4

2 INSTALLATION

This furnace is a true multi-position unit, in that it will

function in an upflow, downflow or horizontal configuration

to the left or the right. Only a few modifications are

required during installation to change from one position to

another. The unit is shipped in the upflow configuration

and instructions as to how to change to the other positions

are included in this manual.

The unit is shipped with a burner and its controls. It

requires a 115VAC power supply to the control panel and

thermostat hook-up as shown on the wiring diagram, one

or more oil line connections, suitable ductwork and

connection to a properly sized vent.

All local and national code requirements governing the

installation of oil burning equipment, wiring and the flue

connection MUST be followed. Some of the codes that

may apply are:

CSA B139:

Installation code for oil burning

equipment.

ANSI/NFPA 31: Installation of oil burning equipment.

ANSI/NFPA 90B: Warm air heating and air conditioning

systems.

ANSI/NFPA 211: Chimneys, Fireplaces, Vents and solid

fuel burning appliances.

ANSI/NFPA 70: National Electrical Code.

CSA C22.1 :

Canadian Electrical Code.

or CSA C22.10

Only the latest issues of these codes may be used.

2.1 POSITIONING

THE

FURNACE

WARNING

Fire and explosion hazard.

The furnace must be installed in a level position, never

where it will slope toward the front.

Do not store or use gasoline or any other flammable

substances near the furnace.

Non-observance of these instructions will potentially

result in death, bodily injury and/or property damage.

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. It must be installed in such a manner

as to protect its electrical components from water. Outdoor

installation will lead to a hazardous electrical condition and

to premature failure of the equipment.

The minimum clearances from combustible material

for each of the positions are specified in Table 4.

If the furnace is installed in a basement or on a dirt floor, in

a crawl space for example, it is recommended to install the

unit on a cement base 2.5 cm to 5.0 cm (1" to 2") thick.

The unit must be installed in an area where the ambient

and return air temperatures are above 15°C (60°F). In

addition, the furnace should be installed as closely as

possible to the vent, so that the connections are direct

and kept to a minimum. The heater should also be

located close to the centre of the air distribution system.

2.1.1

Installation in an enclosure

The unit can be installed in an enclosure such as a

closet. However, 2 ventilation openings are required for

combustion air. The openings should be located in front

of the furnace approximately 15 cm (6") above the floor

and 15 cm (6") below the ceiling. Figure 1 indicates the

minimum dimensions required and the location of the

openings.

Figure 1

Location and dimensions of ventilation

air openings in a closet door

2.2 CONFIGURATIONS

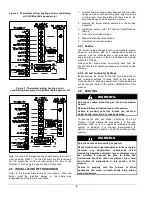

2.2.1 Upflow Installation

The return air opening may be located on either side of

the furnace. Care should be taken not to damage the

wires inside, while cutting the opening. Install the filter

rack supplied with the unit according to the instructions

provided with it. It is also recommended to install the

blower door before handling or moving the unit. Refer to

figure 2 for additional details.

Figure 2 Upflow Installation

DNS-1227A

Burner position

Filter 24X24

Combustible or non-

combustible floor

Summary of Contents for AMP154SD

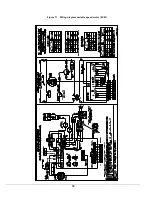

Page 17: ...17 Figure 9 Furnace Dimensions ...

Page 18: ...18 Figure 10 Wiring diagram 4 speed motor PSC ...

Page 19: ...19 Figure 11 Wiring diagram variable speed motor ECM ...

Page 20: ...20 Figure 12 Parts list with 4 speed motor PSC B500111A ...

Page 22: ...22 Figure 13 Parts list with variable speed motor ECM B50112A ...