24

MAINTENANCE

7/53

BRAKES

Check and adjust the brake linkage at 500 miles (850Km) then every

3000 miles (5000Km) or 3 months (whichever is the sooner) to

compensate for any stretch of the adjustable cables. Check and adjust

the wheel brakes to compensate for wear.

Adjusting the overrun braking system

1. Preparation

Jack up the machine

Disengage the handbrake lever [1].

Fully extend the draw bar [2] on the overrun braking system.

Requirements:

During the adjustment procedure always start with the wheel brakes.

Always rotate the wheel in the direction of forward movement.

Ensure that an M10 safety screw is fitted to the handbrake pivot.

The brake actuators must not be pre-tensioned - if necessary loosen

the brake linkage [7] on the brake equalisation assembly [8].

Check that brake actuators and cables [11] operate smoothly.

2. Brake Shoe Adjustment

Tighten adjusting screw [12] clockwise until the wheel locks.

Loosen adjusting screw [12] anti-clockwise (approx. ½ turn) until the

wheel can be moved freely.

Slight dragging noises that do not impede the free movement of the

wheel are permissible.

This adjustment procedure must be carried out as described on both

wheel brakes.

When the brake has been adjusted accurately the actuating distance

is approximately 5-8mm on the cable [11]

1. Handbrake lever

2. Draw bar and bellows

3. Handbrake lever pivot

4. Transmission lever

5. Brake cable

6. Breakaway Cable

7. Brake linkage

8. Equalisation assembly

9. Compression spring

10.Equaliser plate

11.Cable

CAUTION:

The compression spring [9] must only be lightly pre-

tensioned and when operating must never touch the axle tube.

Never adjust the brakes at the brake linkage [7].

12.Adjusting screw

13.Cable entry

Width across flats of adjusting screw [12]

Brake size

Key width

160x35 / 200x50

SW 17

250x40

SW 19

300x60

SW 22

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

Page 11: ...DECALS 7 7 53 Engine oil drain...

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

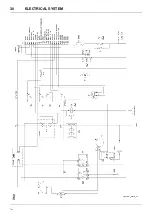

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

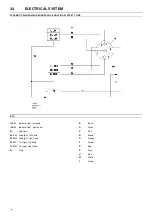

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......