6400-065-T-8-12

4

•

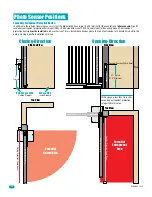

For gate operators utilizing contact sensors:

1. One or more contact sensors shall be located where the risk of entrapment or obstruction exist, such as at the

leading edge, trailing edge, and post mounted both inside and outside of a vehicular horizontal slide gate.

2. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3. One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4. A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor

and the gate operator is not subjected to mechanical damage.

5. A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstructions. A wireless contact sensor shall function

under the intended end-use conditions.

6. One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

Vehicular gate operator products provide convenience and security. However, gate operators must use high levels of force

to move gates and most people underestimate the power of these systems and do not realize the potential hazards associ-

ated with an incorrectly designed or installed system. These hazards may include:

•

Pinch points

•

Entrapment areas

•

Reach through hazards

•

Absence of entrapment protection devices

•

Improperly located access controls

•

Absence of vehicle protection devices

•

Absence of controlled pedestrian access

In addition to these potential hazards, automated vehicular gate systems must be installed in accordance with the UL 325

Safety Standard and the ASTM F2200 Construction Standard. Most lay persons are unaware of, or are not familiar with,

these standards. If an automated vehicular gate system is not properly designed, installed, used and maintained, serious

injuries or death can result. Be sure that the installer has instructed you on the proper operation of the gate and gate

operator system.

Be sure that the installer has trained you about the basic functions of the required reversing systems associated with your

gate operating system and how to test them. These include reversing loops, inherent reversing system, electric edges,

photoelectric cells, or other external devices.

•

This Owner’s Manual is your property. Keep it in a safe place for future reference.

•

Be sure that all access control devices are installed a minimum distance of 10 feet away from the gate and gate

operator, or in such a way that a person cannot touch the gate or gate operator while using the device. If access

control devices are installed in violation of these restrictions, immediately remove the gate operator from service

and contact your installing dealer.

•

Loops and loop detectors, photo-cells or other equivalent devices must be installed to prevent the gate from

closing on vehicular traffic.

•

The speed limit for vehicular traffic through the gate area is 5 MPH. Install speed bumps and signs to keep

vehicular traffic from speeding through the gate area. Failure to adhere to posted speed limits can result in

damage to the gate, gate operator, and to the vehicle.

•

Be sure that all persons who will use the gate system are familiar with the proper use of the gate and gate

operator and are familiar with the possible hazards associated with the gate system.

•

Be sure that warning signs are permanently installed on both sides of the gate in an area where they are fully

visible to traffic.

•

It is your responsibility to periodically check all entrapment protection devices. If any of these devices are

observed to function improperly, remove the operator from service immediately and contact your installing or

servicing

dealer.

•

Follow the recommended maintenance schedule.

•

Do not allow children to play in the area of the operator or to play with any gate-operating device.

•

To remove the gate operator from service, operate the gate to the full open position and then shut off power to

the operator at the service panel.

Important Notices

Summary of Contents for 6400 - UL 325 Class 1

Page 2: ......

Page 21: ...6400 065 T 8 12 19 ...