1

Saw Operaton, Job Entry, Machne Setup, I/O Status

1.

When the operator selects one of these choices,

there is a group of sub-menus screens in which to

set saw parameters and/or job data. Use the

Next

Screen

function key to scroll through these group

of sub-menus screens. When the last sub-menu

screen is shown, pressing the Next Screen function

key will bring the operator back to the first screen

again. Then the operator may choose another

function.

2.

Pressing the

""

key takes the operator to a group

of sub-menus that allows the operator to set cer-

tain machine parameters. These parameters were

described in the previous section.

3.

Press the

"6"

key to see the JOB ENTRY group of

sub-menu screens.

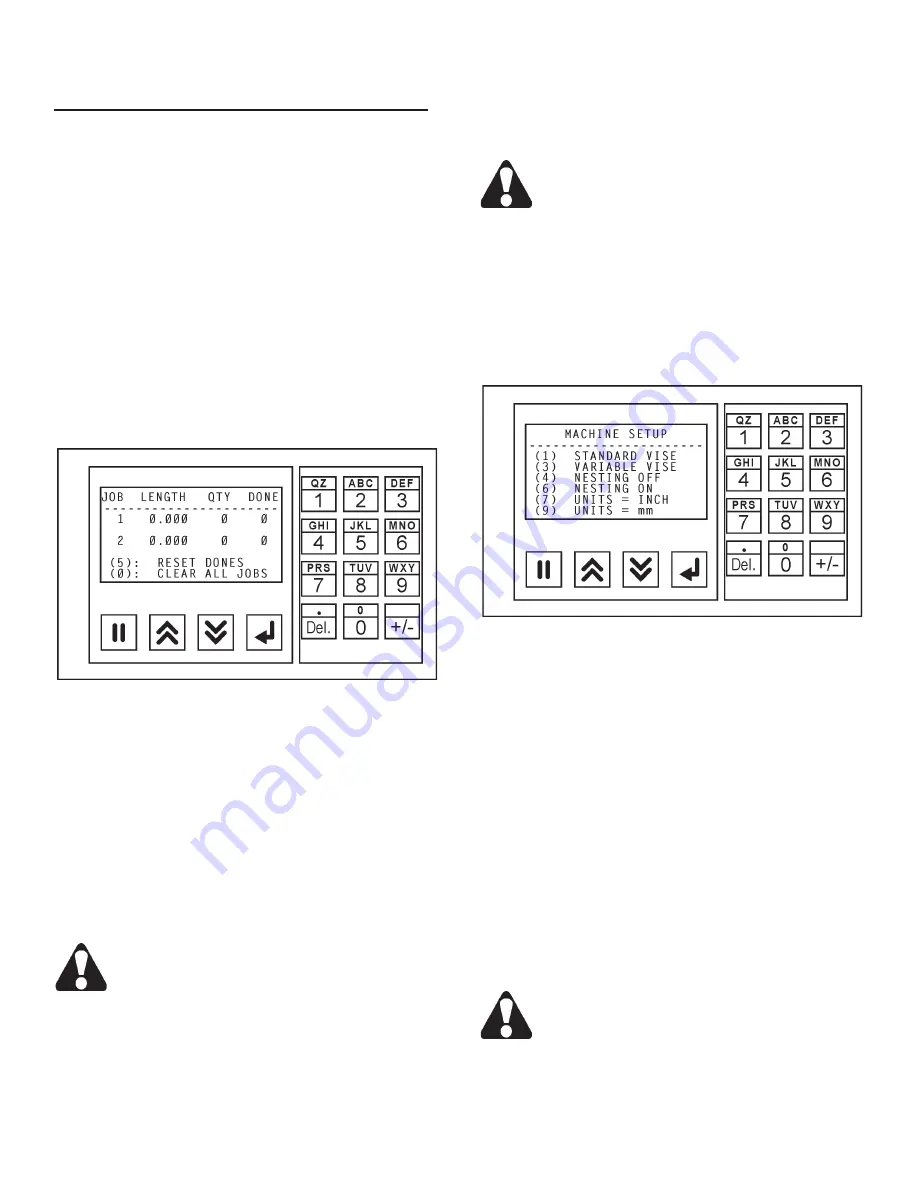

Job Entry Screen.

•

To enter data, press the

Data Entry

function key.

Then:

(a)

With the length field highlighted, enter

the length of the cut using the numeric keypad;

(b)

Press the

Accept

function key to enter the data

into memory;

(c)

With the quanitity field highlighted,

enter the number of cuts using the numeric keypad;

(d)

Press the

Accept

function key to enter the data

into memory;

(e)

With the next job's field highlighted,

continue as above;

(d)

When there is no highlighted

field, press the

Next Screen

key to move to the next

set of two (2) jobs to be programmed.

If you make an error n enterng data, just press

the Data Enter key agan, change your entry

and then press the Accept key.

•

Continue the sequence as described until all jobs

desired are entered. The operator can exit the

screen by using either the

Next Screen

or

Prevous

Screen

function keys through the sub-menu and the

operator will be brought back to the first screen.

•

To RESET DONES, press the

"5"

key on the numeric

keypad.

•

To CLEAR ALL JOBS, press the

"0" (zero)

key on

the numeric keypad.

Pressng the CLEAR ALL JOBS wll completely

clear the contents of the job lst. All data wll

be lost.

•

To skip a job or jobs in a list, set the quantities to

"0"

(zero) on those jobs to be skipped.

4.

Press the

"7"

key to see the MACHINE SETUP

group of sub-menu screens.

•

A blinling star symbol after a selection indicates that

this control is in operation.

Machine Setup Screen.

•

Press the

"1"

key on the numeric keypad for STAN-

DARD VISE pressure; press the

"3"

key for VARI-

ABLE VISE pressure (see

"Accessories"

section in

this manual for use of the Variable Vise Pressure

feature).

•

Press the

""

key on the numeric keypad for

NESTING OFF (which means the optional nesting

clamping bar is NOT operational); press the

"6"

key

for NESTING ON for vise sequence which allows

a time delay for the nesting clamping bar to clamp

the material. One vise is always clamped to keep

the bundled material in place.

•

To use and display INCH measurements, press the

"7"

key on the numeric keypad; for metric measure-

ments (mm), press the

"9"

key.

Changng between the INCH and mm settngs

wll requre that any data entered for cut length

and kerf wdth wll need to be changed also.

For example, a 6 inch cut will switch to a 6 mm

cut and vce versa.

MACHINE CONTROLS (Continued....)

Summary of Contents for DC-330NC

Page 1: ......

Page 5: ...MACHINE DIMENSIONS FLOOR PLAN INCHES 03 MILLIMETERS 1 mm...

Page 6: ...MACHINE DIMENSIONS Continued INCHES 03 MILLIMETERS 1 mm FRONT VIEW...

Page 7: ...MACHINE DIMENSIONS Continued INCHES 03 MILLIMETERS 1 mm SIDE VIEW...

Page 8: ...MACHINE FEATURES FRONT VIEW...

Page 9: ...MACHINE DIMENSIONS Continued REAR VIEW...

Page 10: ...MACHINE DIMENSIONS Continued PROXIMITY LIMIT SWITCH LOCATIONS TOP VIEW...

Page 27: ...23 LUBRICATION NEXT 2 PAGES...