4

1.3.2 NFPA 484, Light Metals

1.3.3 Other requirements

1.4 Electrical hazards

1.5 Rotating equipment

1.6 Safety guards

There are various methods for dealing with a dust explosion hazard. The Typhoon Central Dust Collector is particularly appropriate for the collection of

dust generated by the working of light metals such as aluminum, titanium and magnesium. These dusts are highly explosive and the Typhoon Central

Dust Collector uses water as a medium for neutralizing the development of a potentially explosive dust cloud and for eliminating the possibility of ignition.

The specific standard that applies to these applications is

NFPA 484: Standard for Combustible Metals

. This standard applies to “the production,

processing, finishing, handling, recycling, storage, and use of all metals and alloys that are in the form that is capable of combustion or explosion”. When

the Typhoon Central Dust Collector is used to collect dust from the working of light metals, the user shall be fully conversant with the provisions of NFPA

484 and shall comply in full with all of its requirements.

The use of a dust collector for the collection of explosive dust is only one part of a safe dust prevention and mitigation program. Dust shall not be

allowed to accumulate or build up on the surfaces of the dust collector, on the air intakes or in the surrounding area. The owner’s attention is directed

particularly to the “Housekeeping” chapters in NFPA 654 (Chapter 8 in the 2013 edition) or NFPA 484 (Chapter 7 in the 2015 edition). If any of the

other codes and standards referenced above applies, consult the appropriate chapters in those documents.

The editions referenced here were current at the time of writing. Be aware that they may have changed. When referring to NFPA standards, the user

shall ensure that they are working with the most current edition.

For information on NFPA

®

standards, go to http://www.nfpa.org/. NFPA provides free on-line read-only access to its codes and standards. Standards

may also be purchased.

Before doing any work on the Diversitech equipment make sure that all potential electrical hazards have been identified and that all electric current

connected to the equipment, and to any connected or associated equipment, has been properly disconnected and securely locked-out to prevent

accidental reconnection prior to completion of the work. All electrical work shall be done in full accordance with the current edition of NFPA 70, the

National Electrical Code, and all other applicable laws, rules, and regulations. All electrical work shall be performed by a licensed electrician. Only

original Diversitech parts shall be used as replacements for ongoing maintenance and repair.

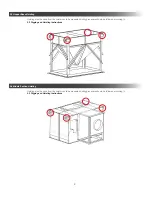

The Typhoon Central Dust Collector incorporates a fan which is close-coupled and installed on top of the Typhoon Central Dust Collector, or installed

separately (typically ground mounted) and ducted to the outlet of the Typhoon Central Dust Collector. The fan impeller (fan wheel) may rotate at

nominal speeds approaching 3600 rpm and has the potential to cause severe injury. The fan impeller can be accessed through the collector from

inside the cabinet if the moisture eliminator is removed, from the outside of the collector through the collector discharge, or from the connecting inlet or

outlet ductwork. All due care should be exercised to avoid any contact with the operating fan. Under no circumstances should the fan ever be allowed

to operate when any of the access panels on the dust collector, silencer, or connecting ductwork have been removed. The fan must be disconnected

and locked out prior to the performance of any maintenance work, see paragraph 1.4.

The dust collector cabinet prevents access to the fan inlet. All access panels and ducts shall remain bolted in place while the fan is operating. Prior to

the removal of any access panel or ducts the electrical power to the collector shall be disconnected and locked out, see 1.4 and 1.5.

After electrical power is disconnected the fan impeller will continue to rotate for a period of time before coasting to a stop. Do not access the fan until

the fan wheel has come to a complete stop.

The Typhoon Central Dust Collector is a wet dust collector which uses water as the medium to separate dust from air by means of mixing through

a baffle and basin. When installed and operated properly, the Typhoon Central Dust Collector operates automatically and will require very little

maintenance. However, as is the case with any mechanical equipment, it should be operated, maintained and serviced in accordance with these

instructions to ensure long life and trouble free performance and use.

The dust generated by the particular operation for which the Typhoon Central Dust Collector is employed is drawn into the collector through the inlet

ductwork, into a water bath, and then through Diversitech’s unique baffle section which through a combination of induced aerodynamic and hydrostatic

forces causes the dust to mix thoroughly with the water and separate from the air. The cleaned air is then emitted from the dust collector through the

fan and the separated dust settles to the bottom of the water bath. The dust forms a sludge which is then periodically removed from the collector.

The Typhoon Central Dust Collector can only be operated when it is filled with water to the correct level. A low water level would result in by-pass of

unfiltered air. Automatic filling allows the Typhoon Central Dust Collector to run continuously and in case of a failure event cut-out devices prevent

operation of the fan if the water level is too low.

SECTION 2 - GENERAL PRODUCT INFORMATION

2.1.1 Description

Summary of Contents for Typhoon TY-10000

Page 26: ...26 12 4 Troubleshooting Procedure...

Page 29: ...29 NOTES...