OPTIONS

53

12/150_23136591

−

C en

MAINTENANCE

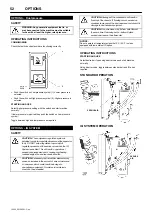

DAILY MAINTENANCE

Verify, during full

−

load (maximum compressed air delivery) that the

IQ system filter restriction indicators do not show excessive

restriction.

The gauge shown above will display IQ system outlet pressure.

Compare this value to full system pressure shown on the control

panel. If so equipped, an automatic restriction indicator is located

behind the filter mounting bracket which will shut down the

compressor if restriction exceeds recommended values.

WEEKLY MAINTENANCE

Verify that the piping from the water separator and filters to the

exhaust system is not clogged.

YEARLY MAINTENANCE

The normal maintenance interval on the primary and secondary IQ

System filters is one year, or earlier if pressure drop becomes

excessive.

The pressure gauge mounted above the filters will show outlet

pressure. When compared with control panel gauge pressure, the

difference in pressure is the pressure drop over the IQ filter

elements.

The optional pressure drop sensor will indicate a need to change the

filter elements with a warning light on the control panel.

FILTER REPLACEMENT.

Remove all wires and hoses connected to drains on bottom of each

filter housing. Inspect fittings and hoses for any blockage. Clean if

necessary.

Using a chain wrench or similar tool, loosen the housing. The

housing should be removed by hand after loosening, taking care to

prevent the housing from falling to the floor panel.

Lower the housing to floor panel. Remove and replace the filter

element, being careful not to damage outer wrap.

Put a small amount of petroleum jelly or other non

−

synthetic grease

on the element o

−

ring to aid installation into the filter head.

Replace housing making sure not to overtighten.

Repeat the above procedure on the remaining filter element.

Reconnect all wires and hoses to drains on bottom of each filter

housing.