18

OPERATING INSTRUCTIONS

7/53

COMPRESSOR MOUNTING

Portable compressors, which are modified to remove the running gear

and mount the compressor directly to trailers, truck beds or frames, etc.

may experience failure of the enclosure, frame, and/or other

components.

It is necessary to isolate the compressor package from the carrier

basewith a flexiblemounting system. Such a system must also prevent

detachment of the package from the carrier base in the event the

isolators fail.

Contact your Portable Power representative for flexible mounting kits.

Warranty does not cover failures attributable to mounting of the

compressor package to the carrier base unless it is a Portable Power

provided system.

NOTE:

The maintenance schedule in this manual describes the

service intervals that should be followed for normalapplications of this

compressor. This page may be reproduced and used as a checklist

by service personnel.

In more severe applications such as sandblasting, quarry drilling, well

drilling, and oil and gas drilling, more frequent service intervals will be

required to ensure long component life.

Dust and dirt, high humidity, and high temperatures will affect

lubricant life and service intervals for components such as inlet air

filters, oil separation elements and oil filters.

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

Page 11: ...DECALS 7 7 53 Engine oil drain...

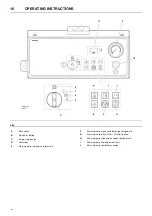

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

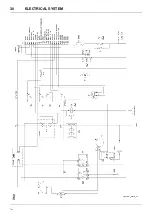

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......