauge.

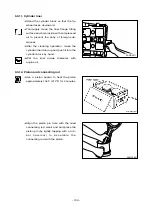

9.3.15. Injection pump flange

•

After assembling the fuel injection pump

g e a r t o t h e i d l e g e a r, t i g h t e n t h e

assembling bolts of the injection pump

flange.

•

Mount gasket by aligning the bolt holes

with the pin holes on the bearing

housing.

•

Turning the flywheel, adjust the pointer

to the 19

˚

position of the engraved scale.

•

After adjusting the injection timing of fuel

injection pump drive gear, tighten the fix-

ing bolts in the direction of fuel injection

pump.

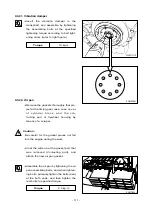

9.3.16. Injection pump

•

Install the injection pump bracket in the

cylinder block.

•

After measuring the amount of run-out

with an alignment setting jig,

disassemble the bracket, adjust the

shims, then reassemble it.

- 107 -

EA9M3015

Fuel injection

pump drive gear

Idle gear

Cranshaft gear

Cam

shaft

gear

Mark "0"

Mark "2"

Mark "1"

2

2

2

2

2

1

1

1

1

1

Torque

3.1 kg

.

m

Measuring position

Backlash

Limit

(between)

Cam gear & idle gear

0.16 ~ 0.28 mm 0.35 mm

Crank gear & idle gear

0.16 ~ 0.28 mm 0.35 mm

Injection pump & idle gear

0.16 ~ 0.28 mm 0.35 mm

EA9M3021

EAMD107I

Run out

0.2 mm or less

Summary of Contents for D1146

Page 1: ......

Page 57: ...7 2 Trouble Shooting 53 ...

Page 58: ... 54 ...

Page 59: ... 55 ...

Page 60: ... 56 ...

Page 61: ... 57 ...

Page 62: ... 58 ...

Page 63: ... 59 ...