32

3. After approximately 10 seconds press knob (E) several times. After

ignition, hold down knob (B) for a further 20-30 seconds before

releasing.

The flame can be controlled by aperture (C).

Should no ignition occur, repeat the ignition process after 1 minute.

(This could take longer than 10 seconds if the unit has been out of

operation for a prolonged period or after replacing the gas cylinder.

Cause: air in the lines).

4. Once sufficient refrigeration has been obtained in the cooling tank at the

MAX position, the control knob should be turned to the MIN position by

low outside temperatures or when the refrigerator is only lightly loaded

respectively the ambient temperature is below +18°C, in order to avoid

overfreezing the contents.

12. Shutting down gas operation

1. Close gas cylinder or pressure regulating valve.

2. Turn knob (B) clockwise to the off position.

13. Food and drink storage

Foodstuffs and drinks should always be sealed when stored in the

cooling unit. Thus, changes in taste and smell are avoided.

Food and drink should be so placed in the cooler so as to allow air to

circulate freely.

Do not place hot food or drinks in the cooler!

Under no circumstances should inflammable liquids and/or gases be

stored in the cooler. Explosion hazard!

14. Defrosting and measures for prolonged

periods of disuse

A build up of too much ice on the evaporator hinders cooling of the unit and

thus reduces effectiveness. When there is an approximately 5-mm-thick

layer of ice build-up it is recommended to defrost the cooling unit. Thus, the

cooling unit will be turned off and any goods to be cooled removed. Never

use heated appliances, heaters, etc. to speed up the defrosting process! If

necessary, a cloth dipped in warm water can be placed on the unit to help

the defrosting process. After defrosting, clean up the defrosted water with a

clean cloth and clean the cooler containers as described in chapter 4.

GB

Summary of Contents for RC1600

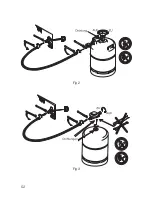

Page 11: ...51 Fig 1...

Page 12: ...52 Fig 3 Fig 2...

Page 13: ...53 Fig 5 Fig 4 joint guarnizione afdichting junta joints guarnizione afdichtingen junta...

Page 14: ...54...

Page 15: ...55...