5

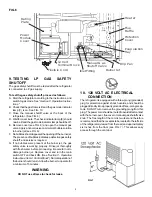

9. TESTING LP GAS SAFETY

SHUTOFF

The gas safety shutoff must be tested after the refrigerator

is connected to LP gas supply.

To test the gas safety shutoff, proceed as follows:

A. Start the refrigerator according to the instructions, and

switch to gas mode. See "

Section C. Operation Instruc-

tions."

B. Check that the gas flame is lit and the gas mode indicator

lamp (C) is on. See FIG. 10.

C. Close the manual shutoff valve at the back of the

refrigerator. (See FIG. 6)

D. Wait for one minute. The check indicator lamp (E) should

now be lit and the gas mode indicator lamp should be off.

E. Remove cover (see FIG. 6) and open the manual gas

valve. Apply a noncorrosive commercial bubble solution

to burner jet (see FIG. 6).

F. No bubbles should appear at the opening of the burner jet.

The presence of bubbles indicates a defective gas safety

shutoff, and service is required.

G. If no bubbles were present at the burner jet, the gas

safety valve is working properly. Rinse jet thoroughly

with fresh water before proceeding. Be careful not to

damage burner jet. Replace cover and turn the main

switch OFF and back ON. (See "

Section C. Operation

Instructions, Item 2. Control Panel"). Normal operation of

the burner should return. Allow the burner to operate for

a minimum of 5 minutes.

WARNING

DO NOT use a flame to check for leaks.

10. 120 VOLT AC ELECTRICAL

CONNECTION

The refrigerator is equipped with a three-prong (grounded)

plug for protection against shock hazards, and should be

plugged directly into a properly grounded three-prong recep-

tacle. DO NOT cut or remove the grounding prong from this

plug. The power cord should be routed to avoid direct contact

with the burner cover, flue cover or manual gas shutoff valve

knob. The free length of the cord is two feet and therefore

recommended that the receptacle be located to the left side

of the refrigerator (viewed from the rear) and approximately

six inches from the floor (see FIG. 7). This allows easy

access through the vent door.

FIG. 7

Flexible C ord

12 V olt

Terminal B lock

Inlet F itting

Manual G as

Shutoff V alve

Burner Jet

Drip P an

Evaporation

Tray

Protection

Cover

Flue

Baffle

Heater

Power

Module

Cover

Rating

Plate

FIG. 6