9

DHOLLANDIA

1.7

DESCRIPTION AND WHEELCHAIR LIFT TERMINOLOGY

1.7.1

General

DHOLLANDIA lifts are developed and manufactured using state-of-the-art technology, high quality materials and components,

and highly skilled workmanship. They comply with the European CE safety regulations mentioned in the Declaration of

Conformity issued with each lift (unless otherwise agreed for lifts exported outside the CE region).

The DH-CH003 and the DH-CH100... series comprise of a range of cassette lifts, designed for a wide range of multi passenger

vehicles, busses and coaches, with different mounting positions in or under the vehicle, but functioning in a very similar way.

In travel position, the platform and lift frame are safely stored inside a sealed “cassette”. Upon deployment, the platform and lift

frame are slid out of the cassette. Then a bridge plate and handrails are unfolded to make the lift ready for use.

This cassette can be mounted in various positions depending on the type of vehicle: under the chassis, in the luggage

compartment, or integrated in one of the access stairs of the bus.

Main details and terminology: see below.

DH-CH003* / CH101* / CH102* / CH103*

●

TERMINOLOGY

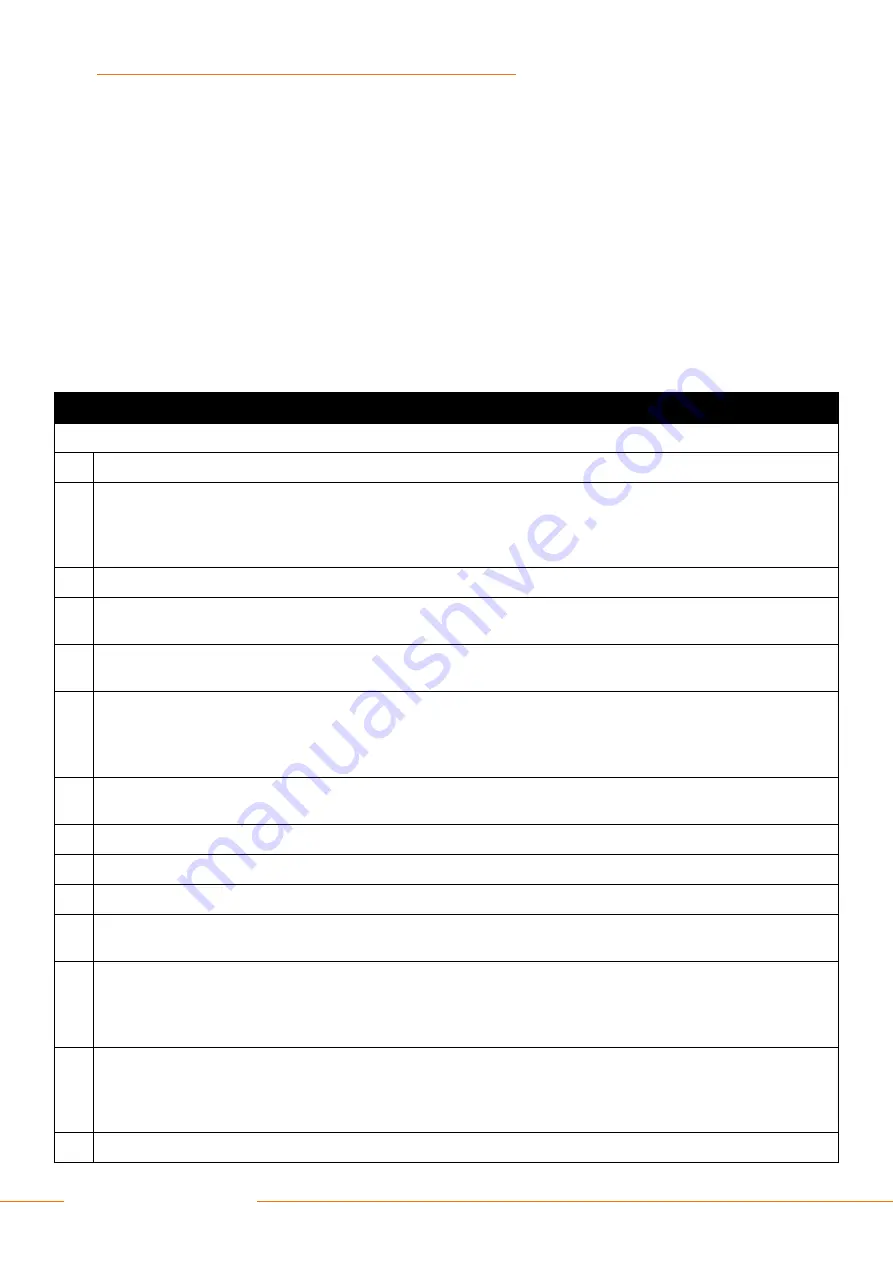

See figure below for parts corresponding to numbers in this table

#

Description

1

Cassette: sealed box housing the lift frame and platform when stowed in travel position, and protecting the mechanism

against adverse weather conditions.

The cassette is equipped with slide rails and a retraction system to slide the lift frame and the platform from a travel position

deep inside the cassette to a work position at the outboard edge of the cassette, and vice versa.

2

Mounting brackets: brackets used to mount the cassette to the vehicle.

3

Lift frame: steel assembly incorporating the lift arms and lift cylinders, who together carry the platform. The lift frame is

moved in and out of the cassette by means of an electric motor and gearwheel system.

4

Lift arms + lift cylinders: 2 lift arms L+R actuated by the lift cylinders, used to lift / lower the platform and its load (=

functions UP / DOWN).

5

Platform: carries the load during lifting / lowering. The platform is covered with an aluminium top plate with a non-slip

surface. It is further equipped with a bridge plate, handrails and a roll stop flap.

The platform can be 1 single section [# 5] or an extensible platform [# 6] with a platform main section [# 6a] and an extensible

point [# 6b].

6

Extensible platform: extensible platforms are used to shorten the mounting space needed to fit a cassette lift with a certain

platform depth. It is standard on lift type DH-CH003*.

6a

Platform main section: inboard main section of the extensible platform, attached to the lift arms.

6b

Extensible point: extensible point of the platform, pulled out upon deployment of the lift, and pushed back upon stowage.

7

Flashing platform lights: used to make the platform visible to other parties in traffic.

8

Bridge plate: plate mounted at the inboard platform edge, used to bridge any gap between the platform and the vehicle

floor when the platform is raised to its maximum height.

9

Handrails: Rails mounted at both sides of the platform. Lift occupants should hold on to these handrails to prevent them

from falling off the platform. Handrails must be deployed manually and secured in vertical position prior to using the lift, they

must be stowed manually before retracting the lift back into its travel position.

On DH-CH101*, foldable extensions [# 9a] to the handrails are available as an option (option OWP013).

10

Roll stop: roll stop mounted at the outboard platform edge. The roll stop is tilted up automatically when the platform leaves

the ground, it is tilted down automatically when the platform touches the ground.

The roll stop prevents the wheelchair from slowly and unexpectedly rolling off the platform during lifting and lowering. It is

not designed to stop fast and powered movements.

11

Automatic cassette lock: in regular conditions, the lift frame and platform are automatically locked inside the cassette by