2

SECTION A. INSTALLATION

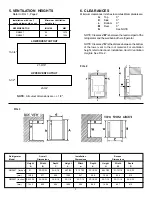

2. VENTILATION

The installation shall be made in such a manner as to

separate the combustion system from the living space of the

mobile home or recreational vehicle. Openings for air supply

or for venting of combustion products shall have a minimum

dimension of not less than 1/4 inch.

Proper installation requires one fresh air intake and one

upper exhaust vent. The ventilation kits shown in this

instruction manual have been certified for use with the

refrigerator model listed in the Table. For "Certified Vent

System Kits" see Section B. The ventilation kits must be

installed and used without modification. An opening toward

the outside at floor level in the refrigerator compartment must

be provided for ventilation of heavier-than-air fuel gases. The

lower vent of the recommended kits is provided with proper

size openings. The flow of combustion and ventilation air

must not be obstructed.

NOTE: The upper vent should be

centered over the condenser coil

at the back of the refrigerator.

FIG. 1

1. GENERAL INSTRUCTIONS

This appliance is designed for storage of foods and

storage of frozen foods and making ice.

The refrigerators outlined herein have been design certified

by A.G.A. under ANSI Z21.19 Refrigerator Standard for

installation in a mobile home or recreational vehicle and are

approved by the Canadian Gas Association.

The certifications are, however, contingent on the installa-

tion being made in accordance with the following instructions

as applicable.

In the U.S.A., the installation must conform with:

1. National Fuel Gas Code ANSI Z223.1-(latest edition)

2. Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280

3. Recreational Vehicles ANSI A119.2-(latest edition).

The unit must be electrically grounded in accordance with

the National Electric Code ANSI/NFPA 70-(latest edition)

when installed if an external alternating current electrical

source is utilized.

4. Any applicable local code.

In Canada, the installation must conform with:

1. Current CGA B 149 Gas Installation Codes

2. Current CSA Standard Z 240.4 GAS-EQUIPPED REC-

REATIONAL VEHICLES AND MOBILE HOUSING

3. Any applicable local code

The unit must be electrically grounded in accordance with

the CANADIAN ELECTRICAL CODE C 22 Parts 1 and 2.

The lower side vent is fitted with a panel which provides an

adequate access opening for ready serviceability of the

burner and control manifold of the refrigerator. This should be

centered on the back of the refrigerator.

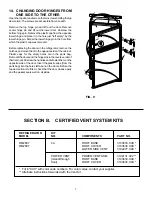

3. CERTIFIED INSTALLATION

Certified installations require one roof vent and one lower

side vent.

For certified vent system kits, see Section B.

For further information, contact your dealer or distributor.

4. METHOD OF INSTALLATION

The method of installation is shown in FIG. 1. It is essential

that all maximum or minimum dimensions are strictly main-

tained as the performance of the refrigerator is dependent on

adequate flow of air over the rear of the refrigerator.