21

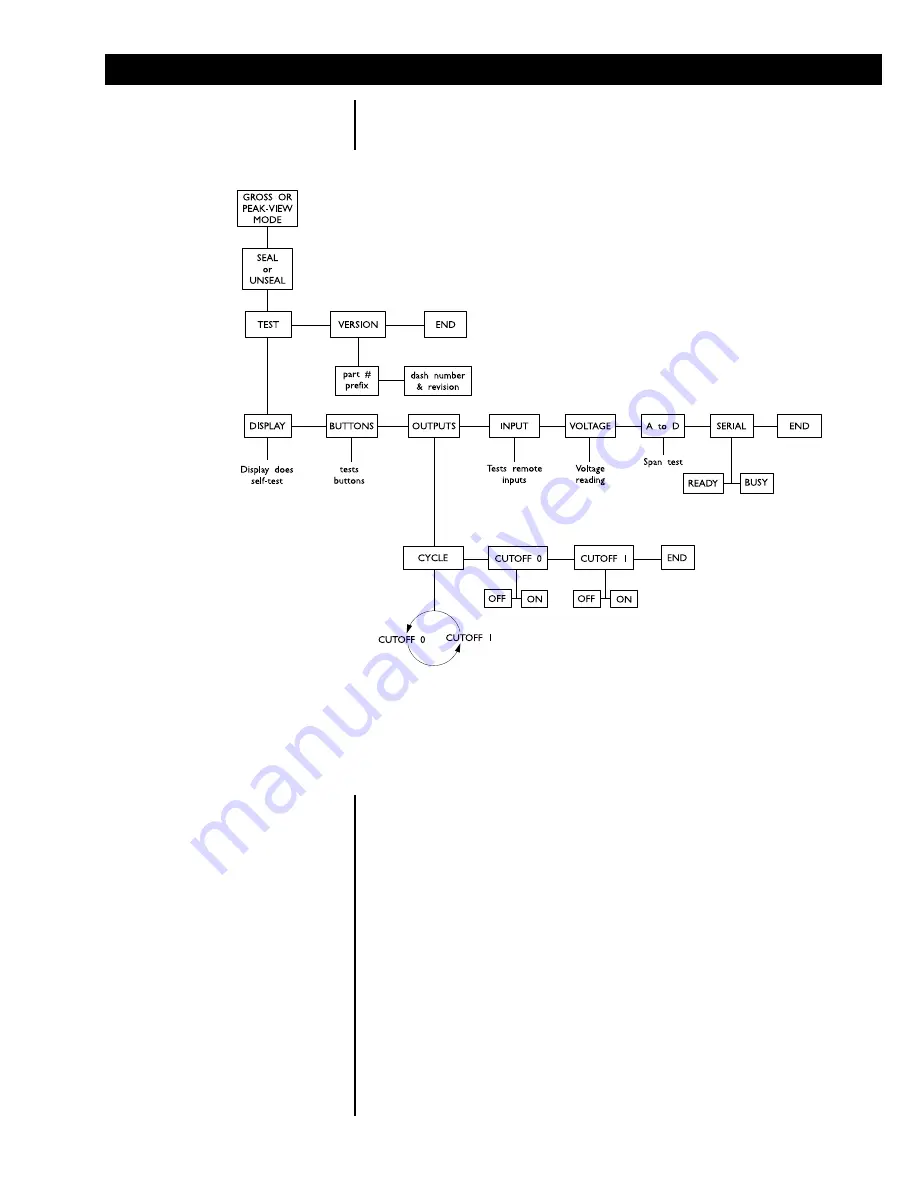

Test mode allows you to test various functions of the FI-90. A flowchart of the

test mode menu is shown in Figure 11, followed by instructions for getting

around in the test mode and executing tests.

1. Enter the test mode from gross or peak-view mode by pressing and

holding

MENU

until

tESt

is displayed.

SEAL

or

unSEAL

is displayed

briefly while you hold the key.

2. Move to the right through the menu selections by briefly pressing

MENU

.

Move to the left through the menu selections by pressing

MENU

for one

second. Scroll continuously to the left by pressing and holding

MENU

.

3. Move down a level in the test mode hierarchy by pressing

PRINT /

SELECT

. Move up a level in the hierarchy: from any display in the

hierarchy, by pressing and holding

PRINT / SELECT

for approximately

1.5 seconds; or from the

End

display, by pressing

PRINT / SELECT

.

4. Press

MENU

to toggle between the options under any test parameter,

such as the

ready

and

busy

options under the serial test parameter.

5. Press

GROSS / PEAK

to return to gross or peak-view mode at any time.

Descriptions and instructions follow for the tests and parameters you see in

the test mode flowchart.

Using Test Mode for Indicator Diagnostics

Figure 11

Flowchart of the Test Mode Menu

Summary of Contents for FI-90

Page 1: ...Dillon FI 90 Force Indicator User s Manual ...

Page 23: ...23 ...