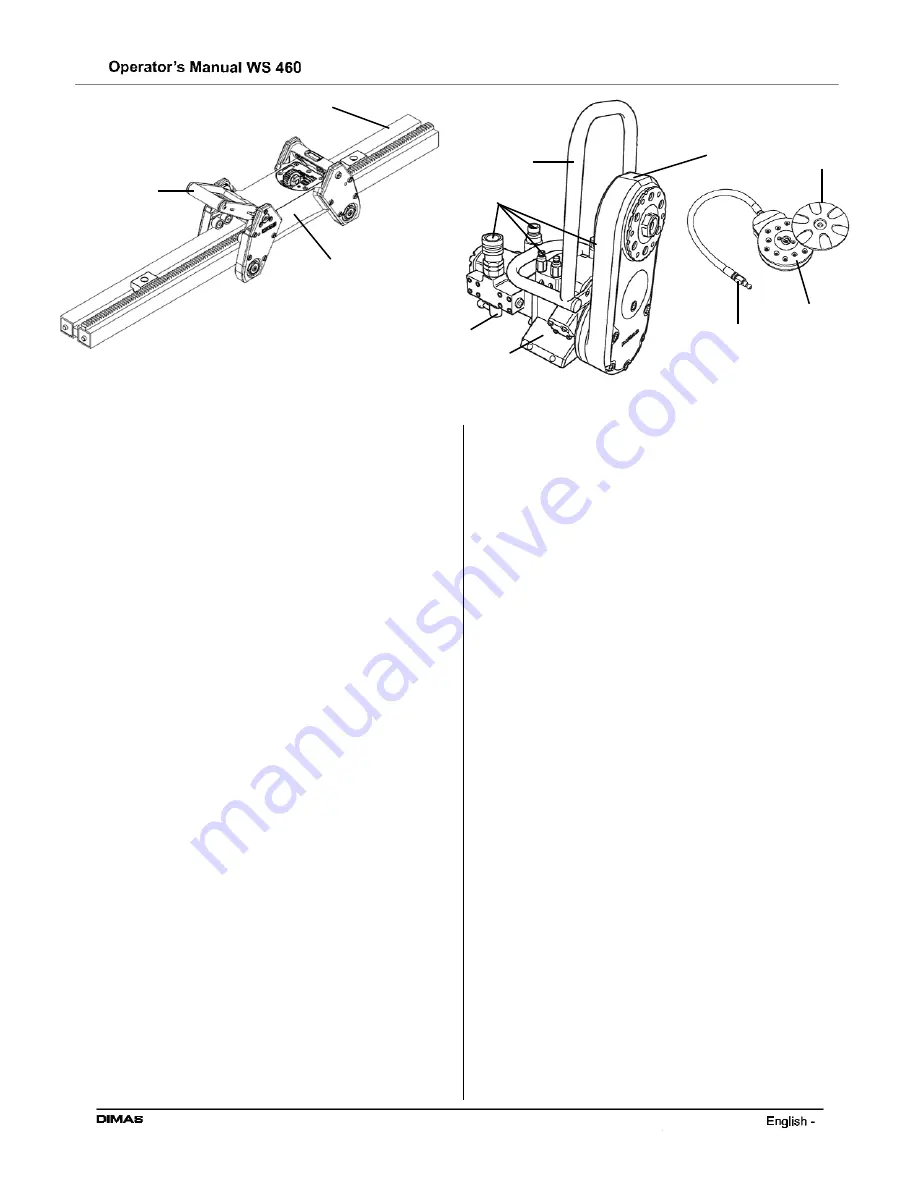

The saw consists of the following components parts:

1. Saw Carriage

A separate saw carriage is one of the new features

of the WS 400 series. A separate saw carriage

results in a system that is easier and faster to

setup than other saws. The saw carriage supplied is

adjusted at the factory. The saw carriage features

two levels to help facilitate mounting the track

straight when cutting horizontally and vertically.

2. Locking Handle

Used to lock the saw unit in the saw carriage.

3. Saw Head

Houses the feed motors for the saw’s travel and the

arm’s 360° rotation as well as two slip clutches that

prevent the saw from being damaged if it should jam.

4. Speed Valve

The speed of saw motor is controlled with this

valve. There are two or three positions of the motor

(depending on saw configuration). The speed of

rotation to be used depends on the blade size used.

5. Cutting Arm

The cutting arm allows blades up to 40” (1000 mm) to

be used as the start blade. The cutting arm can be

rotated 360° in either direction, which gives great

freedom when planning the cut. As the cutting arm

has been moved in 2.5” (63.5 mm) closer to the track

compared to earlier saw models, the forces that affect

the saw are reduced significantly, which give

straighter cuts and less friction losses between the

blade body and the cut.

7

6. Blade Guard Guide

The blade guard is suspended from this guide.

When the saw is to be lifted the blade guard

guide acts as a handle. The blade guard guide

also acts as a protective cage for the saw.

7. Track

The machine is supplied with two tracks, one 40”

(1m) and one 90”(2.3m).

8. Quick-Attach Blade Flange

The quick-attach blade flange is another new

feature on the WS 400 series. The flange unit can

be mounted on the blade before the blade is

fitted on the saw. Doing so permits easier

assembly of the blade on the saw especially when

flush cutting. The flange also is ready for flush

cutting by simply removing the outer blade flange.

9. Outer Blade Flange

Locks the saw blade on the quick-attach blade

flange.

10. Hydraulic Hose Connections

The hydraulic flow in the large hoses drives the

blade while the hydraulic flow in the smaller hose

drives the direction of the saw and the arm

rotation.

The hoses connected to the saw’s small female

couplings (closest to the arm) drive the arm

rotation while those connected to the small male

couplings (furthest from the arm) drive the saw

along the track.

11. Water Connector

Water coolant for the blade is connected here. In

addition to cooling blade, the water also helps to

control the dust.

1

7

2

6

10

4

3

5

9

11

8

Summary of Contents for Dimas WS 460

Page 1: ......