13

MN1617

WARNING: The Dodge Quantis MSM and its connected

equipment and accessories must be guarded. Rotating

parts such as couplings, pulleys, fans and unused shaft

extensions must be permanently guarded by the user

against accidental contact with personnel and their

clothing. The surface temperature of the Dodge Quantis

MSM enclosure may reach temperatures which can cause

discomfort or injury to personnel accidentally coming into

contact with hot surfaces. The user should provide guards to

prevent accidental contact with hot surfaces. Guards must

be sufficiently rigid to maintain adequate guarding in normal

service.

WARNING: Threaded hardware used to mount the Dodge

Quantis MSM Unit must be SAE Grade 5 or Metric Class 8.8

or better. DO NOT USE HARDWARE OF A LOWER GRADE.

MAINTENANCE

Check oil levels and oil quality regularly. Change oil at the

intervals specified in the Lubricants section of this document.

Check alignments of drive components regularly. Check chain

and belt tensions and hardware tightness periodically too.

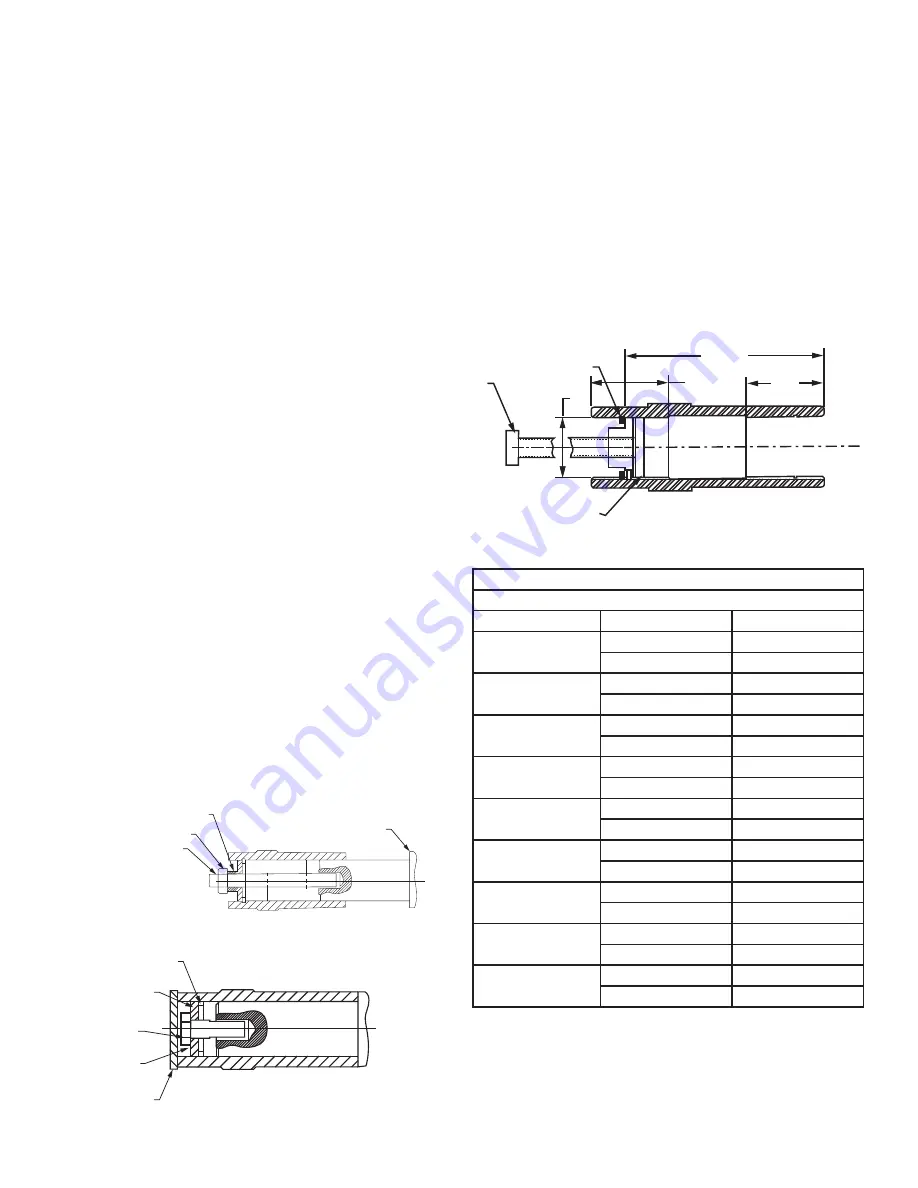

Assembly/Disassembly Motorized Shaft

Mount (MSM) Reducer

Please follow the instructions outlined below when assembling

and disassembling this unit. Failure to follow the instructions as

outlined may result in damage to the gear unit or to the machine’s

drive shaft. For ease of assembly, it is recommended that the

machine’s drive shaft be chamfered. DO NOT HAMMER THE

GEARBOX SHAFT ONTO THE MACHINE’S DRIVE SHAFT.

The machine’s drive shaft should be produced in accordance

with the dimensions shown on the accompanying Table 5 or 6.

Assembly

All shaft mounted gearboxes are furnished with A) Retaining

Ring B) Keeper plate C) Retaining Bolt D) Spring Washer E) Dust

Cap and Anti-Seize as shown in the finished assembly, Figure

5. Apply the anti-seize onto the customer shaft before installing

reducer onto the shaft. The gearbox is pulled onto the shaft by

means of a threaded rod and nut assembly as shown in Figure

4 below. The threaded rod and spacer are not supplied. The

threaded rod (M) is specified in Table 5 or 6. After the gearbox

has been pulled completely onto the machine shaft firmly against

the machine shaft’s backing shoulder, it must be locked in place

with the retaining bolt tightened to the tightening torque shown in

Table 4.

Disassembly

Prior to disassembly, the dust cap, retaining bolt, spring washer,

keeper plate and retaining ring must be removed. For ease of

disassembly, it is recommended that the following tools be made

and used as described: The round keyed nut (A) is inserted into

the free space between the retaining ring in the gear unit’s hollow

shaft and the end of the machine’s drive shaft. The removal bolt

(B) is screwed into the nut (A) which presses a disk (C) against

the machine’s drive shaft. The resulting force pushes the gearbox

off of the machine’s drive shaft. Reference Figure 6 for the

disassembly arrangement.

NOTE: The retaining bolt supplied with the gear unit cannot

be used for this purpose and must be replaced with the

bolt specified in Table 5 or 6. The round keyed nut and disk

should be made from 1045 steel and removal bolt should be

a minimum of SAE Grade 5.

Table 4–Tightening Torques for Retaining Bolt

Recommended Tightening Torque for Retaining Bolt

Unit Size

Bolt Thread Size (M)

Torque

MW38

3/8–16

248 in-lb

M10

16 N-m

MW48

3/8–16

248 in-lb

M12

28 N-m

MW58

5/8-11

611 in-lb

M16

69 N-m

MW68

5/8–11

611 in-lb

M16

69 N-m

MW88

¾–10

1221 in-lb

M16

69 N-m

MW108

¾–10

1221 in-lb

M20

138 N-m

MW128

¾–10

1221 in-lb

M20

138 N-m

MW148

¾–10

1221 in-lb

M20

138 N-m

MW168

1–8

2098 in-lb

M24

237 N-m

SPACER

NUT

THREADED ROD

Machine’s Drive Shaft

Backing Shoulder

Figure 4 – Threaded Rod and Nut Assembly

B

C

D

E

A

Figure 5 – Finished Assembly

B

A

U

C

M4

M4

VG

Figure 6 – Disassembly Arrangement