MAINTENANCE

35

12/150_23136591

−

C en

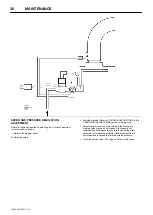

Completely drain the receiver/separator system including the piping

and oil cooler by removing the drain plug(s) and collecting the used

oil in a suitable container.

Replace the drain plug(s) ensuring that each one is secure.

NOTE:

If the oil is drained immediately after the machine has been

running, then most of the sediment will be in suspension and will

therefore drain more readily.

CAUTION:

Some oil mixtures are incompatible and

result in the formation of varnishes, shellacs or lacquers

which may be insoluble.

NOTE:

Always specify PRO

−

TEC

oil for use at all ambient

temperatures above

−

23

C.

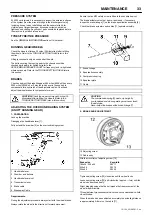

COMPRESSOR OIL FILTER ELEMENT

Refer to the

SERVICE / MAINTENANCE CHART

in this section for

service intervals.

RUNNING GEAR WHEEL BEARINGS

Wheel bearings should be packed with grease every 6 months. The

type of grease used should conform to specification

MIL

−

G

−

10924.