42

OPTIONS

7/53

BUNDED BASE

DESCRIPTION

This machine can be fitted with bund equipment to contain leakages

and spillages, which occur within the machine enclosure.

The bund will contain all fluids normally installed in the machine, plus

an additional 10%.

When fitted with bund, the machine must only be operated when level.

Drains for engine coolant, engine oil and compressor oil, fuel tank and

bunded base drains are located at the left rear side of the machine.

Bunded based to be drained daily

DRAINING OF CONTAMINATED FLUIDS

Contaminated fluid must be removed by authorized personnel only.

Captured fluids can be drained from the bund by removing the plug or

uncoupling the flexible pipe secured at the left side of the machine. The

plug must be re-sealed after draining. The flexible pipe must be re-

secured after draining.

DRAINING OF MACHINE FLUIDS

During maintenance operations drain machine fluids using the drain

ports indicated.

GENERATOR

SAFETY

Refer to the SAFETY SECTION in this manual.

GENERAL INFORMATION

Rated output

4,8 kW @ 0,8 Power factor

(PF) lagging

Rated voltage

110V 1ph or 230V 1ph or 230V 3ph or

400V 3ph + 230V 1ph @ 3000 revs

min-1

Voltage regulation

+/- 6%

Maximum continuous output

6 kVA @ 0,8 PF

Rotor type

Brushless

(110/230V 1ph)

Rotor type

Rotating armature with sliprings

(230V 3ph / 400V 3ph + 230V 1ph)

De-rating factors at 0.8 pf continuous load:

Air in temp 20°C

Continuous

Air in temp 30°C

5,7 KVA @ 0.8 p.f continuous

Air in temp 46°C

4,5 KVA @ 0.8 p.f continuous

De-rating factors for intermittent load:

Air in temp 20-35°C,55 mins/hr @ 0.8, 5 mins off load

Air in temp 35-40°C,50 mins/hr @ 0.8, 10 mins off load

Air in temp 40°C + ,45 mins/hr @ 0.8, 15 mins off load

Socket outlets:

110V 1ph & 230V 1ph

1 x 32 amperes

2 x 16 amperes

230V 3ph

1 x 16 amperes

400V 3ph + 230V 1ph

400V 3ph = 1 x 16 amperes

230V 1ph = 2 x 16 amperes

Earth leakage protection is provided by a single residual current

device. Miniature circuit breakers (MCB) are fitted to provide both

overcurrent and short circuit protection for the generator.

Each socket outlet is protected by a spring loaded weather–proof

cover.

OPERATING INSTRUCTIONS

A mode selector switch is provided to switch the machine between

compressor and generator mode.

When the switch is in the

Generator

position the normally-open

solenoid valve switches to the closed position and air in the line to the

engine speed control cylinder vents to the atmosphere via the solenoid

exhaust port. This causes the cylinder to move to its maximum speed

position. The engine will now maintain maximum speed as the air line

from the pressure regulator valve to the solenoid valve is now closed.

When the switch is returned to the

Compressor

position, the solenoid

valve is de-energised thus returning it to its normally open position. The

engine speed cylinder would then respond via the pressure regulator

valve according to the air demand.

When connecting electrical equipment to any of the socket outlets, it is

recommended that the appropriate MCB is in the

OFF

position before

making the connection, switching the MCB to the

ON

position

immediately prior to using the equipment.

WARNING: Major leakages or spillages must be drained before

the machine is towed.

CAUTION:

Do not start or stop the machine with the compressor/

generator mode switch in the

Generator

position.

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

Page 11: ...DECALS 7 7 53 Engine oil drain...

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

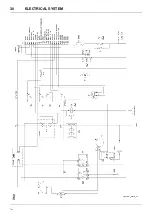

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

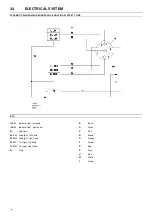

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......