9

English

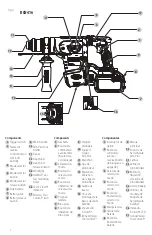

Belt Hook (Fig. E)

Optional Accessory

WARNING: To reduce the risk of serious personal

injury, ONLY use the tool’s belt hook to hang the

tool from a work belt. DO NOT

use the belt hook

for tethering or securing the tool to a person or object

during use.

DO NOT

suspend tool overhead or suspend

objects from the belt hook.

WARNING: To reduce the risk of serious personal

injury,

ensure the screw holding the belt hook is secure.

iMPORTAnT:

When attaching or replacing the belt hook,

only use the screw

19

that is provided with the belt hook. Be

sure to securely tighten the screw.

To accommodate left‑ or right‑ handed users the belt

hook

18

can be attached to the tool using one of the

slots below the main handle on left or right side and using

the provided screw

19

installed on the underside of the

main handle.

If the belt hook is not desired at all, it can be removed from

the tool.

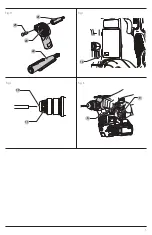

To Adjust the Depth Rod (Fig. D)

1. Push in and hold the depth rod release button

13

on the

side handle.

2. Move the depth rod

12

so the distance between the

end of the rod and the end of the bit equals the desired

drilling depth.

3. Release the button to lock rod into position. When

drilling with the depth rod, stop when end of rod reaches

surface of material.

Bit and Bit Holder

WARNING:

Burn Hazard.

ALWAYS

wear gloves when

changing bits. Accessible metal parts on the tool and

bits may get extremely hot during operation. Small bits

of broken material may damage bare hands.

The hammerdrill can be fitted with different bits depending

on the desired application.

Use sharp drill bits only.

Bit Recomendations

• For wood, use twist bits, spade bits, power auger bits or

hole saws.

• For metal, use high‑speed steel twist drill bits or

hole saws. Use a cutting lubricant when drilling metals.

The exceptions are cast iron and brass which should be

drilled dry.

• For masonry, such as brick, cement, cinder block, etc., use

carbide‑tipped bits rated for percussion drilling.

Bit Holder (Fig. J)

nOTE:

Special adapters are needed to use with straight

shank bits and hexagonal screwdriver bits.

To insert a Drill Bit or Other Accessory:

1. Insert the shank of the SDS PLUS bit about 3/4" (19 mm)

into tool holder

10

.

2. Push down and rotate bit until it locks in place. The bit

will be securely held.

3. To release bit, pull the sleeve

11

back and remove

the bit.

Side Handle (Fig. A, D)

WARNING:

To reduce the risk of personal injury,

ALWAYS

operate the tool with the side handle properly

installed. Failure to do so may result in the side handle

slipping during tool operation and subsequent loss of

control. Hold tool with both hands to maximize control.

The side handle

6

clamps to the front of the gear case

and may be rotated 360˚ to permit right‑ or left‑hand use.

The side handle must be tightened sufficiently to resist the

twisting action of the tool if the accessory binds or stalls. Be

sure to grip the side handle at the far end to control the tool

during a stall.

To loosen side handle, rotate counterclockwise.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories.

An

accidental start‑up can cause injury.

Wall Mounting

Some

D

e

WALT

chargers are designed to be wall mountable

or to sit upright on a table or work surface. If wall mounting,

locate the charger within reach of an electrical outlet, and

away from a corner or other obstructions which may impede

air flow. Use the back of the charger as a template for the

location of the mounting screws on the wall. Mount the

charger securely using drywall screws (purchased separately)

at least 1” (25.4 mm) long, with a screw head diameter of

0.28–0.35” (7–9 mm), screwed into wood to an optimal

depth leaving approximately 7/32” (5.5 mm) of the screw

exposed. Align the slots on the back of the charger with the

exposed screws and fully engage them in the slots.

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

battery pack in a warm environment such as in a metal

shed or an uninsulated trailer.

2. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp

or other appliance;

b. Check to see if receptacle is connected to a light

switch which turns power off when you turn out

the lights;

c. If charging problems persist, take the tool, battery

pack and charger to your local service center.

3. You may charge a partially used pack whenever you

desire with no adverse effect on the battery pack.

Charger Cleaning Instructions

WARNING:

Shock hazard. Disconnect the charger

from the AC outlet before cleaning. Dirt and grease

may be removed from the exterior of the charger using

a cloth or soft non‑metallic brush. Do not use water or

any cleaning solutions.

Summary of Contents for DCH416

Page 5: ...3 Fig H 16 Fig I Fig J Fig K 10 6 9 11 20 22 21 25 ...

Page 39: ...37 ...